Preparation method of apple vinegar and product thereof

An apple cider vinegar and apple technology, applied in the field of food and beverage, can solve the problems of few types of fermentation microorganisms, long fermentation time of a single strain, difficulty in industrial production, etc., and achieve the effects of increasing apple flavor, facilitating quality control, and improving fermentation flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

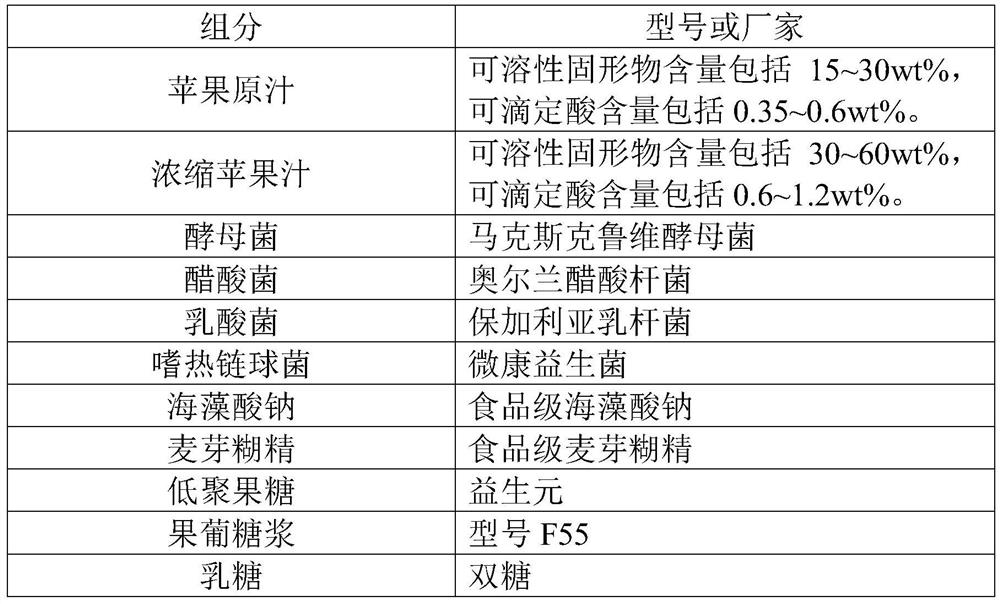

Method used

Image

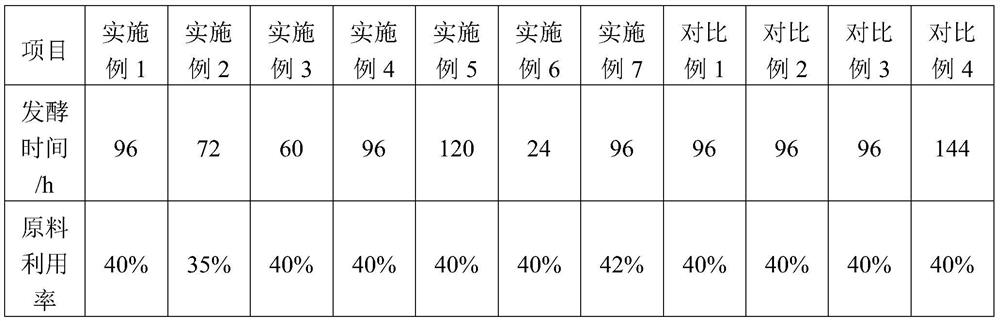

Examples

Embodiment 1

[0082] This embodiment provides an apple cider vinegar. The raw materials for the preparation of the apple cider vinegar include, in parts by weight, 30 parts of original apple juice, 10 parts of concentrated apple juice and 60 parts of water.

[0083] Described apple cider vinegar is prepared by following preparation method:

[0084] (1) Mix apple raw juice with concentrated apple juice to obtain apple raw juice, then mix it with water, filter it with a 60-mesh filter, and sterilize it at 95°C for 5 minutes to obtain a dilution; take Kluyveromyces marx, The strains of Acetobacter blueus, Lactobacillus bulgaricus and Streptococcus thermophilus were successively carried out primary culture, secondary culture and expanded culture, the temperature of the primary culture was 30°C, and the time of the primary culture was 10h. The temperature of the secondary cultivation is 30°C, the time of the secondary cultivation is 14h, the temperature of the expanded cultivation is 30°C, and t...

Embodiment 2

[0087] This embodiment provides an apple cider vinegar. The raw materials for the preparation of the apple cider vinegar include, in parts by weight, 25 parts of original apple juice, 10 parts of concentrated apple juice and 65 parts of water.

[0088] Described apple cider vinegar is prepared by following preparation method:

[0089] (1) Mix apple raw juice with concentrated apple juice to obtain apple raw juice, then mix it with water, filter it with a 40-mesh filter, and sterilize it at 90°C for 10 minutes to obtain a dilution; take Kluyveromyces marx and acetic acid bacteria The strains of Lactobacillus bulgaricus and Streptococcus thermophilus were respectively followed by primary culture, secondary culture and expanded culture. The temperature of the primary culture was 32°C, and the time of the primary culture was 12h. The secondary culture The temperature of the temperature is 32°C, the time of the secondary culture is 16h, the temperature of the expanded culture is 32...

Embodiment 3

[0092] This embodiment provides an apple cider vinegar. The raw materials for the preparation of the apple cider vinegar include, in parts by weight, 35 parts of original apple juice, 5 parts of concentrated apple juice and 60 parts of water.

[0093] Described apple cider vinegar is prepared by following preparation method:

[0094] (1) Mix apple raw juice with concentrated apple juice to obtain apple raw juice, then mix it with water, filter it with a 50-mesh filter, and sterilize it at 93°C for 8 minutes to obtain a dilution; take Kluyveromyces marx and acetic acid bacteria The strains of Lactobacillus bulgaricus and Streptococcus thermophilus were respectively followed by primary culture, secondary culture and expanded culture, the temperature of the primary culture was 30°C, the time of the primary culture was 10h, and the secondary culture The temperature of the temperature is 30°C, the time of the secondary culture is 14h, the temperature of the expanded culture is 30°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com