Online drying device and online drying method for bead wire

A technology of drying device and bead steel wire, which is applied in drying, drying machine, drying solid materials and other directions, can solve the problems of failure of drawing powder, affect product quality, and can not continue drawing, so as to ensure the normal operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

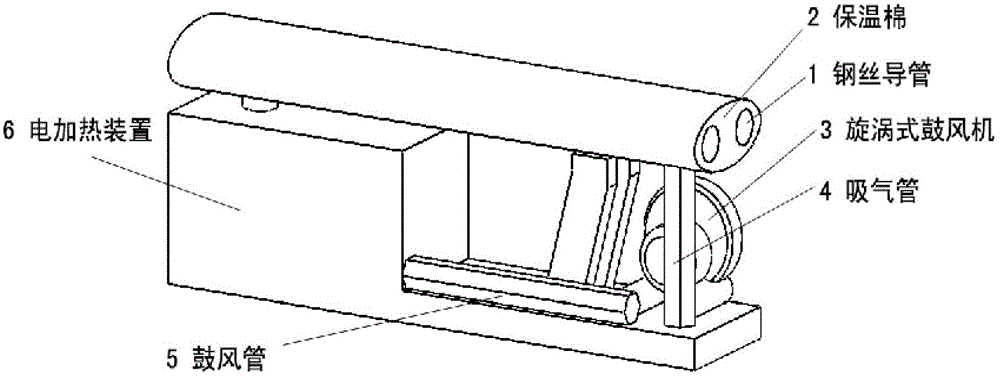

[0024] Such as figure 1 As shown, this patent is achieved in this way: the steel wire enters the steel wire conduit 1 of the device, and the air is sucked from the suction pipe 4 through the vortex blower 3, and the suction pipe 4 is located at the inner end of the steel wire conduit 1, so as to improve the vortex blower. 3 The temperature of the air at the time of inhalation. The vortex blower 3 enters the electric heating device 6 through the blast pipe 5, and its power is 10KW, so as to ensure that the moisture remaining on the steel wire surface can be dried when drawing at high speed. The device adopts upwind blowing, and the blowing direction of the vortex blower 3 is opposite to that of the steel wire, so as to improve the drying efficiency. In addition, the catheter 1 of the device is wrapped with thermal insulation cotton to play a role of thermal insulation.

Embodiment 2

[0026] On the basis of the above examples, if figure 1 As shown, an online bead wire drying device includes a base, wherein an electric heating device 6 is provided on the base and connected to the steel wire conduit 1 through a circular through pipe, preferably two steel wire conduits 1 are arranged symmetrically.

[0027] In the online drying device, an air suction pipe 4 is provided on the base to support and connect to the steel wire conduit 1 .

[0028] The online drying device, wherein, the suction pipe 4 is connected to the vortex blower 3 sucked into the air in the steel wire conduit, which is actually an air intake process, and the suction pipe 4 is due to the effect of the heating device of the vortex blower 3 at the rear end. The temperature in the suction pipe 4 is higher than the ambient temperature, so the intake air should be taken from the suction pipe 4 to reduce energy consumption and save costs.

[0029] The online drying device, wherein, the vortex blower ...

Embodiment 3

[0033] On the basis of the above embodiments, the present application also provides a bead wire online drying method, which includes the following steps:

[0034] A: The steel wire enters the steel wire catheter;

[0035] B: The vortex blower sucks air into the steel wire duct through the suction pipe;

[0036] C: The vortex blower enters the electric heating device to blow through the blowing pipe, and dries the moisture remaining on the surface of the steel wire.

[0037] The online drying method, wherein in the step B, the temperature of the air sucked into the steel wire conduit is controlled at 60-80°C.

[0038] The online drying method, wherein, in the step C, the blowing direction is opposite to the steel wire running direction.

[0039] The online drying method, wherein the purging temperature in the step C is controlled at 130-140°C.

[0040] Preferably, an air suction pipe 4 is also provided on the base to support and connect to the inside of the steel wire condui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com