Biomass hot air stove system

A technology of hot blast stove and biomass, which is applied in the direction of air heater, fluid heater, lighting and heating equipment, etc. It can solve the problems of complex structure of hot blast stove, low heat exchange efficiency, and restrictions on popularization and use, and achieves a small footprint , high heat exchange efficiency, compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below through examples.

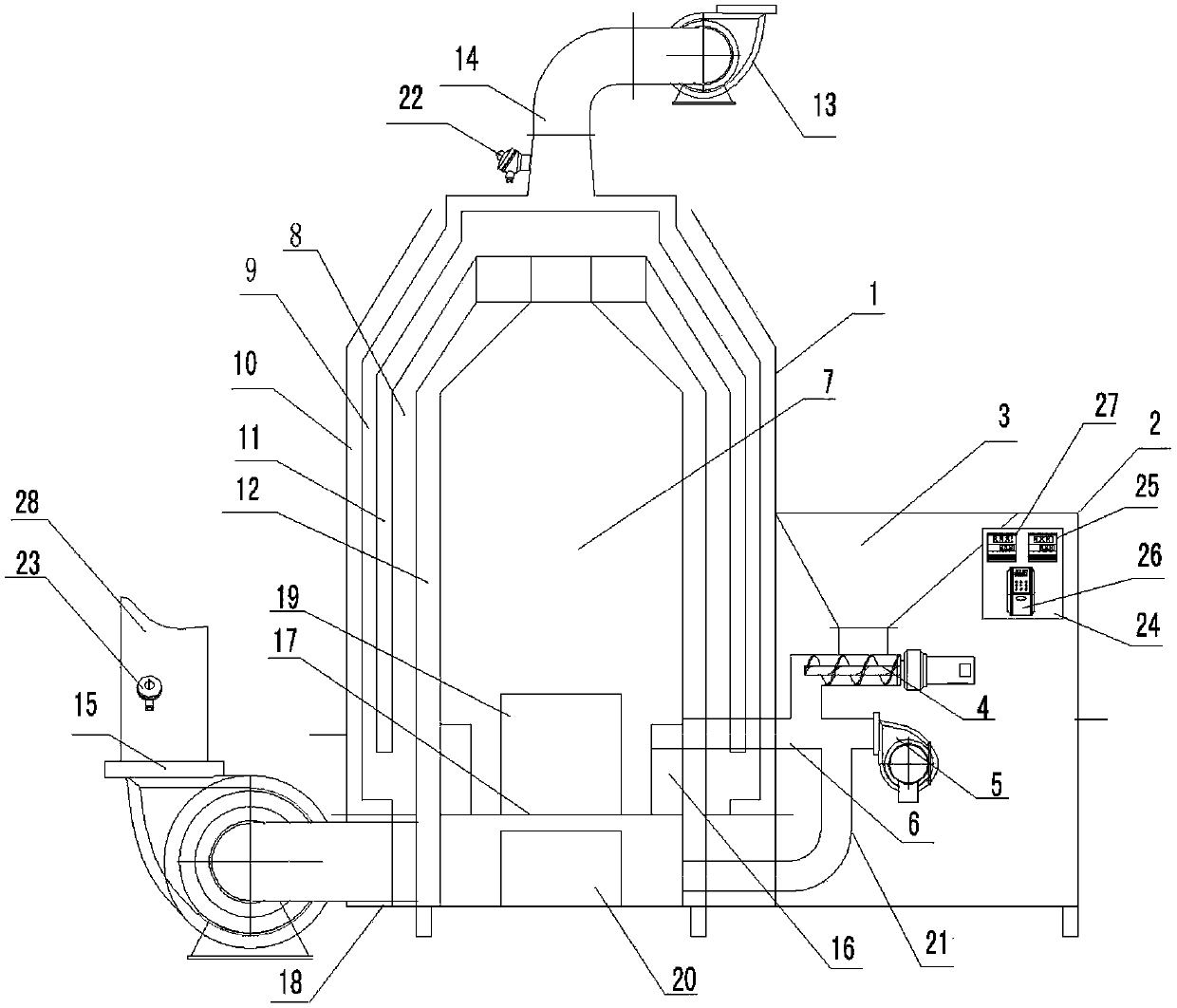

[0020] Such as figure 1 As shown, the biomass hot stove system of the present invention includes a heat exchange furnace main body 1 and a feeding system 2, and the specific structure and connection relationship are as follows:

[0021] The heat exchange furnace main body 1 includes a furnace 7, a first return flue 8, a second return flue 9, a first return air duct 10, a second return air duct 11, a third return air duct 12, and a flue gas induced draft fan 13. Flue gas induction pipe 14, hot air induced draft fan 15, furnace fire-resistant wall 16, fire grate 17, ash discharge device 18, furnace door 19, dust removal door 20 and hot air outlet 28, the furnace 7 is equipped with fire grate 17 , furnace fire-resistant wall 16, furnace door 19 and ash removal door 20, furnace 7 is connected with ash discharge device 18, furnace 7 is connected with first return flue 8, firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com