Rocket stamping combination engine with annular injection structure

A technology of ejection structure and engine, applied in the direction of combined engine, ramjet engine, mechanical equipment, etc., can solve problems such as difficulty in technical realization, and achieve the effects of improving space utilization, increasing maneuverability, and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

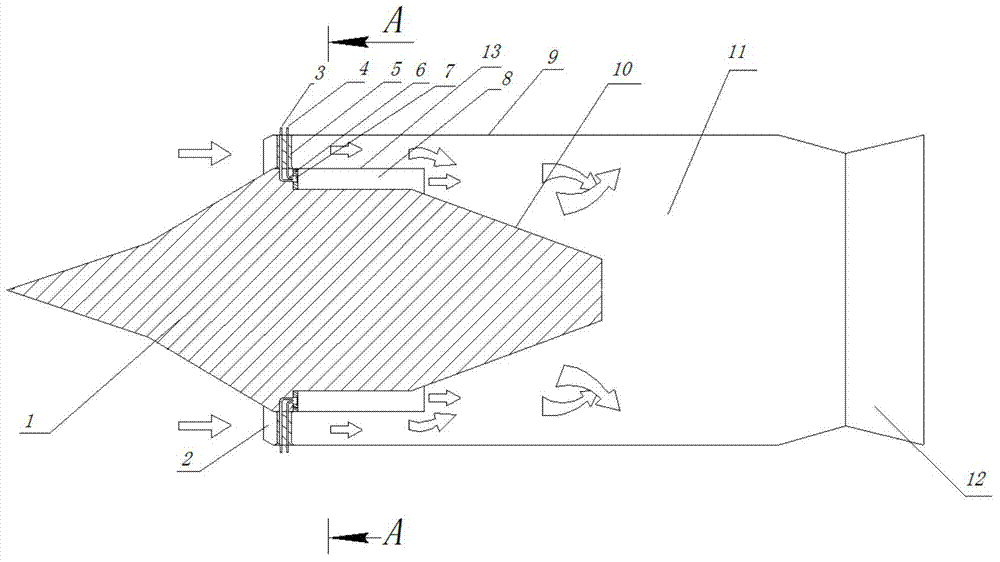

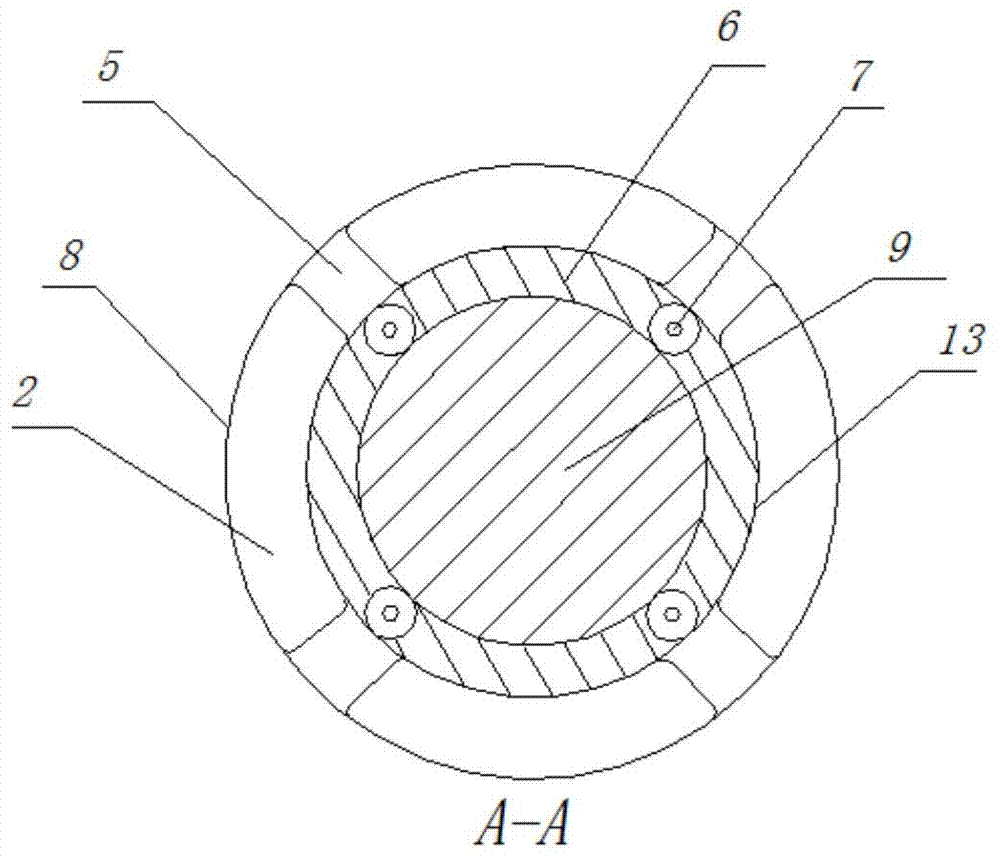

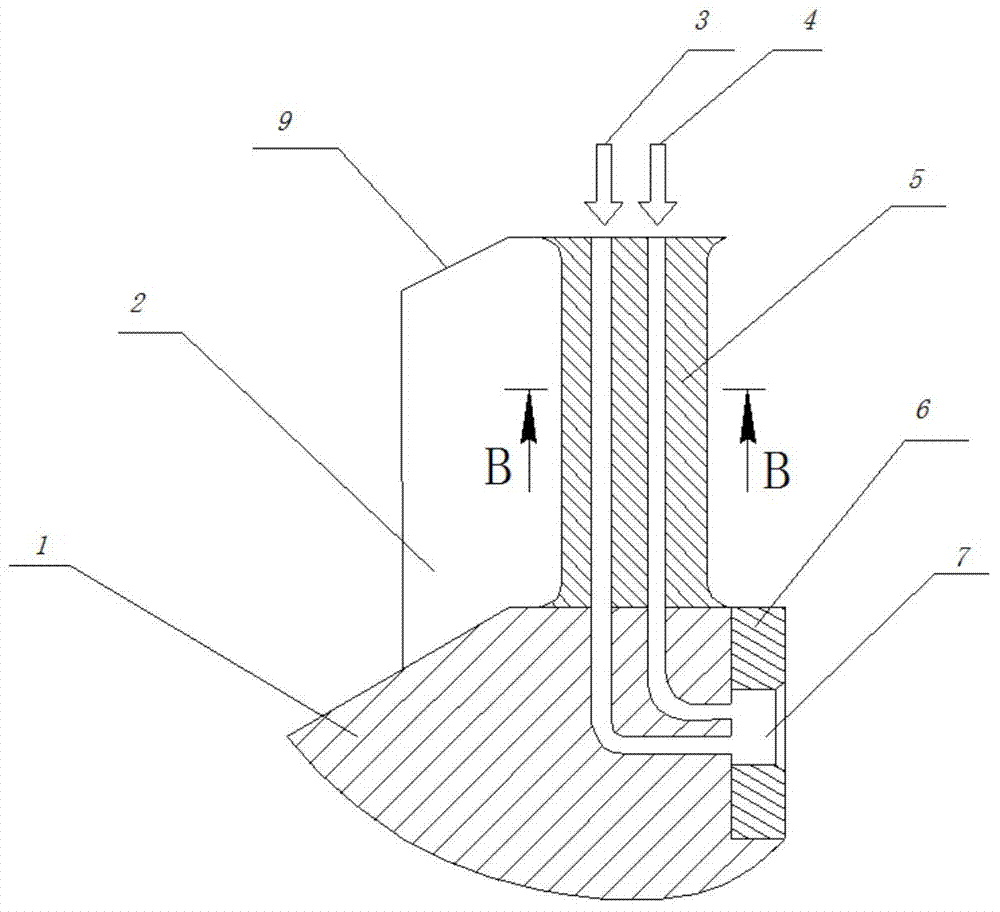

[0012] The rocket ramjet combination engine that the present invention proposes has the annular ejection structure, and its structure is as follows figure 1 As shown, it includes an engine casing 9, an inner casing 13, a rectifying head, a fixed guide column 5 and a fixed ring 6. The engine housing 9 is relatively fixed with the rectifier by the fixed guide column 5, and the fixed guide column 5 is provided with an oxidant inlet 3 and a fuel inlet 4, and the front end of the engine housing is an air inlet 2, such as figure 2 shown in . The front body 1 of rectifying head stretches out the front end of engine casing 9, and the rear body 10 of rectifying head is stepped, and step type rectifying head rear body 10 inserts in the engine casing 9, and the rear end of engine casing 9 is trumpet-shaped supersonic nozzle 12. The inner shell 13 is fixed on the middle part of the straightening head by the fixing ring 6, and the fuel oxidant mixing injection port 7 is arranged in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com