Safety protective cover on punch press and application method thereof

A safety protection and protective cover technology, applied in safety equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of operator injury, easy safety accidents, burrs and debris splashing, etc., to avoid safety accidents and improve production. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

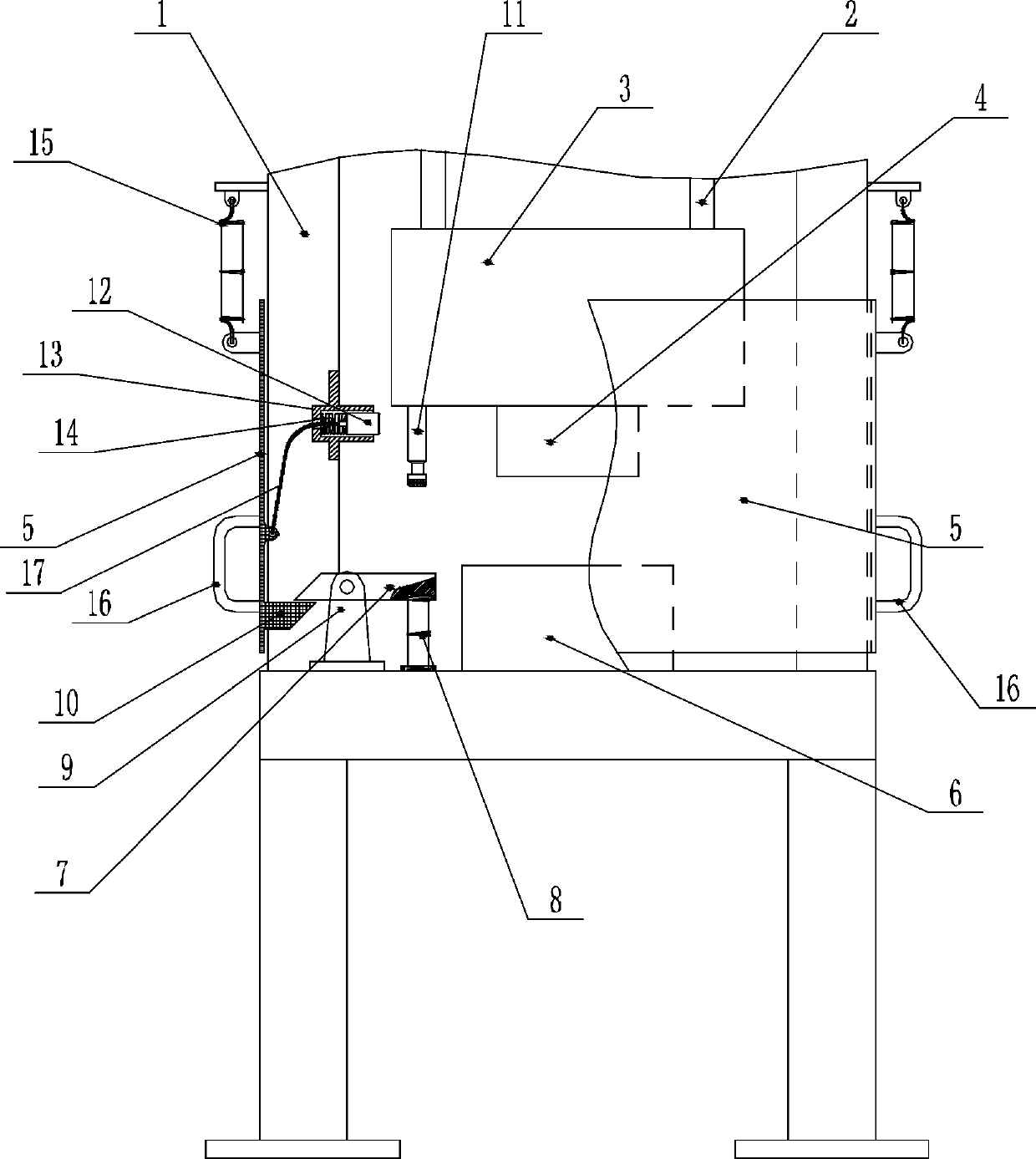

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 ,

[0015] A safety shield on a punching machine comprises a frame 1 on which a guide rod 2, a slide block 3, an upper die 4, a protective cover 5, a lower die 6 and a limiting device are arranged.

[0016] The guide rod 2 is fixed at the top position of the frame 1, the slide block 3 is slidably connected to the guide rod 2, and the slide block is driven by a stamping device of a punch press, and the punching device is a prior art and is not used. To repeat too much, the upper mold 4 is arranged on the bottom surface of the slider 3, the lower mold 6 is arranged on the operating platform of the frame 1 and is located directly below the upper mold 4, and the guide rod 2 can make the The slider 3 slides smoothly during the punching process.

[0017] The left side of the lower mold 6 is provided with a fastening device, the faste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com