Cross beam type salt-core pressing die and salt core production method adopting pressing die

A technology for pressing molds and salt cores, which is applied in the field of salt core pressing molds for aluminum pistons and the production process of salt cores. It can solve the problems of complex structure of cold salt cores and inability to produce them, so as to save processing procedures and reduce energy consumption. Consumption, guaranteed high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the embodiments given by the accompanying drawings.

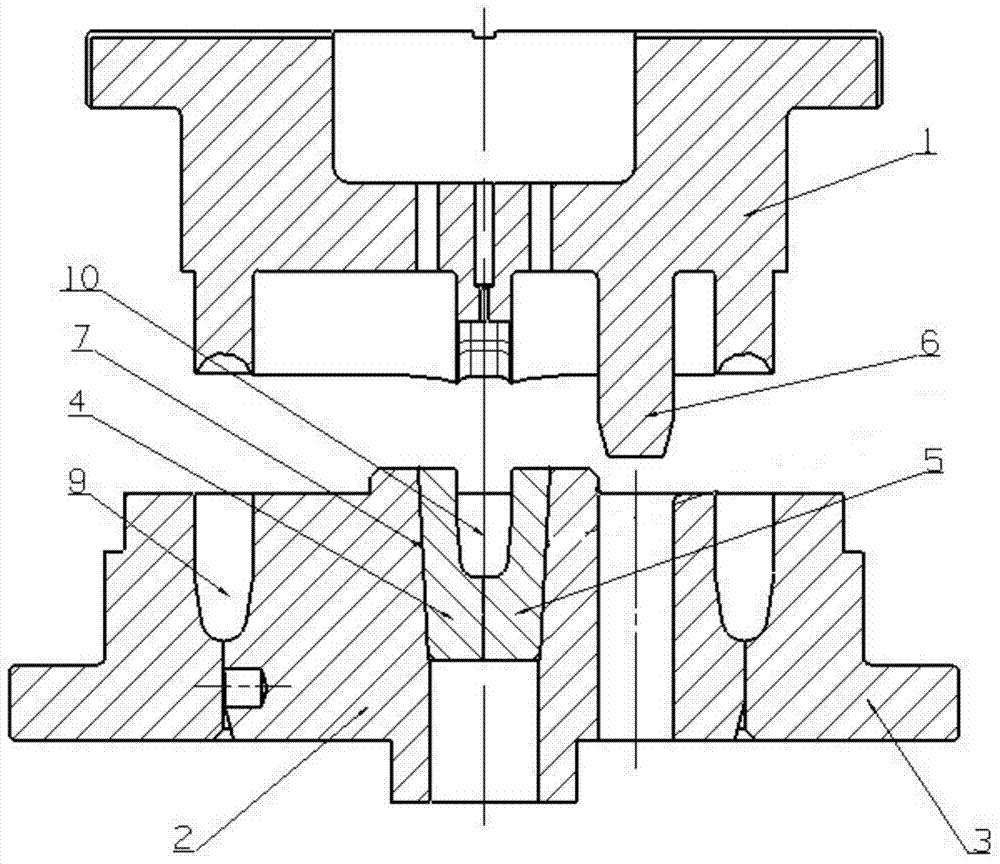

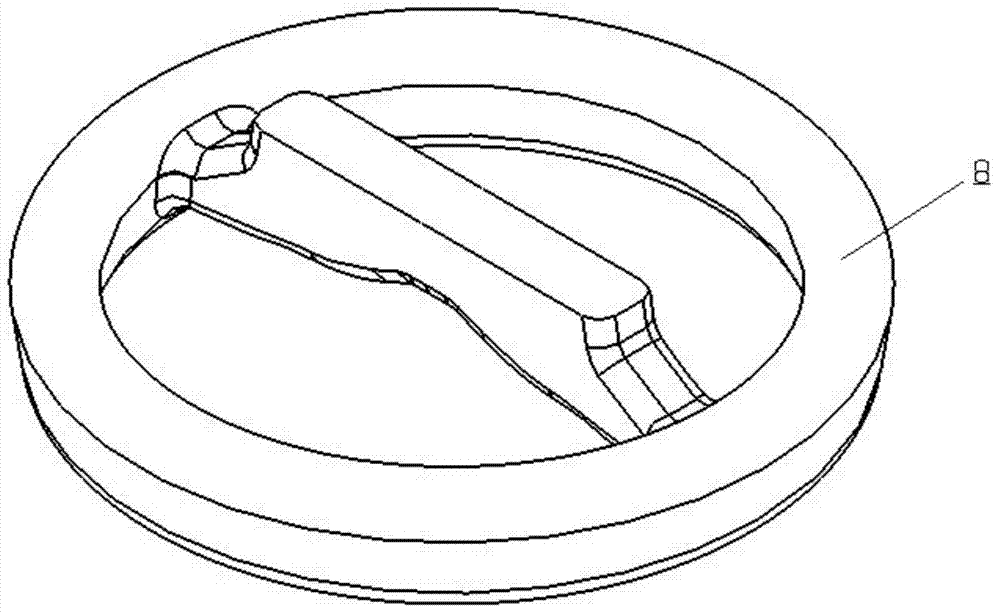

[0034] A beam type salt core pressing mold, such as figure 1 As shown, including the upper die 1, the lower die outer ring 3, the lower die inner ring 2 and the loose block, the top of the outer wall of the lower die inner ring 2 is provided with a first groove extending along its axis direction; The top of the inner wall of the lower die outer ring 3 is provided with a second groove matching the first groove; the first groove and the second groove form a first annular groove, and the upper pressure The bottom surface of the mold 1 is provided with a second annular groove corresponding to the opening of the first annular groove, which communicates with the first annular groove, and the second annular groove is connected to the first annular groove. After the grooves are docked, a salt core mold cavity I9 is formed. The cavity volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com