Low temperature plasma device for treating volatile organic

A technology of low-temperature plasma and volatile organic compounds, applied in the direction of plasma, chemical/physical/physicochemical processes of energy application, separation methods, etc., can solve problems such as breakdown, affecting processing efficiency, easy to form arcs, etc., and achieve gas The effect of improving discharge, improving processing efficiency, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

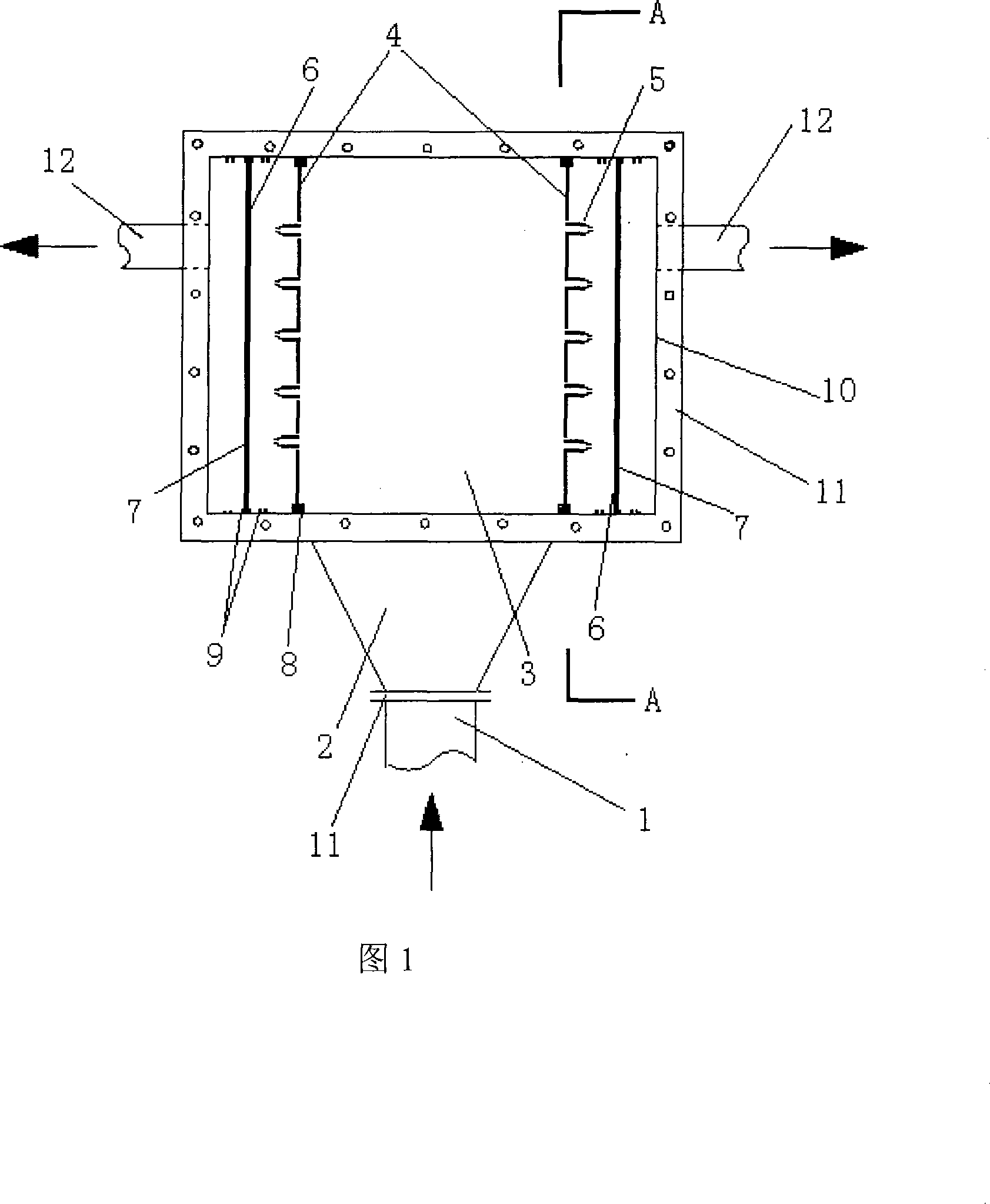

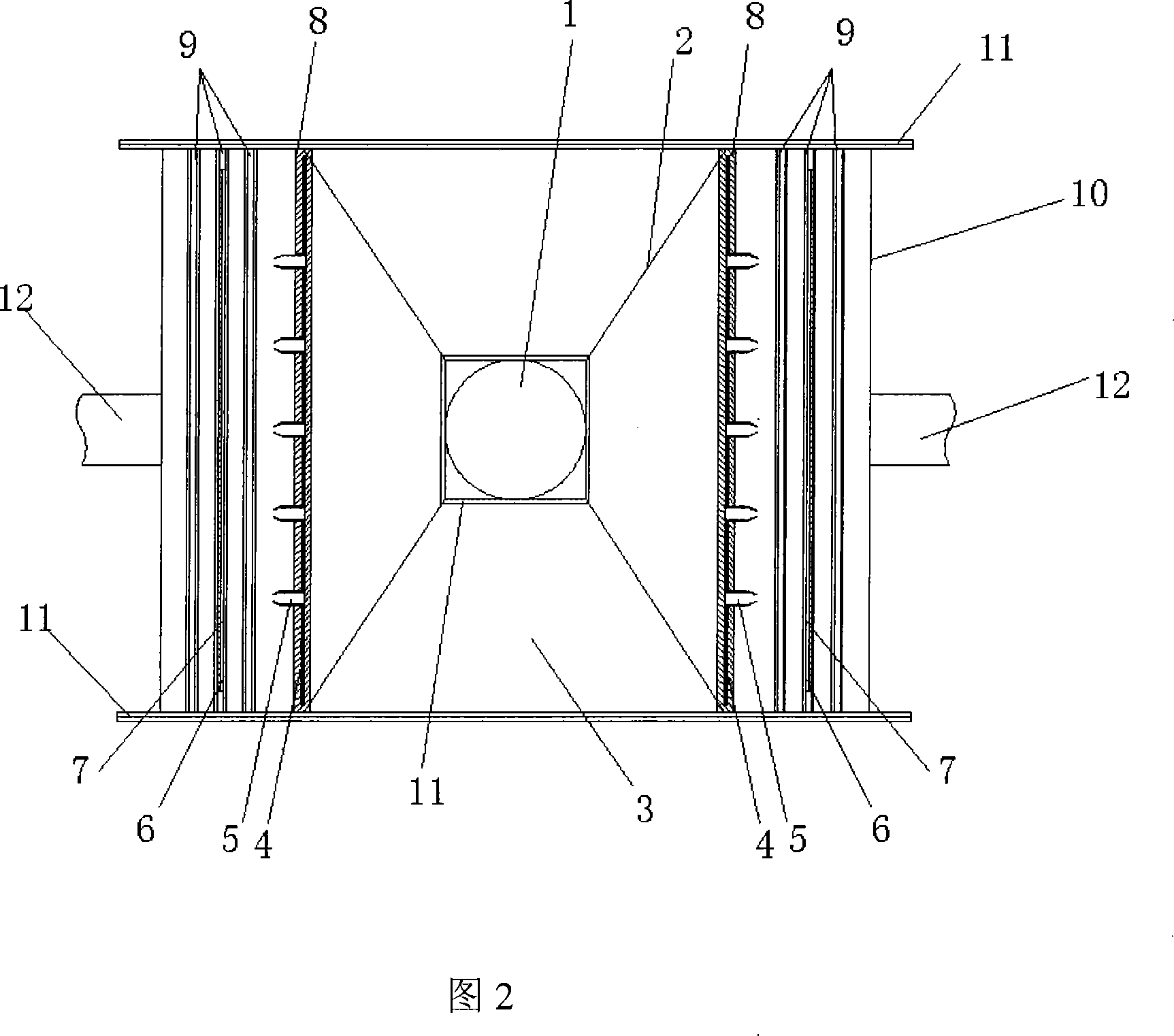

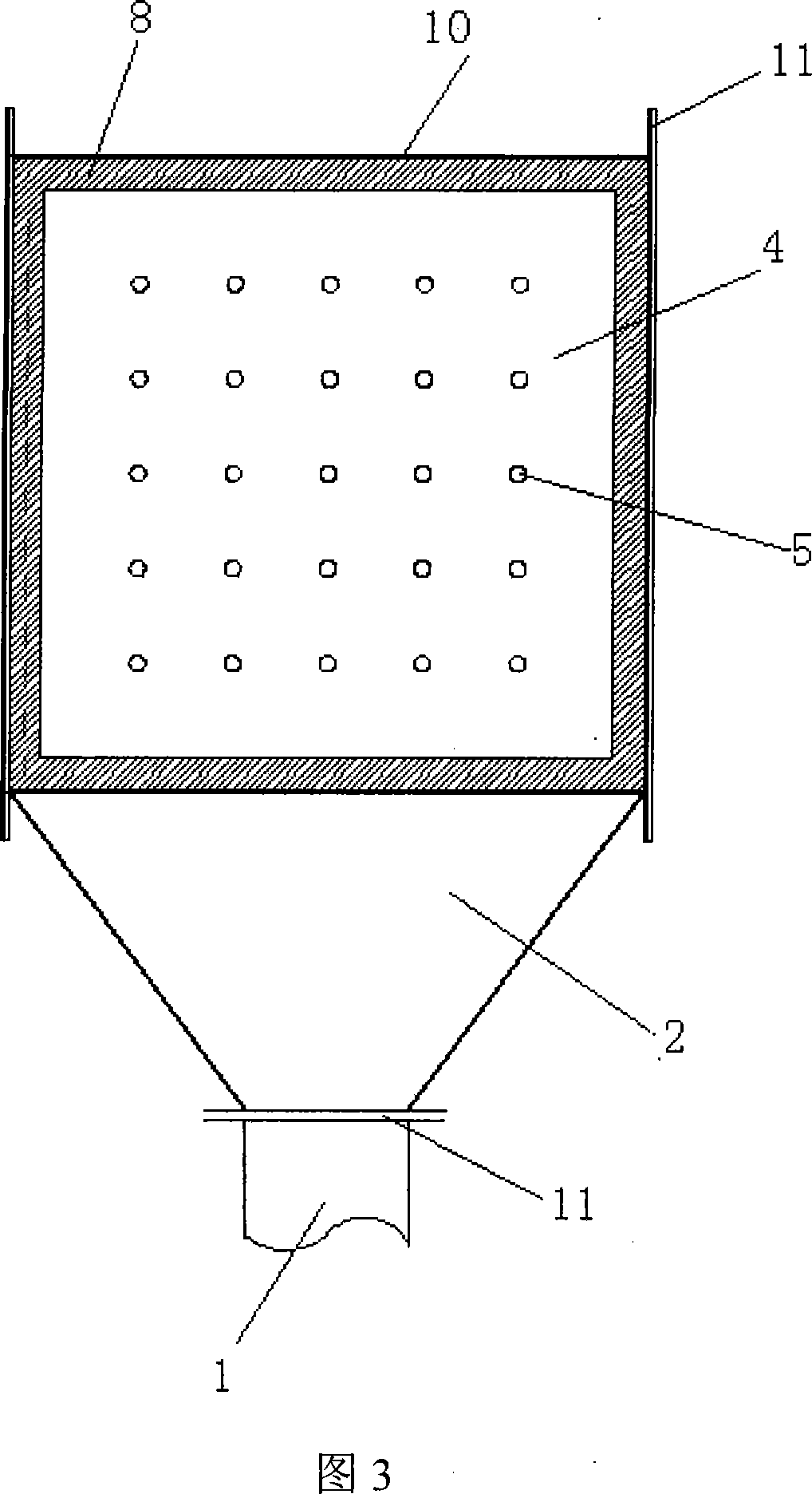

[0024] This embodiment will be described in detail below with reference to FIGS. 1 to 5 .

[0025] As shown in Figure 1 and Figure 2, this embodiment mainly includes an air inlet 1, a diffuser 2, and a reactor shell 10, the air inlet 1 is connected to the diffuser 2 through a flange 11, and the diffuser 2 It is fixedly connected with the reactor shell 10. The reactor shell 10 is a cuboid structure, and its internal structure is symmetrically distributed. Insulation slots 8 and 9 are provided on the upper and lower sides of the reactor shell 10. The high-voltage pole plate 4 connects with the reactor shell through the insulation slot 8 The body 10 is connected, the dielectric barrier layer 6 is close to the grounding plate 7 and fixed by the slot 9, and there is a gap of 15 mm between the front and rear sides of the grounding plate 7 and the dielectric barrier layer 6 and the reactor shell 10. Pass through the treated exhaust gas. The space enclosed by the two high-pressure p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com