Rotary water-cooled spray-burning type biomass particle burner

A biomass particle and burner technology, applied in the direction of solid fuel combustion, combustion method, combustion equipment, etc., can solve the problems of unsuitable burning of straw particles, easy slagging, etc., to facilitate popularization and use, and ensure continuous combustion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

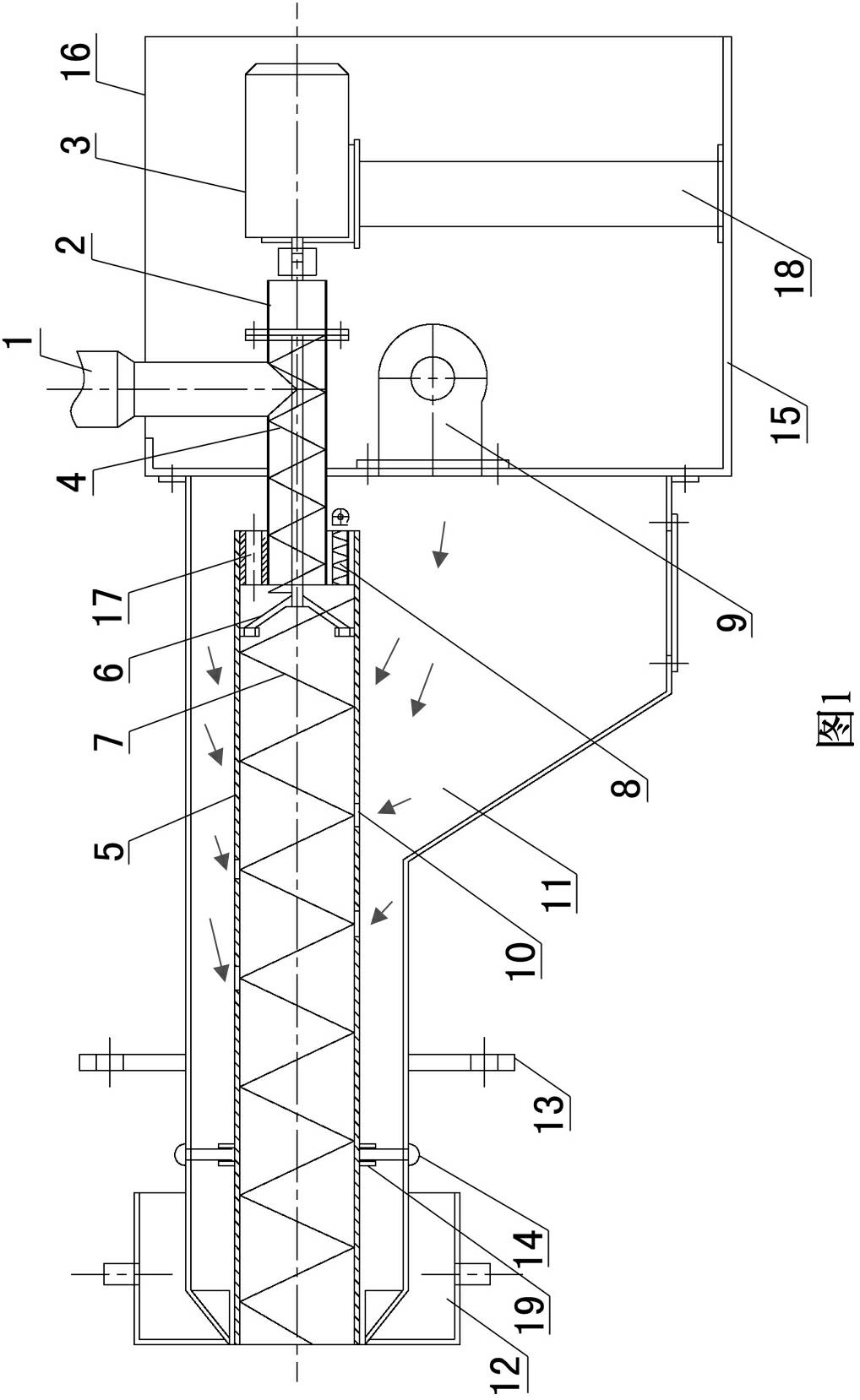

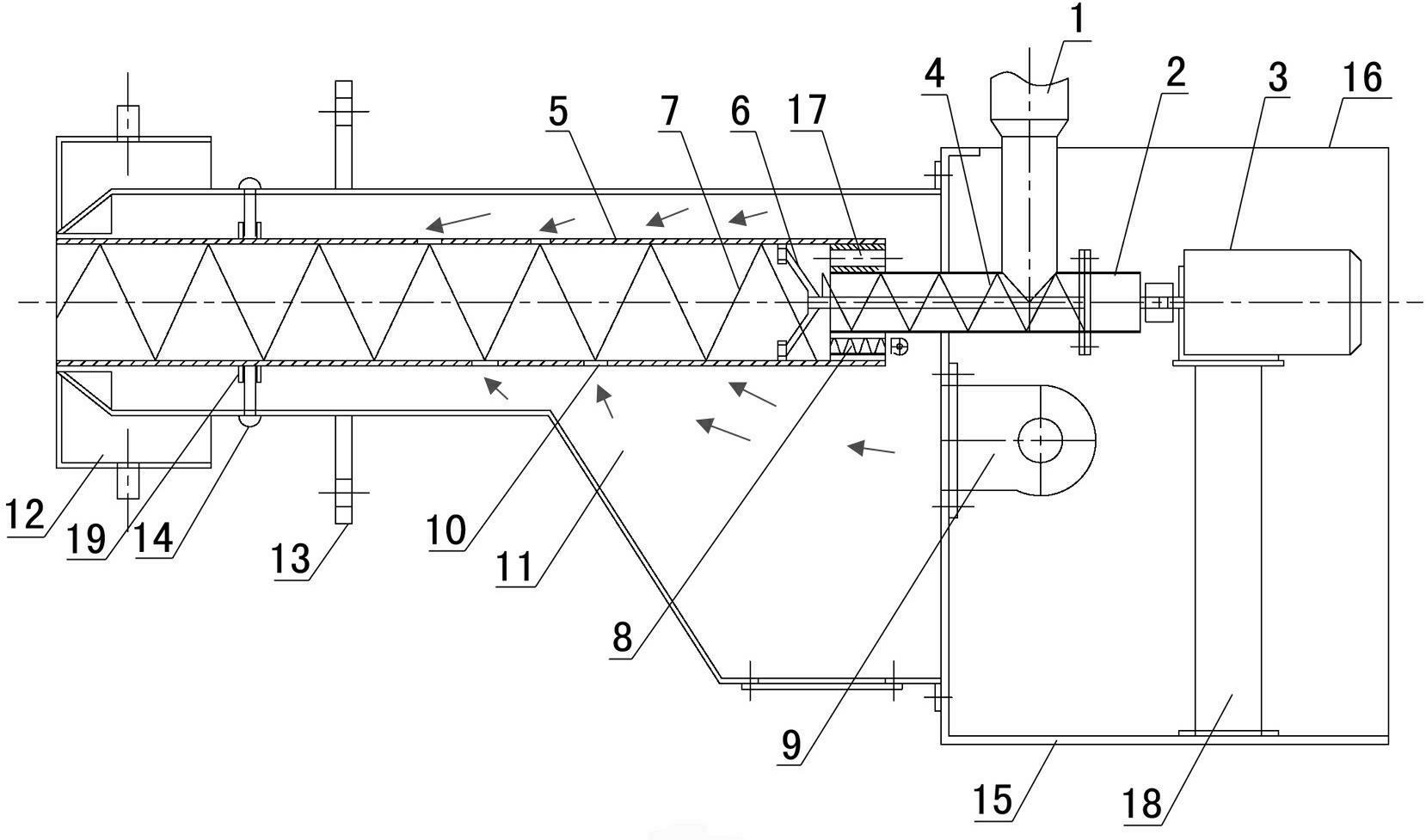

[0018] Examples see figure 1 As shown, this rotating water-cooled spray-fired biomass pellet burner includes a feed system, an air supply system and a combustion system. The feed system includes a hopper 1, a material pipe 2, an auger 4 and a speed-regulating motor 3, The air source of the air supply system is a blower 9, and it is characterized in that: the combustion system includes a horizontally arranged combustion cylinder 5 and an air chamber 11 that surrounds the periphery of the combustion cylinder 5 and covers the air outlet of the blower 9. The outer wall of the air cavity 11 is provided with a flange 13 for connecting the furnace; The air hole 10 communicated with the chamber 11, the charging port of the combustion cylinder 5 is provided with an electric ignition device 8 and a longitudinal air inlet 17 connecting the interior of the combustion cylinder 5 with the air chamber 11; One end of the feed port is concentrically fixedly socketed with the discharge end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com