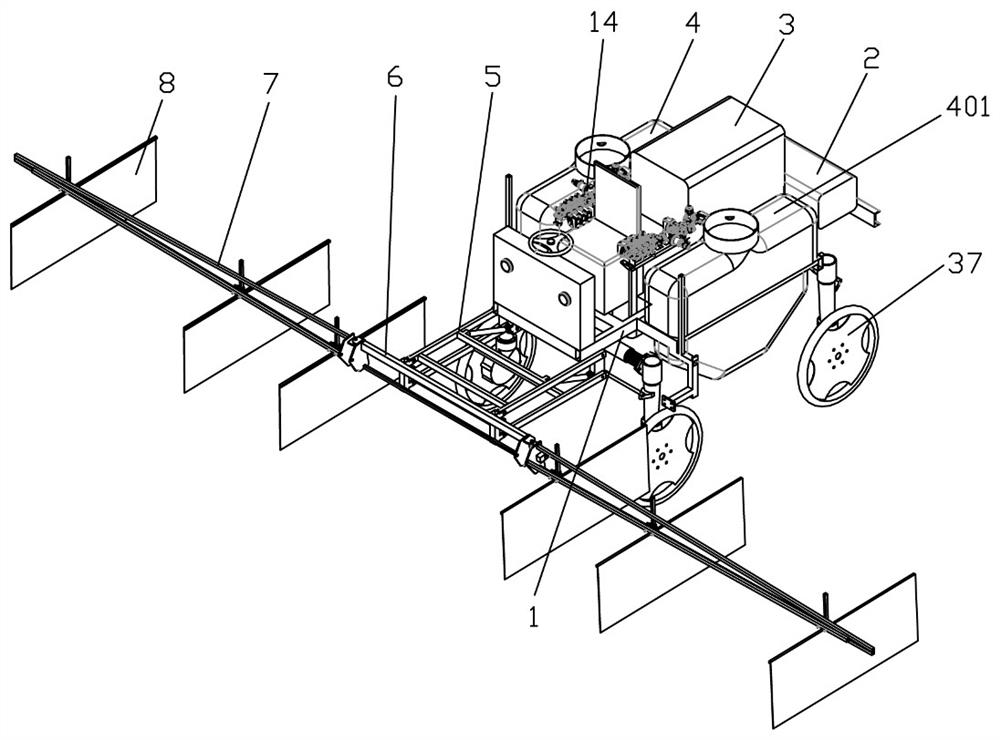

Strip-shaped composite planting high-ground-clearance zoning boom sprayer

A technology of composite planting and boom spraying, which is applied to the device for capturing or killing insects, application, animal husbandry, etc. It can solve the problems of slow walking speed of the sprayer, incomplete removal of weeds, and crop production reduction, etc., to improve spraying efficiency. Uniform distribution, improved steering performance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

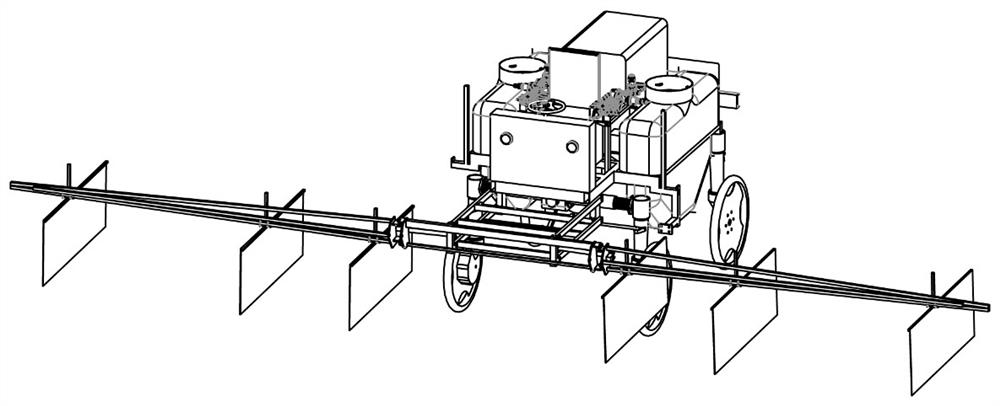

Embodiment 1

[0041] Embodiment 1, in my country's agricultural production, the intercropping planting mode of crops improves the utilization rate of land resources, makes full use of the characteristics of nutrient complementarity between crops and suppression of diseases and insect pests, and is widely promoted. Field management in agricultural production At present, chemical weeding is still the main method. Among them, the self-propelled boom sprayer with high clearance is highly efficient, easy to operate, and has the advantages of uniform spray distribution. It is recognized by the majority of growers. However, chemical herbicides for different crops There are large differences, and even serious interference with each other, resulting in phytotoxicity, which will lead to a substantial reduction in crop production, and although the high-ground self-propelled boom sprayer can chemically weed better, but the high-ground self-propelled boom sprayer sprays The uniformity of the spray is affect...

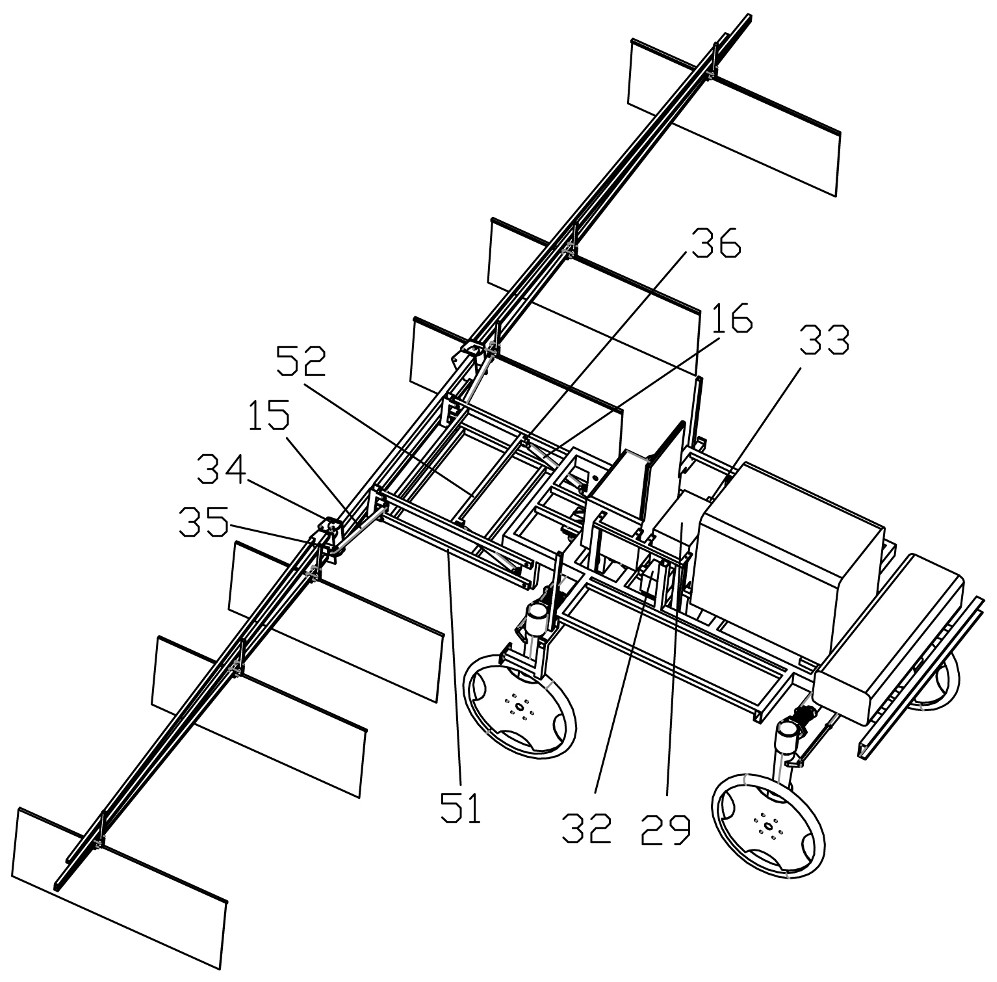

Embodiment 2

[0048] Embodiment 2, a strip-shaped compound planting high-gap partition boom sprayer in this implementation will be described centering on the differences from Embodiment 1.

[0049] In this example, if Figure 10-11 As shown, the differential gear 30 is provided with a shock absorber 31, under the effect of the shock absorber 31, it is ensured that the sprayer is more stable during field spraying operations, and when the sprayer is in a small-angle rollover state, The situation that affects the uniformity of the spray can make the sprayer perform the spraying operation more stably.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com