Indoor soft soil powder spraying solidifying device

A technology of curing device and powder spraying, which is applied in the directions of clay preparation device, clay mixing device, and raw material supply device for sale, etc., can solve the problems of poor reinforcement effect, inconvenient operation, slow stirring speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

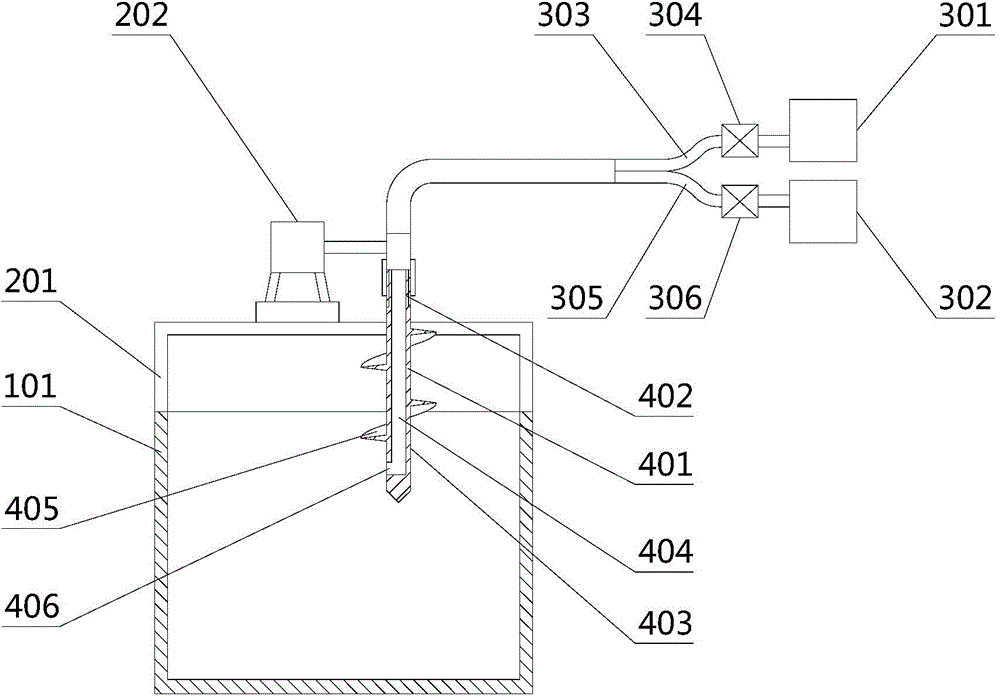

[0052] see figure 1 and figure 2 The indoor soft soil powder spray curing device provided in this embodiment includes a test box 101 with an opening at the upper end and a bracket 201 arranged above the test box 101. A stirring device is arranged on the support 201, and the stirring device is connected to the input device.

[0053] The input device includes an injection pump 301 for injecting powdery curing agent and an air compressor 302 for injecting high-pressure air. The injection pump 301 is connected with a feeding pipe 303, and the feeding pipe 303 is provided with a feeding valve 304. The air compressor 302 is connected with an air supply pipe 305, and an air supply valve 306 is arranged on the air supply pipe 305.

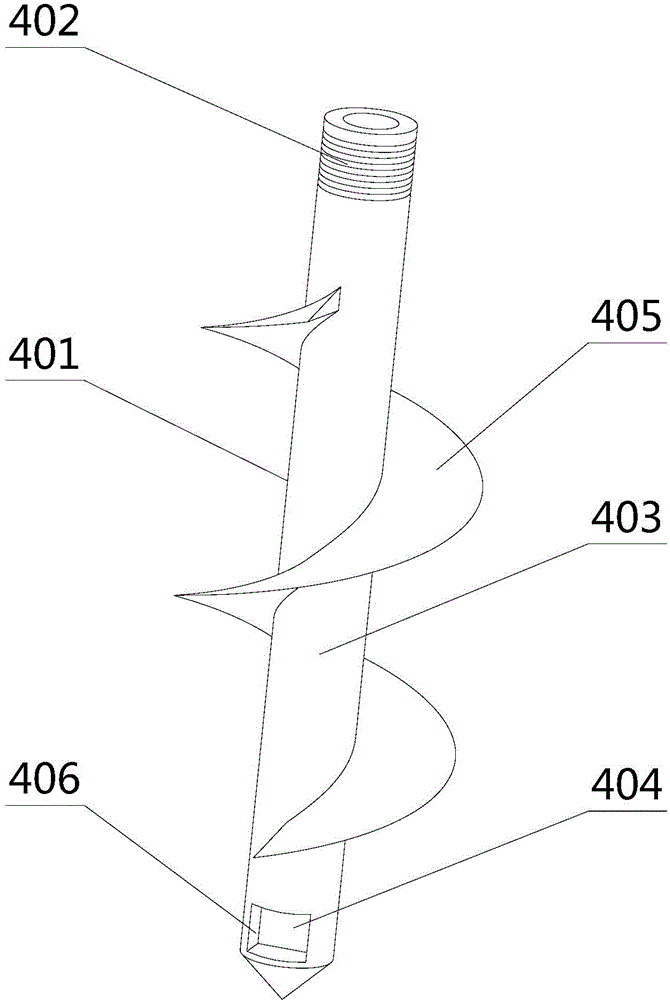

[0054] The stirring device includes a stirring shaft 401 and a motor 202 for driving the stirring shaft 401 to rotate. The stirring shaft 401 includes a rotating part 402 and a stirring part 403 , and the rotating part 402 is connected with the motor 202...

no. 2 example

[0059] The basic structure, principle and technical effect of the indoor soft soil powder spraying curing device provided by this embodiment are the same as those of the first embodiment. For a brief description, the part not mentioned in this embodiment can refer to the first embodiment corresponding content in the example.

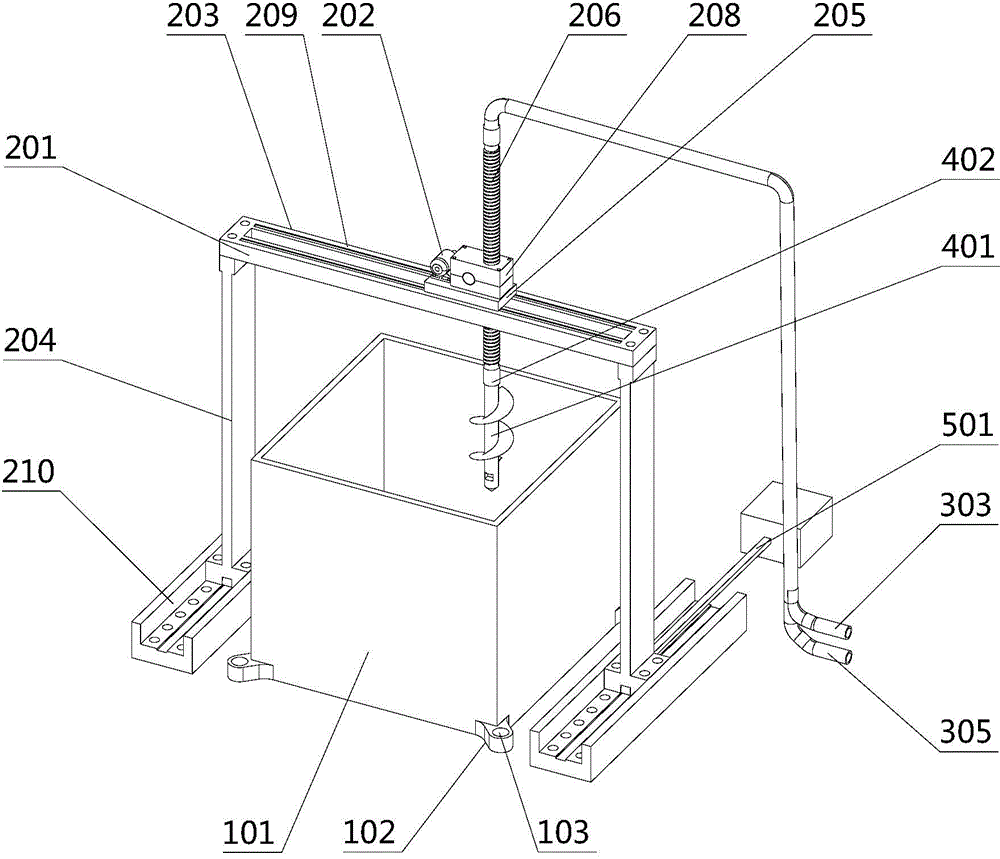

[0060] see figure 2 and image 3 , the bracket 201 includes a beam 203 and two uprights 204 , and the two ends of the beam 203 are respectively connected with the uprights 204 . The beam 203 is provided with a bearing 205, the motor 202 is arranged on the bearing 205, the motor 202 is connected with the screw rod 206 arranged vertically through the transmission mechanism, and the transmission mechanism can make the screw rod 206 rotate upward or downward along the vertical direction , the lower end of the screw rod 206 passes through the support 205 and the beam 203 , and is connected with the upper end of the rotating part 402 .

[0061] The screw r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com