Railway vehicle wheel flange lubrication dry-type continuous lubricating rod

A lubricating stick, dry technology, applied in the field of lubricants, to achieve the effect of reducing maintenance frequency, transportation cost, wear and maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

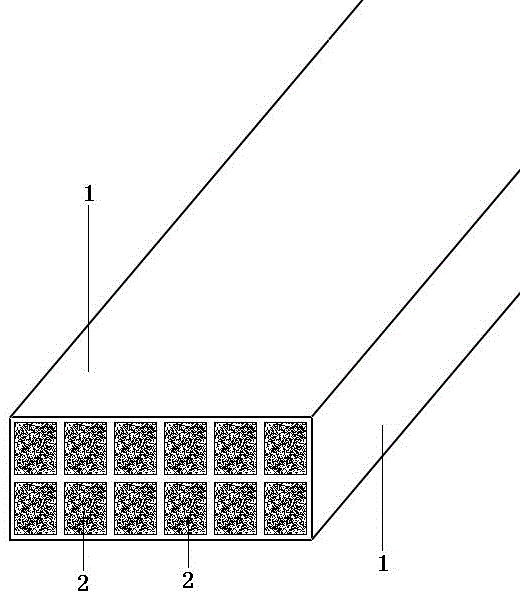

Image

Examples

Embodiment approach

[0022] A rail locomotive rim lubricating dry-type continuous lubrication rod: raw materials include 40% flake graphite powder, 8% molybdenum disulfide powder, 20% polytetrafluoroethylene particles, 8% polyethylene wax particles, ethylene-vinyl acetate grease 10% granules, 14% tin powder, after mixing and stirring, heating and granulating, making shells, filling and shaping to make dry continuous lubrication sticks;

[0023] The production method of dry continuous lubrication stick is as follows:

[0024] Flake graphite powder: take the leftovers and wastes of flake graphite originals processed by the factory and grind them into granules. In the crushing workshop enclosed by glass curtain walls, workers pour graphite particles into spherical mills through electronic control facilities outside, according to 30-40r / The speed of min is used for impact crushing, and the dust reaching more than 100 meshes is pumped from the inside of the mill to the dust recovery system by the exha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com