Application of nano-copper in cutting fluid

A cutting fluid, nano-copper technology, applied in the petroleum industry, base materials, additives, etc., can solve the problems of high dosage, high cost, and the cutting fluid cannot have anti-corrosion, anti-rust, pressure resistance, lubrication and bactericidal properties at the same time. , to achieve the effect of simplifying production steps, efficient anti-corrosion, and simplifying the formulation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Wherein, the preparation method with organic long carbon chain self-dispersing nano-copper comprises the following steps:

[0049] Step 1: Mix the copper source with water to obtain a copper source solution, place the copper source solution in a nitrogen, argon, or air atmosphere, and heat it to 40°C-75°C, preferably 50°C-65°C , further preferably at 55°C; the copper source aqueous solution is selected from any one or more of copper sulfate pentahydrate, copper chloride, copper bromide, copper acetate, copper nitrate, and copper acetylacetonate aqueous solutions.

[0050] Step 2: add reducing agent to the copper source solution after step 1 heating and react, obtain reduced copper source solution; Reducing agent is selected from hydrazine hydrate, sodium hypophosphite (NaH 2 PO 2 ), sodium borohydride, ascorbic acid (vitamin C) and sodium ascorbate in any one or more.

[0051] Step 3: Mix the dialkyl dithiophosphoric acid coating agent with an organic solvent to obtai...

Embodiment 1

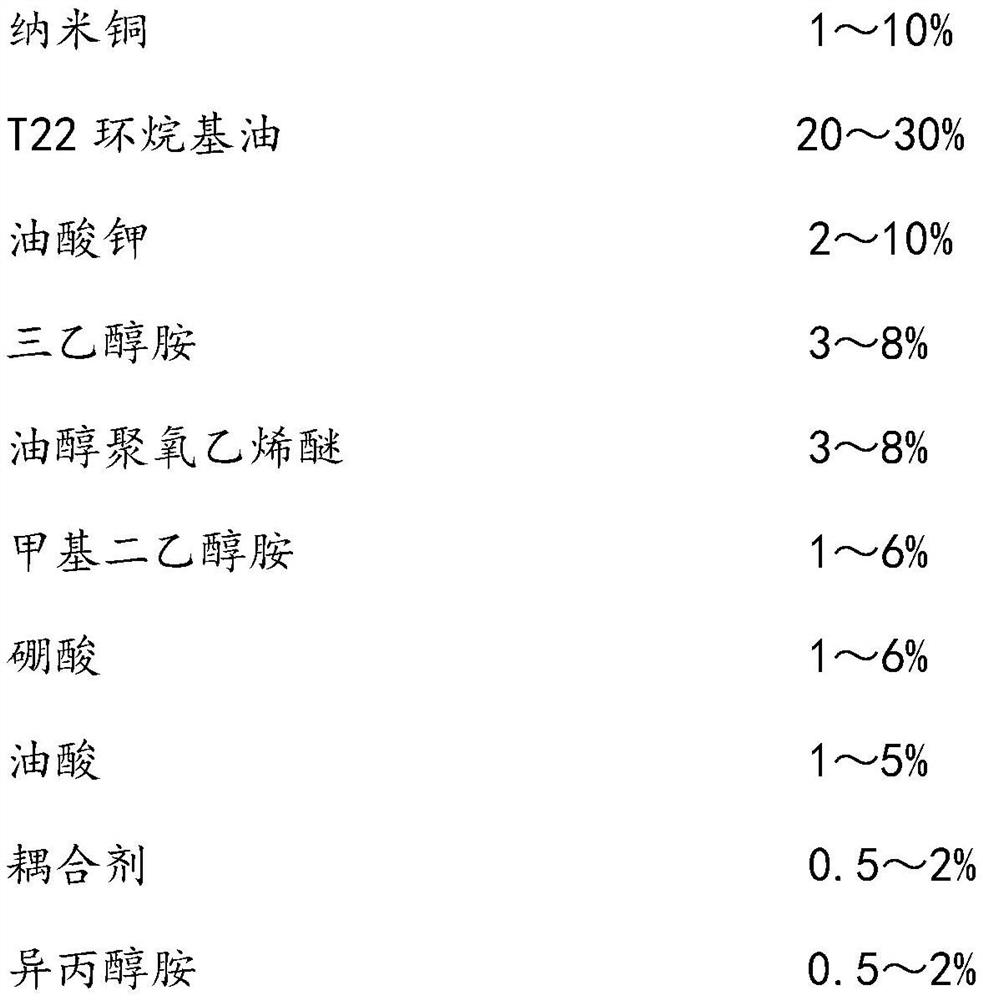

[0064] This embodiment is a water-based aluminum alloy semi-synthetic cutting fluid, comprising the following components in mass percentage:

[0065]

[0066] Wherein, the preparation method of self-dispersing nano-copper with organic long carbon chains in this embodiment is as follows:

[0067] First prepare the HDDP coating agent: add carbon-based alcohol compounds and phosphorus pentasulfide in a 250mL single-necked flask, put a stopper on the bottle mouth of the single-necked flask, and connect the air guide tube, heat the reaction mixture to 80 ° C under stirring conditions, and Insulate for 3 hours, and the hydrogen sulfide gas released by the reaction is passed into the copper sulfate aqueous solution through the air duct. After the reaction is completed, the residual solid in the reaction system is removed to obtain a transparent light yellow liquid, which is the dialkyl dithiophosphoric acid coating agent. In this embodiment, the hydrogen sulfide gas produced by t...

Embodiment 2

[0089] This embodiment is a kind of water-based magnesium alloy semi-synthetic cutting fluid, including the following components in mass percentage:

[0090]

[0091]

[0092] In this embodiment, the preparation method of nano-copper with organic long carbon chain self-dispersion is consistent with that in Example 1, the differences are as follows:

[0093] In step 1, the carbon-based alcohol compound is a mixture of n-dodecyl alcohol of 65% by mole percent, isooctyl alcohol of 20% by mole percent, and ethanol of 15% by mole percent, with a total mass of 53.9g ( 350mmol), the consumption of phosphorus pentasulfide is 22.2g (100mmol), the mol ratio of mixed alcohol and phosphorus pentasulfide is 3.5:1, step 1 finally obtains dialkyl dithiophosphoric acid mixture.

[0094] In step 2, the copper source is copper sulfate pentahydrate, and the consumption is 37.4g (150mmol), and the water for dissolving copper sulfate pentahydrate is 200mL, and the reducing agent is 80% hydra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com