Vibration auxiliary rotation cutting device based on acute angle straight plate type flexible hinge

A technology of flexible hinges and flexible devices, which is applied in feeding devices, metal processing machinery parts, metal processing equipment, etc., can solve the problems that the residual height of the tool cannot be eliminated and the difficulty of control is increased, so as to eliminate the residual height, facilitate heat dissipation, reduce effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

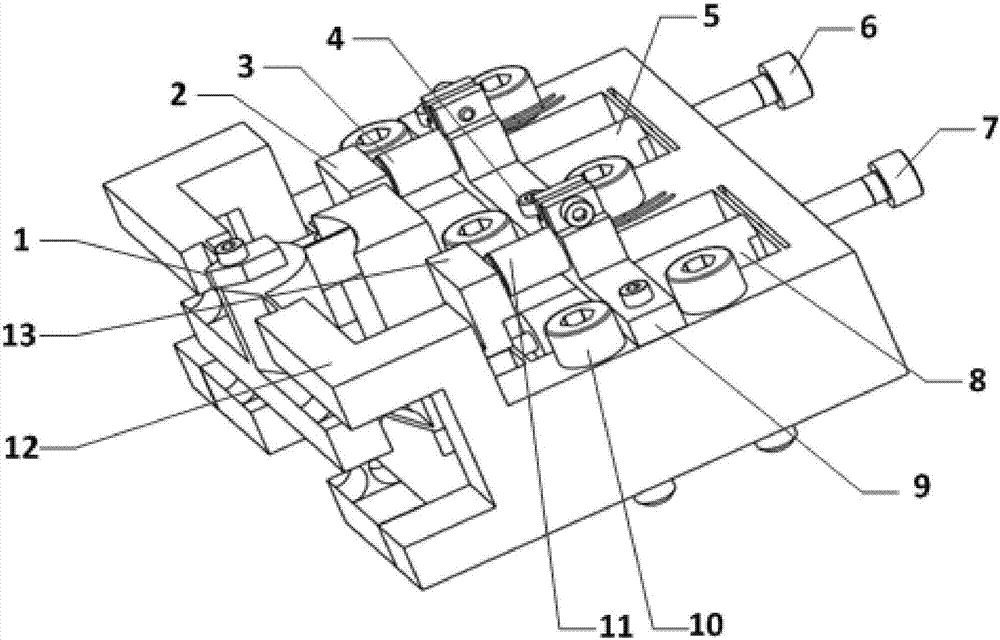

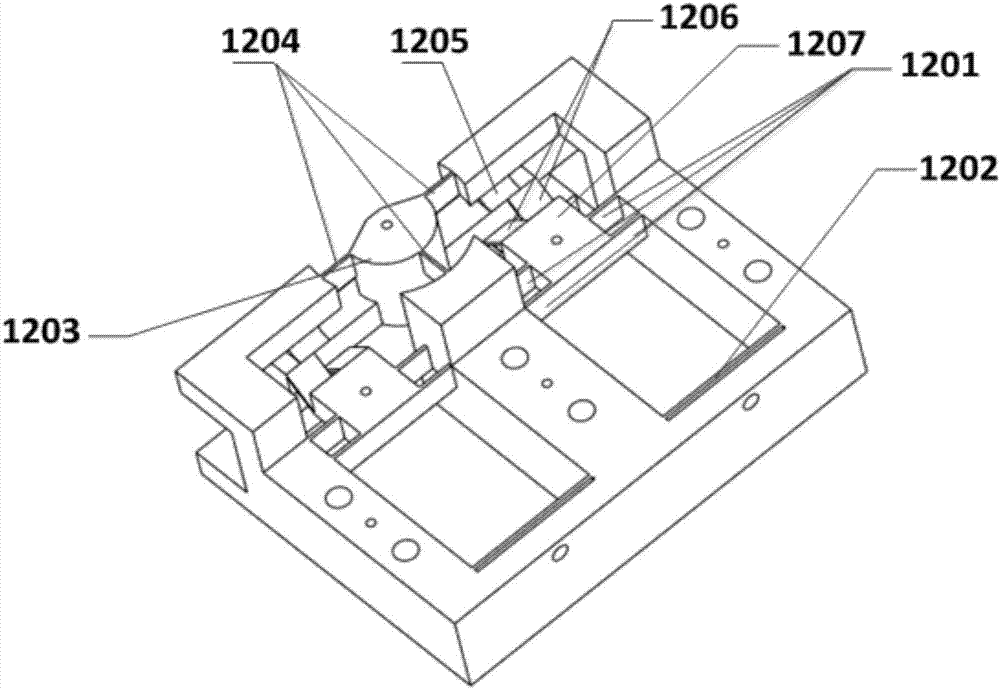

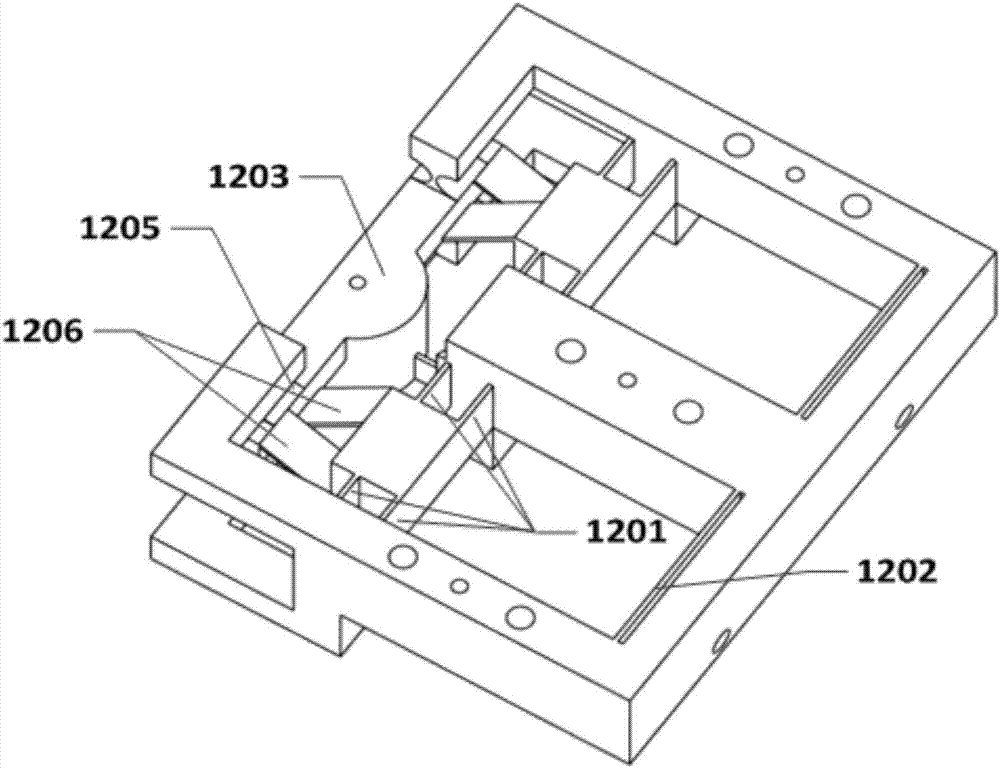

[0020] Install piezoelectric stack 1 5 and piezoelectric stack 2 8 on the flexible device platform 12 with pre-tightening screw 1 6 and pre-tightening screw 2 7 respectively, capacitive displacement measurement baffle 1 2 and capacitive displacement measurement baffle Two 13 are respectively connected with the flexible device platform 12 by fastening screws 4, and capacitive displacement sensor one 3 and capacitive displacement sensor two 11 are respectively installed on the capacitive displacement sensor holder 9 by fastening screws 4, and the capacitive displacement sensor clip The seat 9 is installed on the flexible device platform 12 through the fastening screws 4 , the diamond tool 1 is fixedly connected with the flexible hinge platform 12 through the fastening screws, and the flexible hinge platform 12 is connected with the installation base through the fastening screws 10 .

[0021] The flexible device platform 12 of the present invention belongs to the left-right symmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com