Solid lubricating device used for open-type lead screw nut transmission of numerical control machine tool

A CNC machine tool, solid lubrication technology, applied in transmission parts, gear lubrication/cooling, mechanical equipment, etc., can solve the problems affecting the positioning accuracy of the roller table, achieve efficient lubrication effect, reduce friction and wear, and reduce steel grit erosion degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

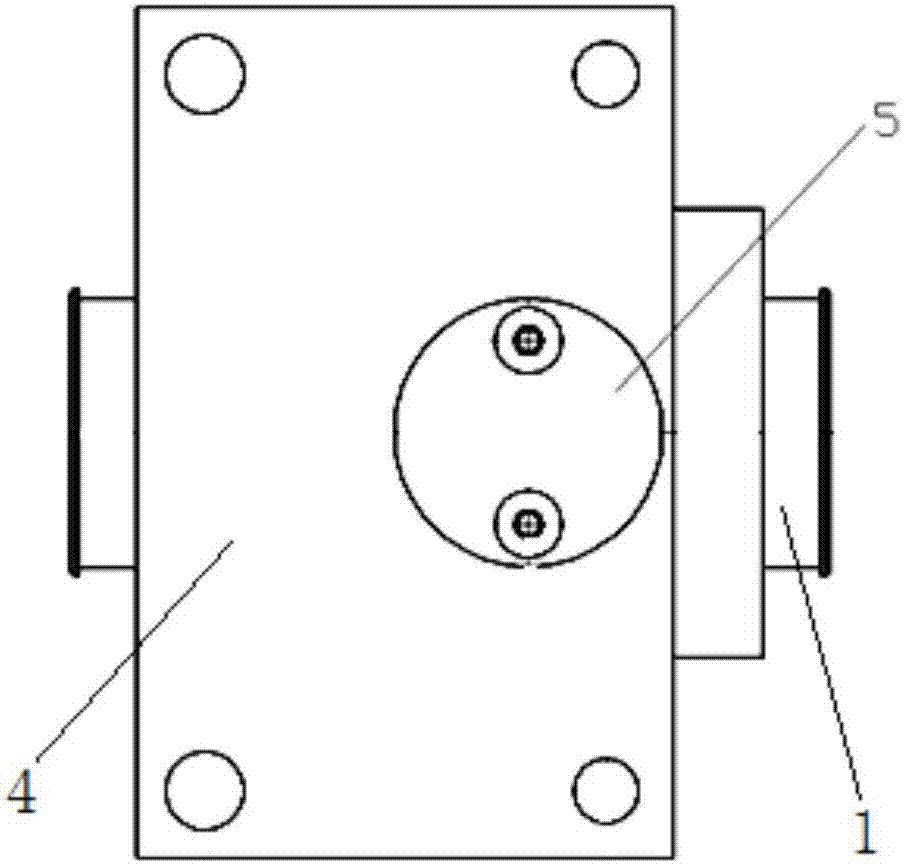

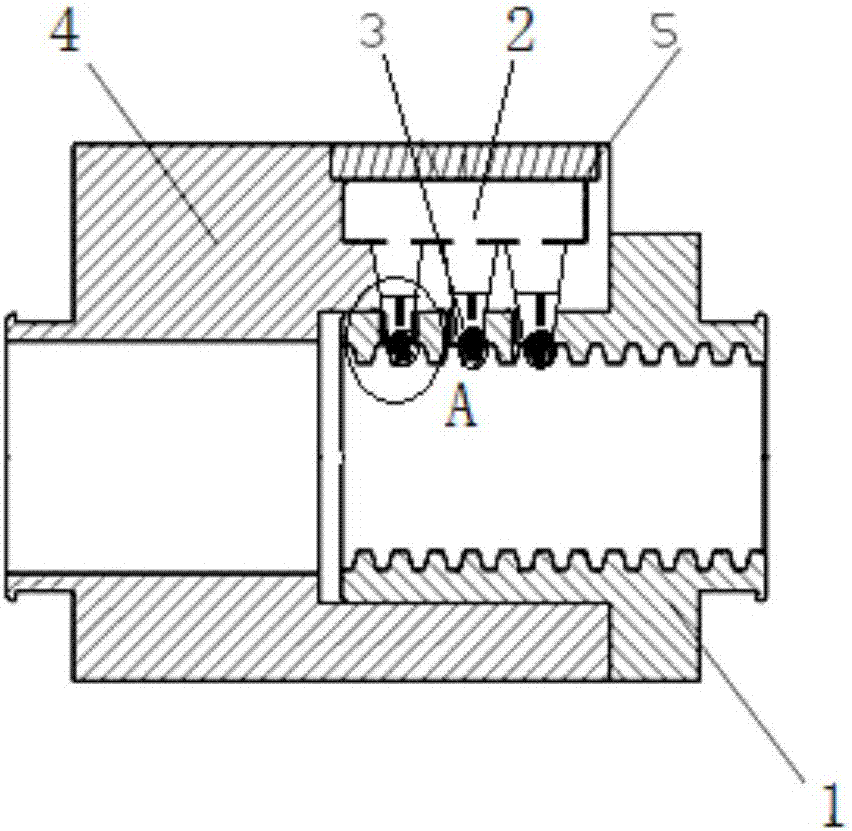

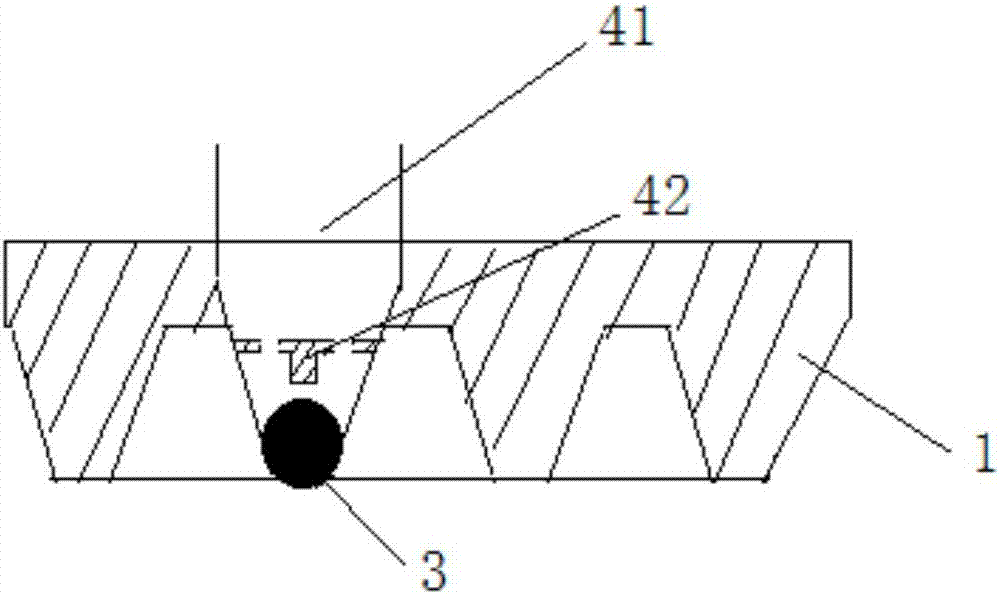

[0023] A solid lubricating device for open screw nut transmission of CNC machine tools, its structure is as follows Figure 1~3 As shown, the device is used for surface lubrication of open screw rods, including a nut 1 and a nut seat 4, the nut 1 is fixed on the inside of the nut seat 4, and the connection between the interior of the nut seat 4 and the nut 1 is provided for placing a solid lubricant The hollow inner cavity 2 of the nut 1 communicates with the inner cavity of the nut 1 through the powder passage 41 . Wherein, the local enlargement figure of powder passage 41 is as follows: image 3 As shown, the powder channel 41 is set at the tooth root of the nut 1. The front end of the powder channel 41 is funnel-shaped, and a circular ball 3 is stuck at the port of the powder channel 41. The push rod 42 used to prevent the round ball 3 from falling back. The nut seat 4 is provided with a gland 5 for sealing the hollow cavity 2, and the gland 5 and the nut seat 4 are conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com