Crankshaft lubricating structure

A technology for lubricating structures and crankshafts, which is applied to crankshafts, liquid variable displacement machines, variable displacement pump components, etc. It can solve the problems of crankshaft climbing oil storage capacity, easy wear and lock of the frame, etc., to reduce wear and lock Die, improve lubricating performance, improve the effect of oil storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

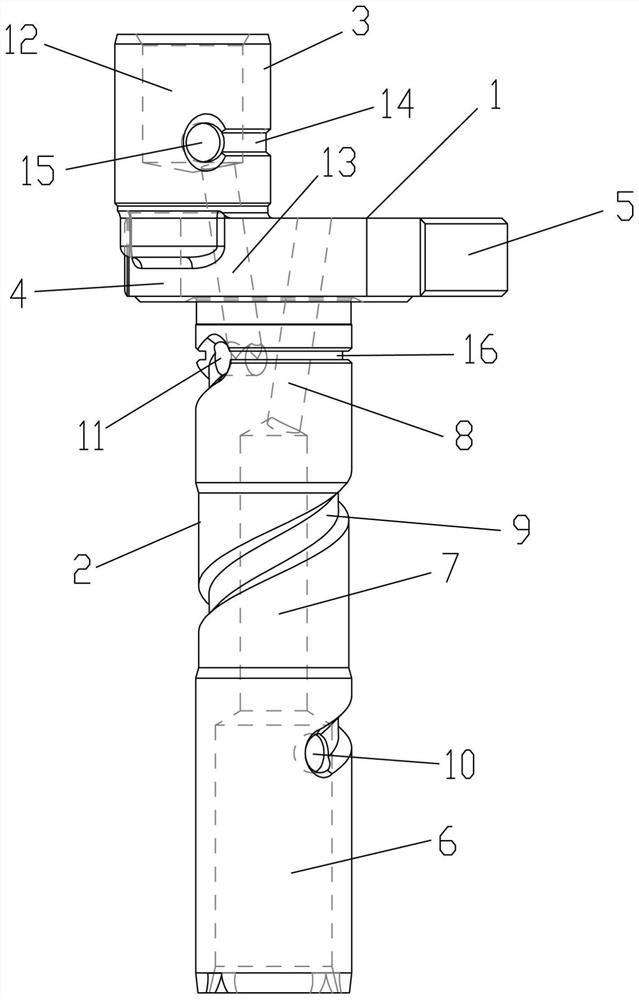

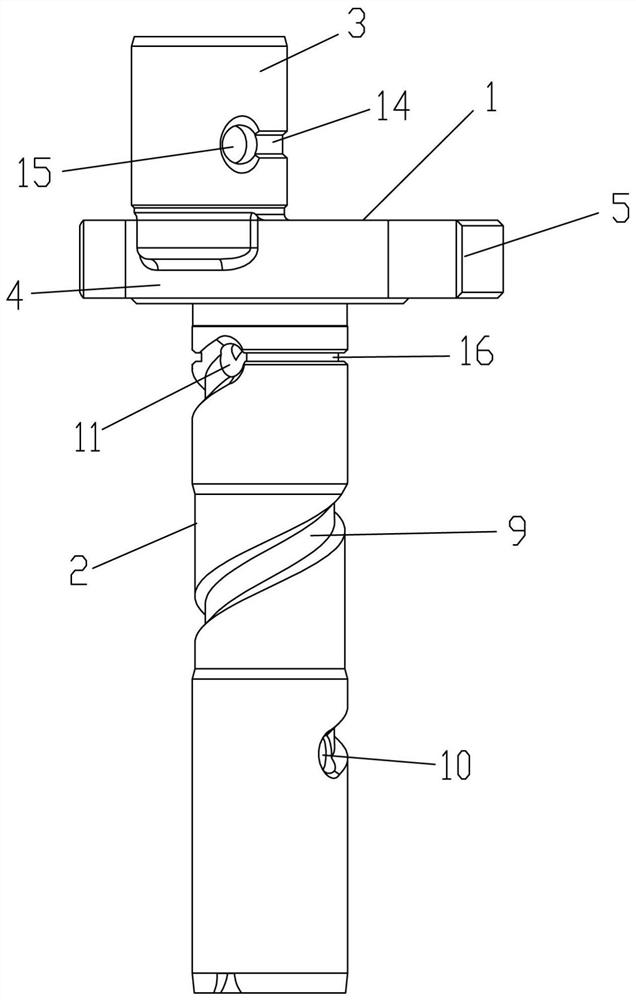

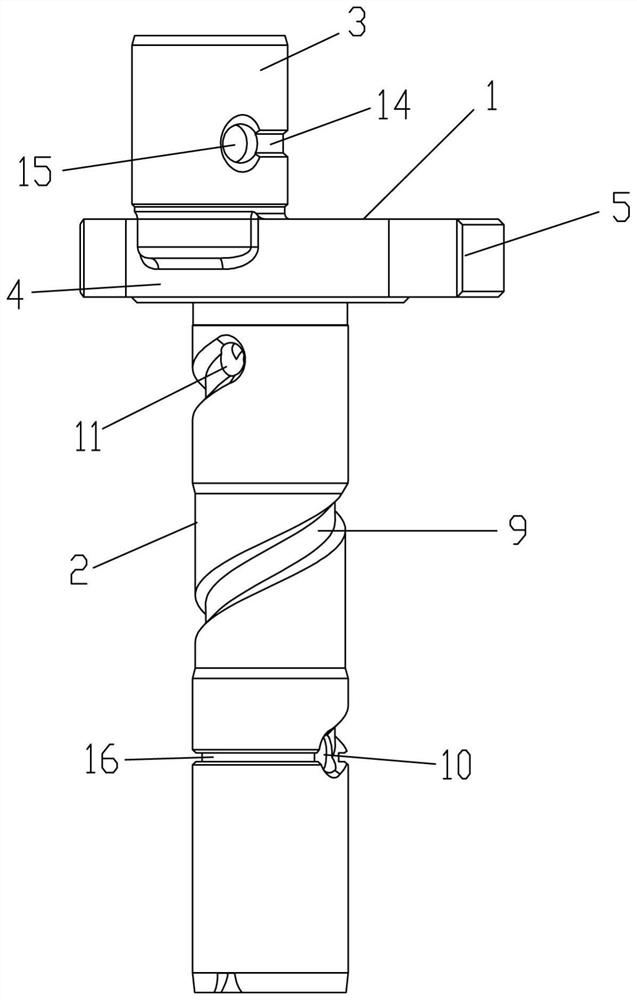

[0018] Embodiment: a kind of crankshaft lubricating structure, as Figure 1-Figure 6 As shown, it includes a crankshaft main body, the crankshaft main body includes a crankshaft major axis, an eccentric minor axis and an eccentric shaft, one side of the eccentric shaft is provided with a semicircular eccentric wheel, and the eccentric minor axis is arranged on a side away from the semicircular eccentric wheel The upper end of the eccentric shaft, the long axis of the crankshaft is arranged at the lower end of the center of the eccentric shaft, the inner side of the lower end of the long axis of the crankshaft is provided with a first channel, and the inner side of the middle end of the long axis of the crankshaft is provided with a second channel, The inner side of the upper end of the major axis of the crankshaft is provided with a third channel, the first channel communicates with the second channel, the second channel is the same as the third channel, and the lower side of t...

Embodiment approach

[0023] When the main body of the crankshaft rotates, due to the friction between the lubricating oil and the main body of the crankshaft, the lubricating oil moves upward through the first passage, and the lubricating oil flows through the first through hole to the spiral groove. When on the outer wall of the major axis, or when the ring oil groove is located outside the second through hole and on the outer wall of the major axis of the crankshaft, or when the ring oil groove is located outside the first through hole and on the outer wall of the major axis of the crankshaft and the outside of the second through hole and on the outer wall of the long axis of the crankshaft, the ring oil groove can improve the climbing oil storage capacity of the crankshaft, so that the lubricating oil can efficiently lubricate the crankshaft main body through the spiral groove, and improve the connection between the crankshaft main body and the engine. The lubricating performance between the rac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com