Speed Changer

A technology of transmission and speed change gear, applied in transmission parts, elements with teeth, belts/chains/gears, etc., can solve the problem of increased stirring resistance of electric motors, and achieve the effect of efficient lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

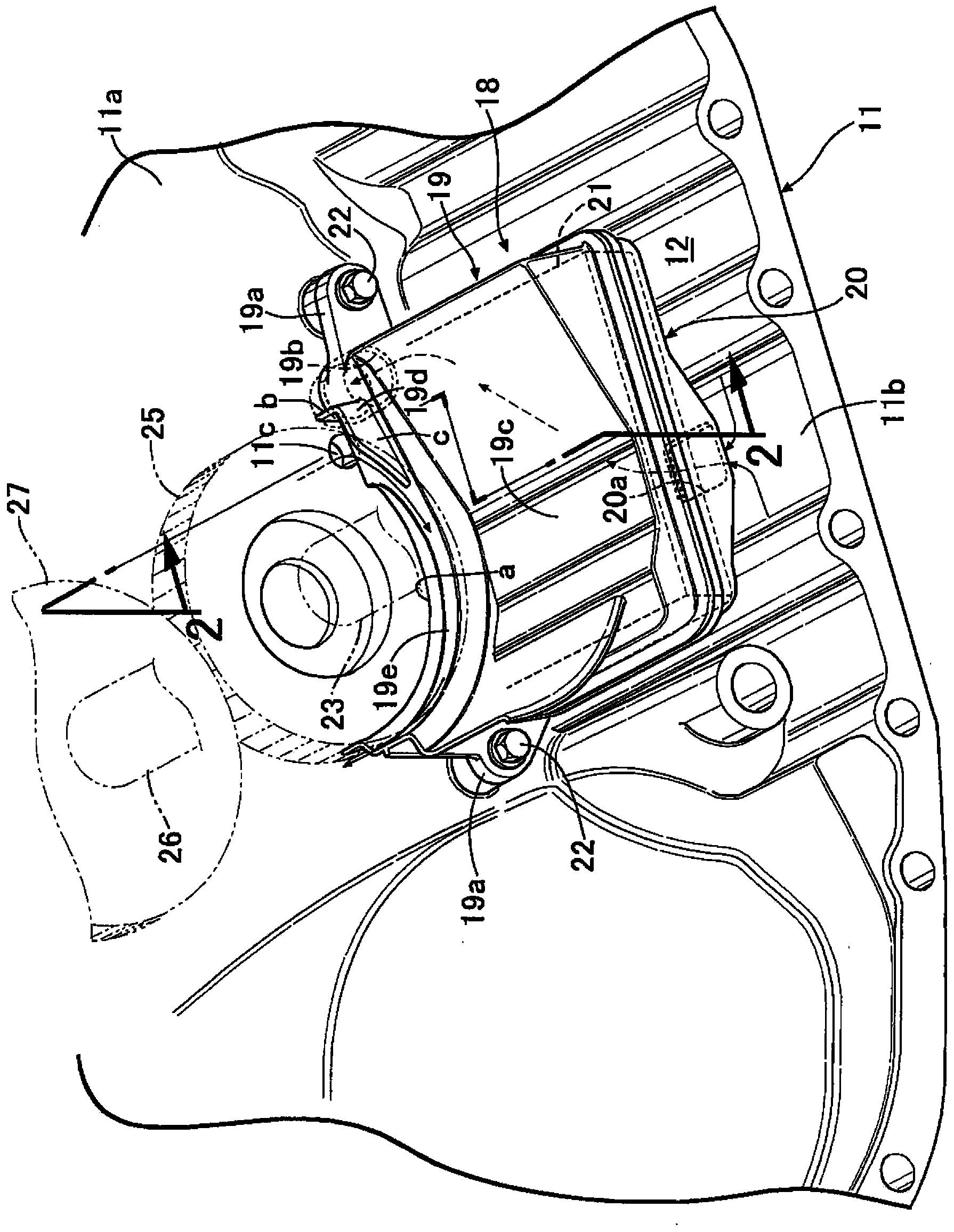

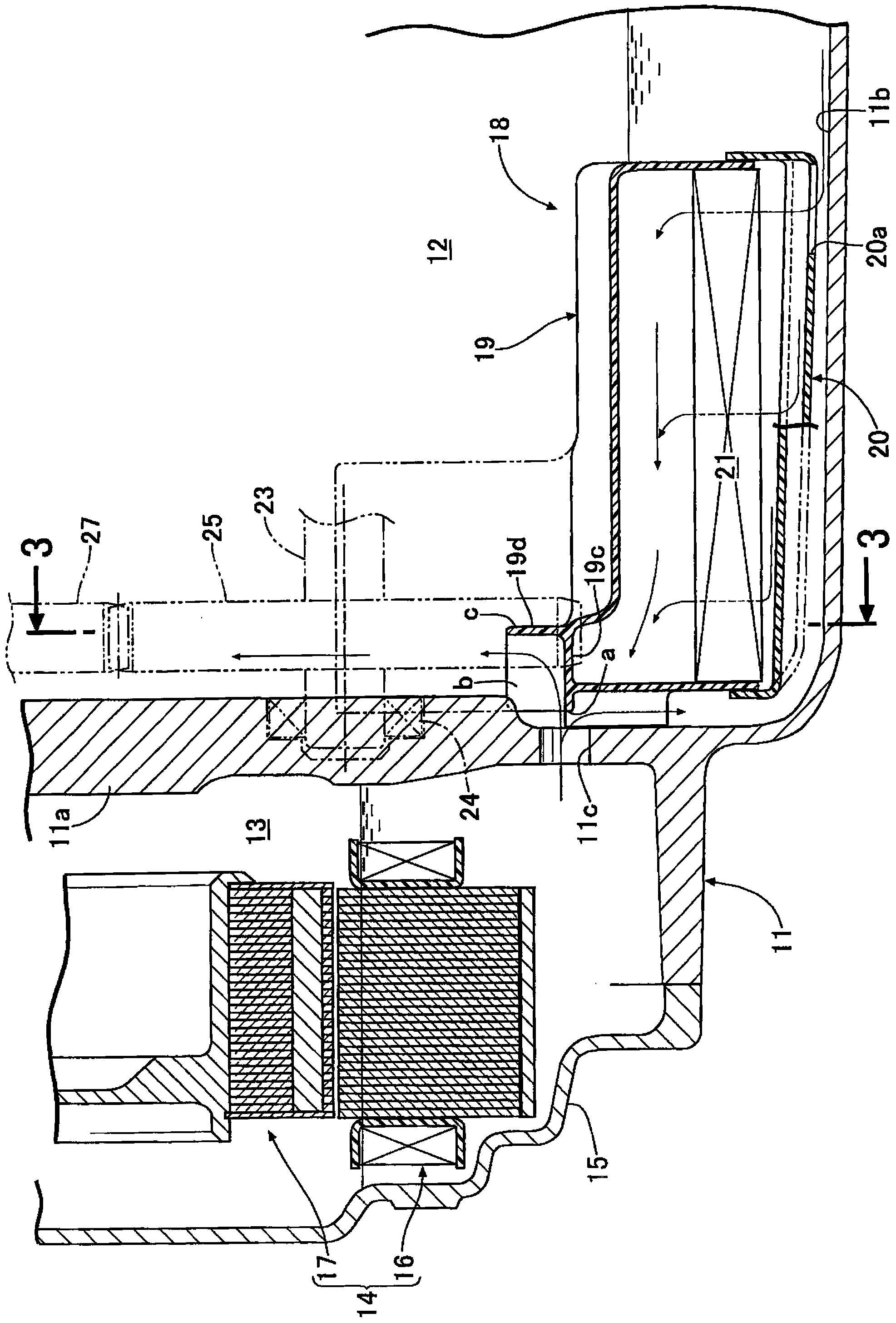

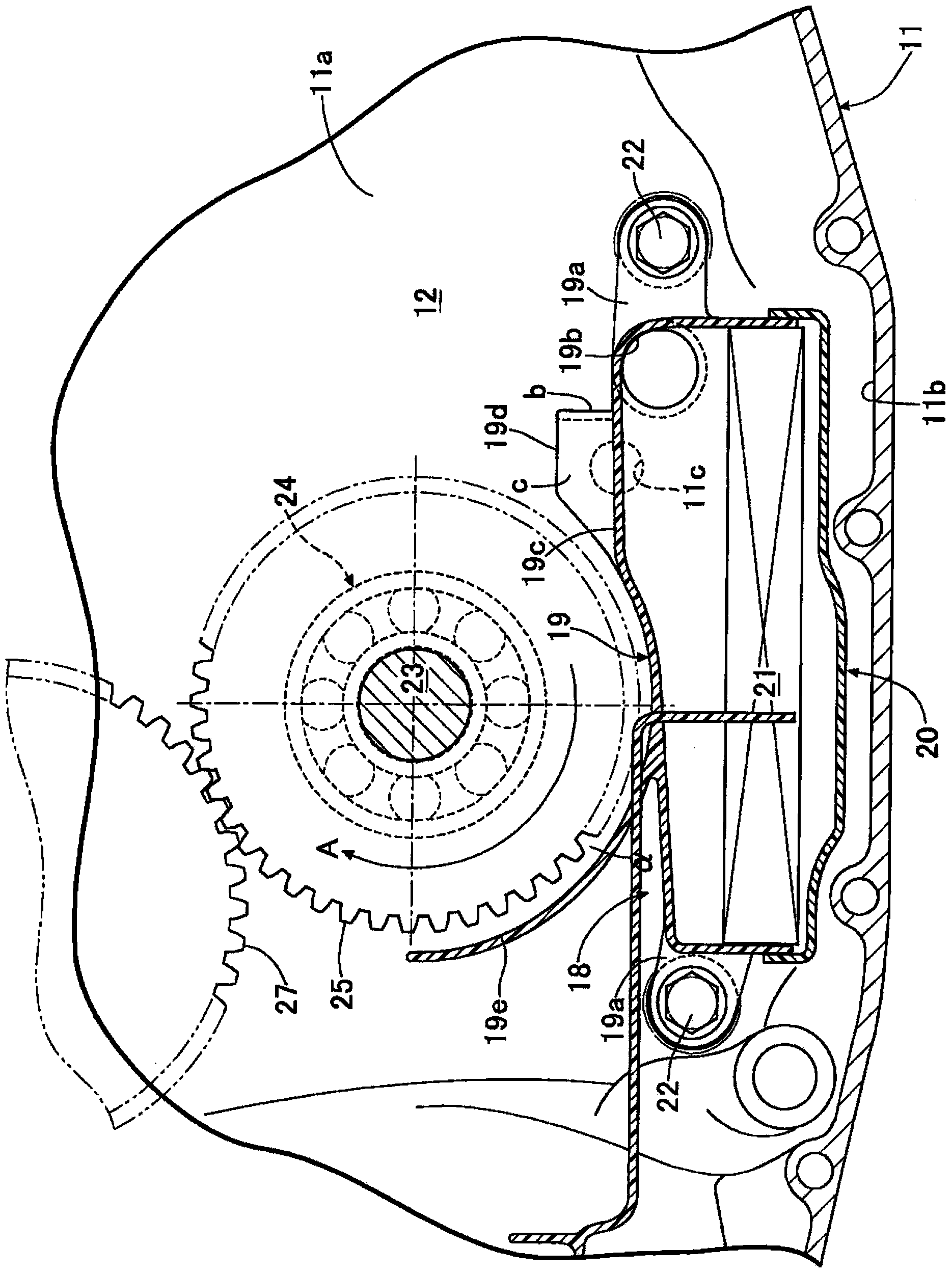

[0022] Below, according to Figure 1 ~ Figure 3 Embodiments of the present invention will be described.

[0023] The housing 11 of the transmission of a hybrid vehicle is partitioned into a first space 12 and a second space 13 by means of a partition wall 11a arranged in a vertical plane (refer to figure 2 ), the first space 12 housing the transmission shaft and the transmission gear is closed by the clutch housing (not shown), and the second space 13 housing the motor 14 is closed by the cover 15 . The motor 14 has a ring-shaped stator 16 fixed so as not to rotate, and a rotor 17 rotatably arranged inside the stator 16 .

[0024] An oil storage portion 11b for storing transmission oil is formed at the bottom of the first space 12, and an oil filter 18 is arranged in the oil storage portion 11b. The oil pumped up from the oil reservoir 11b via the oil filter 18 by an oil pump not shown is supplied to the parts to be lubricated in the first space 12 of the transmission and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com