N-shaped arranged speed reducer shell for new energy vehicle

A technology for reducer housings and new energy vehicles. It is applied to transmission parts, components with teeth, and transmission boxes. It can solve problems such as poor lubrication of the internal gears and bearings of the reducer, and achieve weak impact resistance and ensure comfort. Sexual and efficient lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

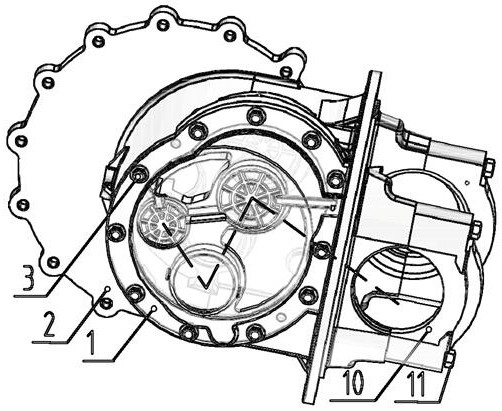

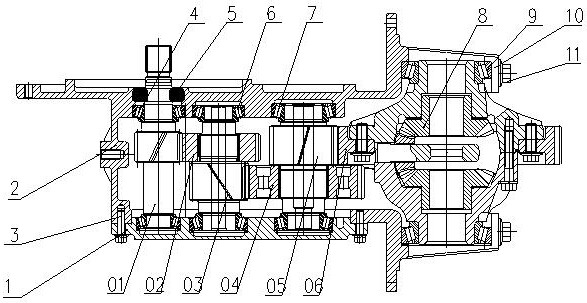

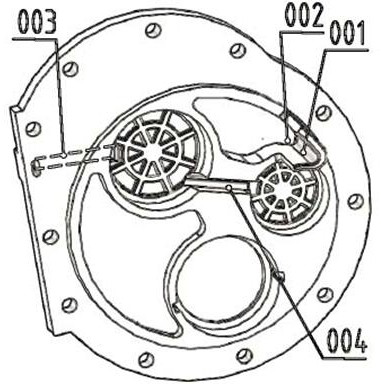

[0042] Such as figure 1 , 2 As shown in the figure, an N-shaped layout of the new energy vehicle reducer housing includes a shell cover 1 and a shell 2 connected to each other. Both the shell cover 1 and the shell 2 are provided with three-axis bearing holes, two-axis bearing holes and a Shaft bearing holes, one side of the housing 2 is equipped with a differential assembly 8, the differential assembly 8 has a differential bearing hole, and the differential assembly 8 is provided with a differential bearing 9, a bearing Cover 10, bearing cover bolt 11;

[0043] The connection line between the differential bearing hole and the three-axis bearing hole, the second-axis bearing hole, and the first-axis bearing hole on the housing cover 1 forms an "N"-shaped structure from a side view; the differential bearing hole and the housing 2 The line connecting the center of the three-axis bearing hole, the second-axis bearing hole, and the first-axis bearing hole forms an "N"-shaped stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com