Preparation and application methods of high-temperature-resistant lubricant for drilling fluid

A drilling fluid, high temperature resistant technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as reduction of common lubricants, inability to meet the lubrication requirements of drill bit bearings and drilling tools, loss of lubrication effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Under stirring, sequentially add 100 parts of waste animal and vegetable oils, 8 parts of triethanolamine and 2 parts of concentrated sulfuric acid to the reactor, and react at 120°C for 3 hours;

[0020] 2) Cool the reacted product to 60°C, add 20 parts of fatty acid methyl ester and 50 parts of white oil to the reaction kettle that continues to stir, and stir for 1 hour;

[0021] 3) Add 3 parts of molybdenum disulfide to the stirring reactor and stir for 1h;

[0022] 4) Cool to normal temperature to prepare the high temperature resistant lubricant for drilling fluid.

Embodiment 2

[0024] 1) Under stirring, sequentially add 120 parts of waste animal and vegetable oils, 12 parts of triethanolamine and 5 parts of concentrated sulfuric acid to the reaction kettle, and react at 140°C for 3 hours;

[0025] 2) Cool the reacted product to 80°C, add 50 parts of fatty acid methyl ester and 50 parts of white oil to the continuously stirred reactor, and stir for 2 hours;

[0026] 3) Add 10 parts of molybdenum disulfide to the stirring reactor and stir for 3h;

[0027] 4) Cool to normal temperature to prepare the high temperature resistant lubricant for drilling fluid.

Embodiment 3

[0029] 1) Under stirring, sequentially add 110 parts of waste animal and vegetable oils, 10 parts of triethanolamine and 3 parts of concentrated sulfuric acid to the reactor, and react at 125°C for 4 hours;

[0030] 2) Cool the reacted product to 70°C, add 50 parts of fatty acid methyl ester and 20 parts of white oil to the continuously stirred reactor, and stir for 2h;

[0031] 3) Add 5 parts of molybdenum disulfide to the stirring reactor and stir for 2h;

[0032] 4) Cool to normal temperature to prepare the high temperature resistant lubricant for drilling fluid.

[0033] The method of using the anti-high temperature lubricant for drilling fluid prepared by the method of the present invention is as follows: adding 0.5-3% of the lubricant based on the volume of the drilling fluid to the formulated density of 1.8-2.0 g / cm 3 In the drilling fluid, high-speed stirring for 30 minutes is enough.

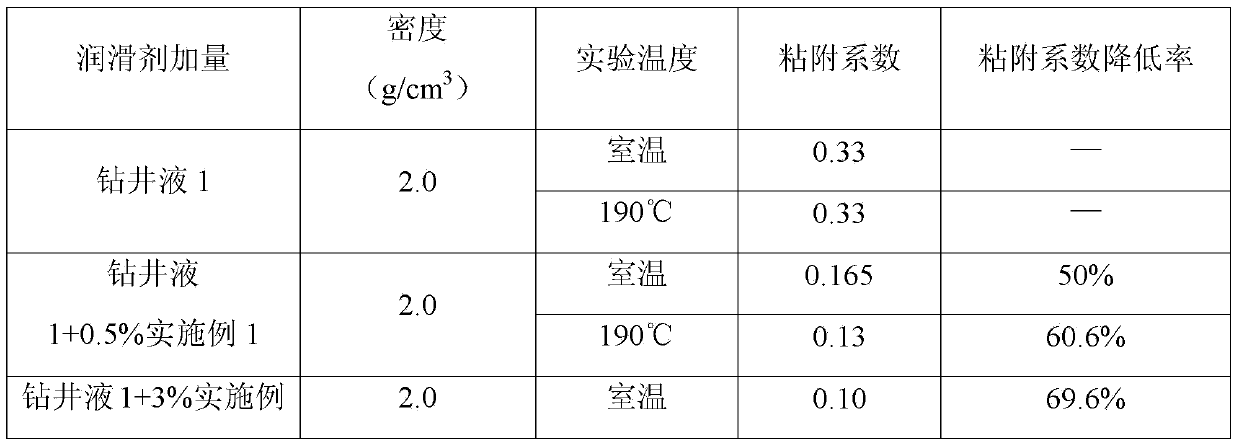

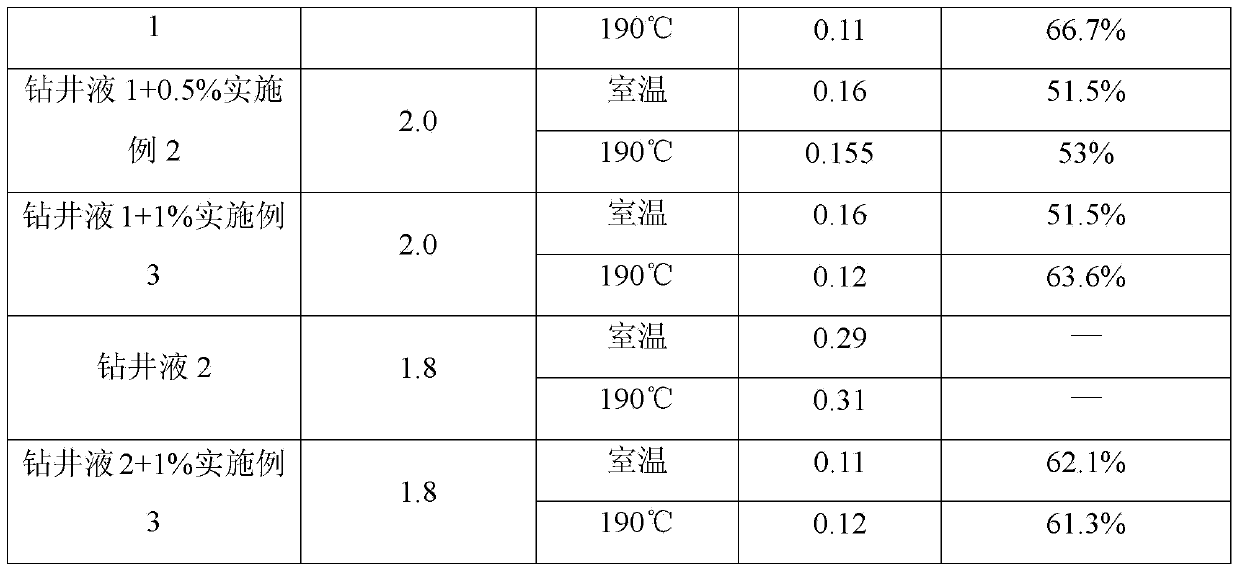

[0034] The lubricants prepared in the above 3 examples were added to drilling fluids of diffe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com