Crane walking wheel open gear lubrication system and crane including the same

A lubrication system and wheel-opening technology, which is applied in gear lubrication/cooling, belt/chain/gear, mechanical equipment, etc., can solve problems such as time-consuming, labor-intensive, grease-consuming, poor lubrication effect, etc., and achieve convenient maintenance and refueling volume Precise, simple and lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

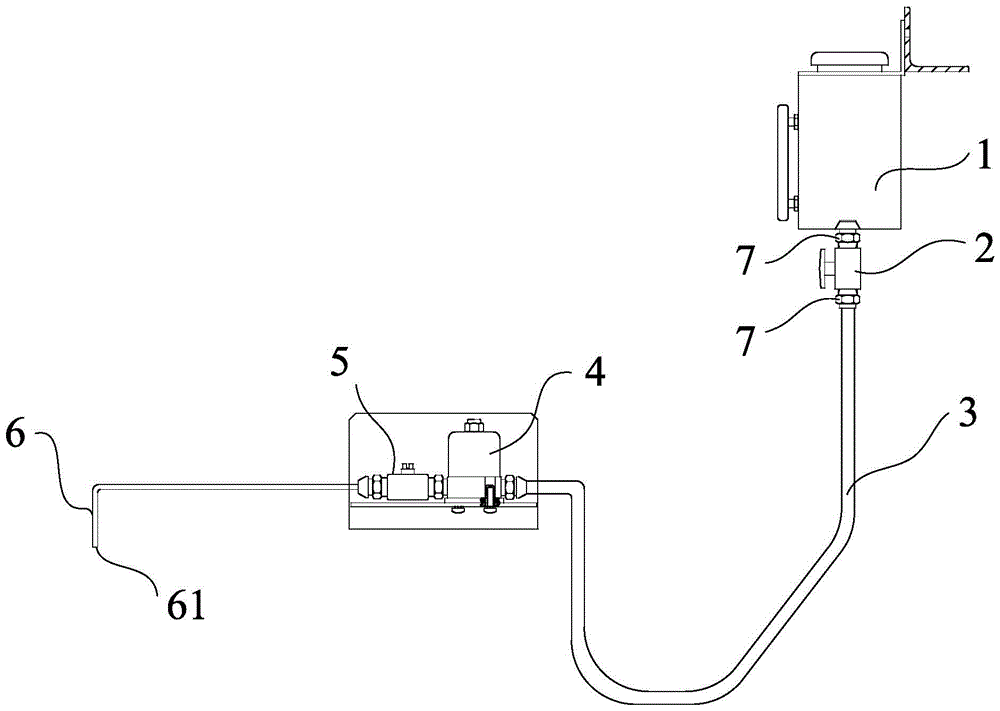

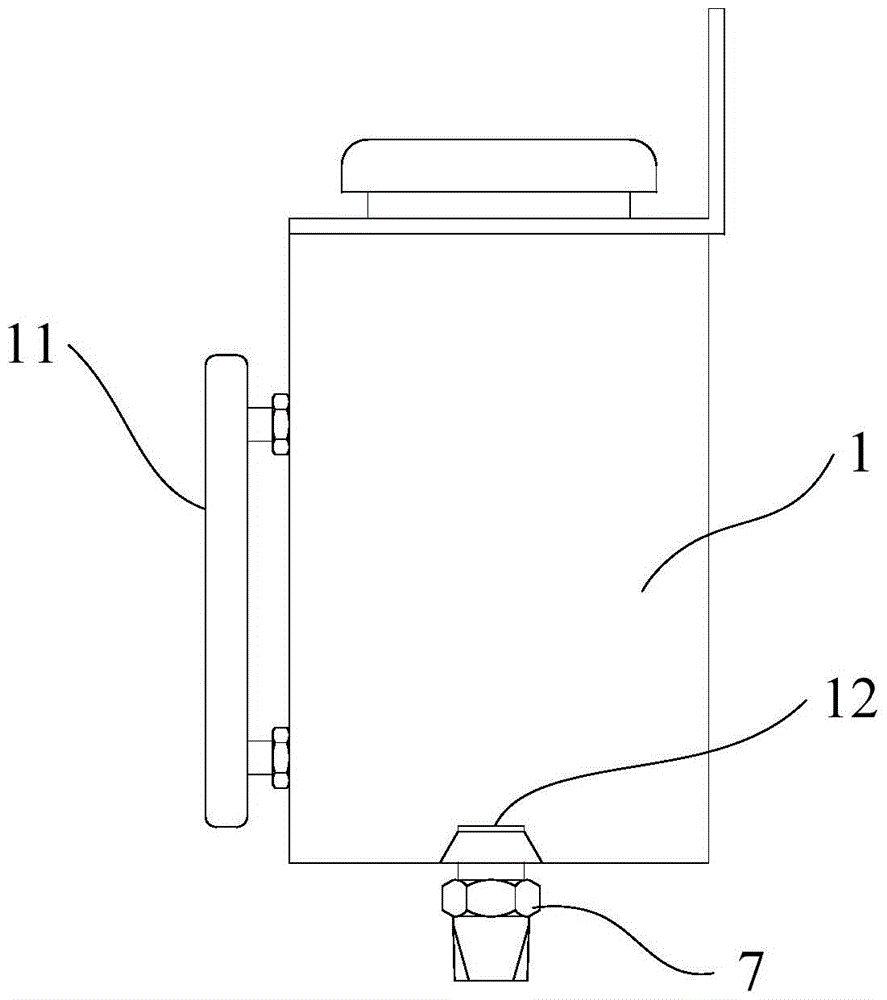

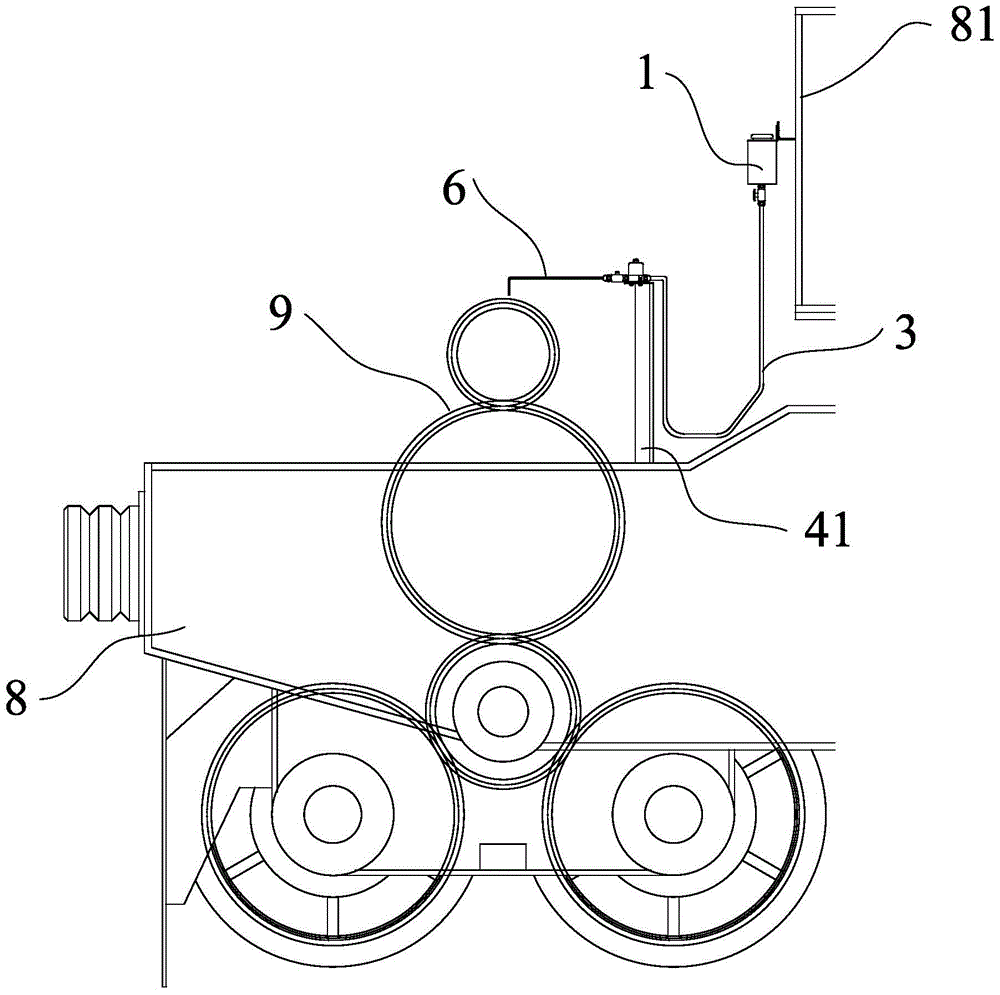

[0020] The main components of the crane walking wheel open gear lubrication system of the present invention are: fuel tank 1, oil circuit switch, oil pipe 3, solenoid valve 4, flow regulating valve 5 (flow switch), dripping oil pipe 6 and joints, as figure 1 shown.

[0021] Considering that the lubricating part is an open gear, the system uses No. 220 gear lubricating oil with a relatively high viscosity. This type of gear oil has strong adhesion, which can prevent the gear oil from directly flowing out of the tooth surface. When the gears mesh with each other, the gear oil is squeezed to the tooth root, and when the gears are not meshing, the gear oil slowly spreads out. The meshing surfaces are always lubricated by lubricating oil, so as to realize the long-term lubrication of the gears.

[0022] This lu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com