Dynamic compaction machine automatic lubricating system and control method thereof

A technology of automatic lubrication and dynamic compaction machine, applied in the direction of gear lubrication/cooling, mechanical equipment, transmission parts, etc., can solve the problems of high labor cost, difficulty in manual grease filling, time-consuming and labor-intensive grease filling work, etc. To achieve the effect of saving labor costs and efficient lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] For ease of understanding, the present invention will be further described below in conjunction with the accompanying drawings.

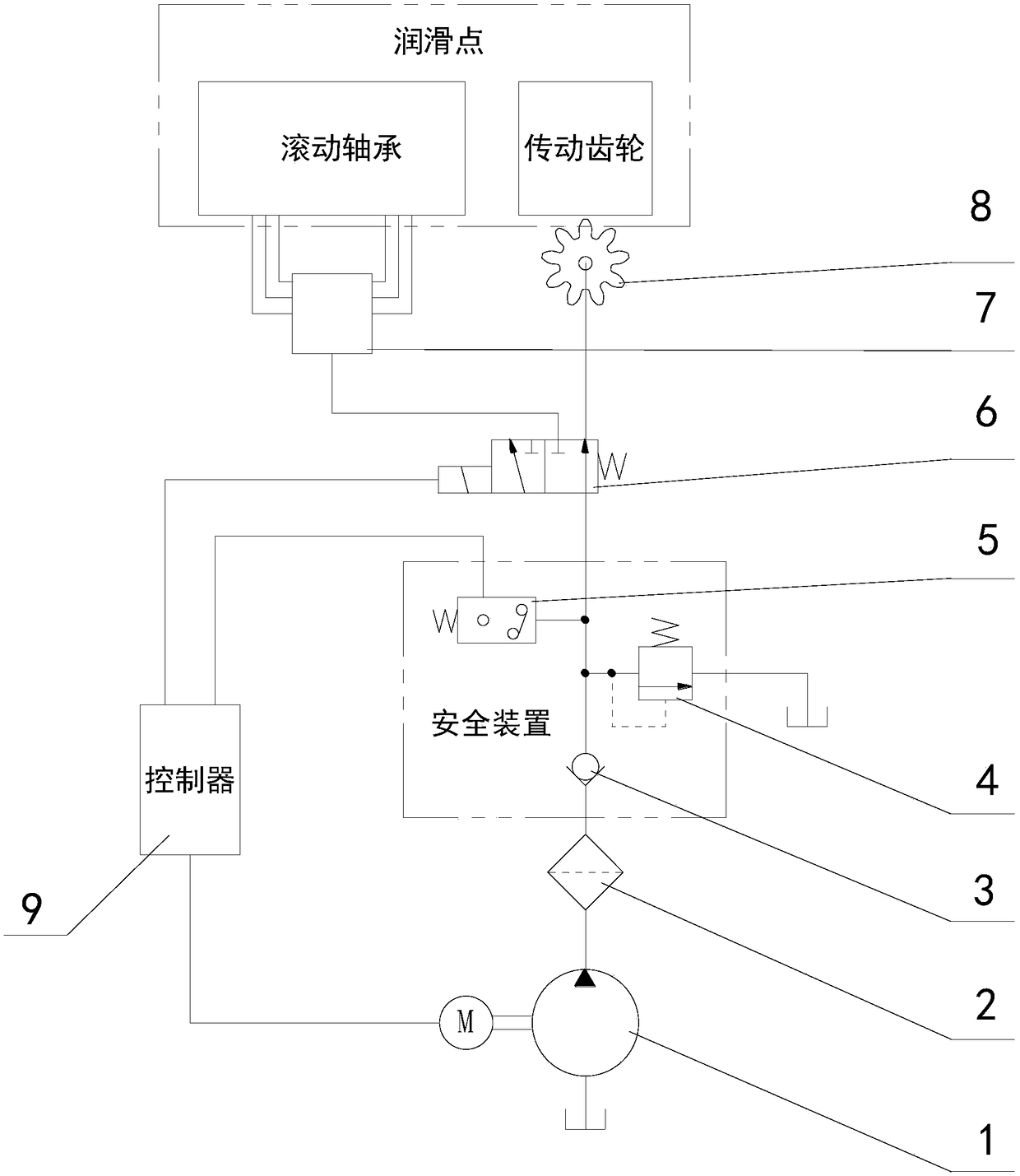

[0035] see figure 1 , is a schematic diagram of the principle of an automatic lubrication system for a dynamic tamping machine provided by an embodiment of the present invention. The automatic lubrication system for a dynamic tamping machine includes an electric lubrication pump 1, an electromagnetic reversing valve 6, a lubrication gear 8, a distributor 7 and a controller 9 .

[0036] Wherein, the controller 9 has a time setting unit and a timing unit, the electric lubricating pump 1 and the electromagnetic reversing valve 6 are electrically connected to the controller 9, and the inlet of the electromagnetic reversing valve 6 is connected to the outlet of the electric lubricating pump 1 through a pipeline .

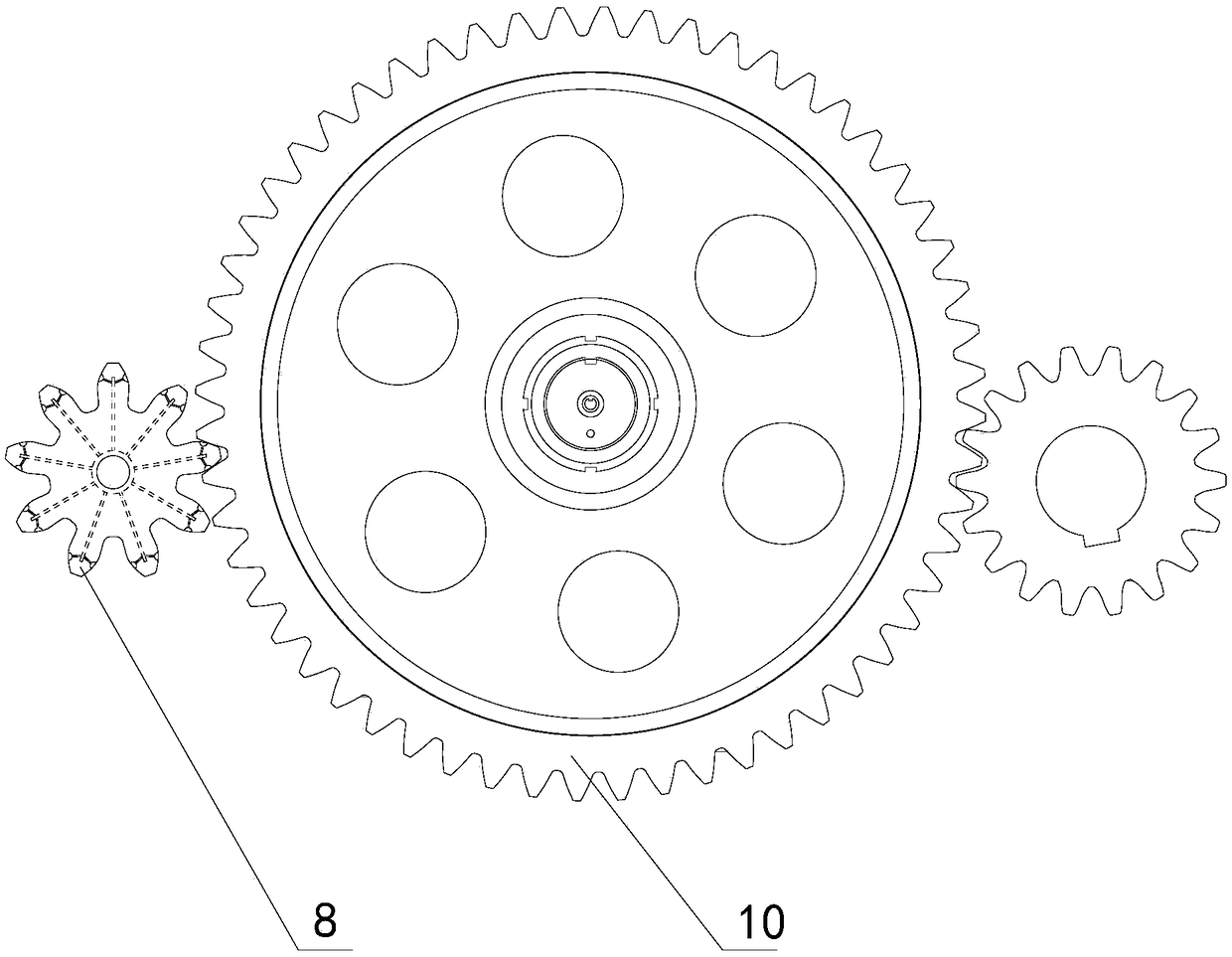

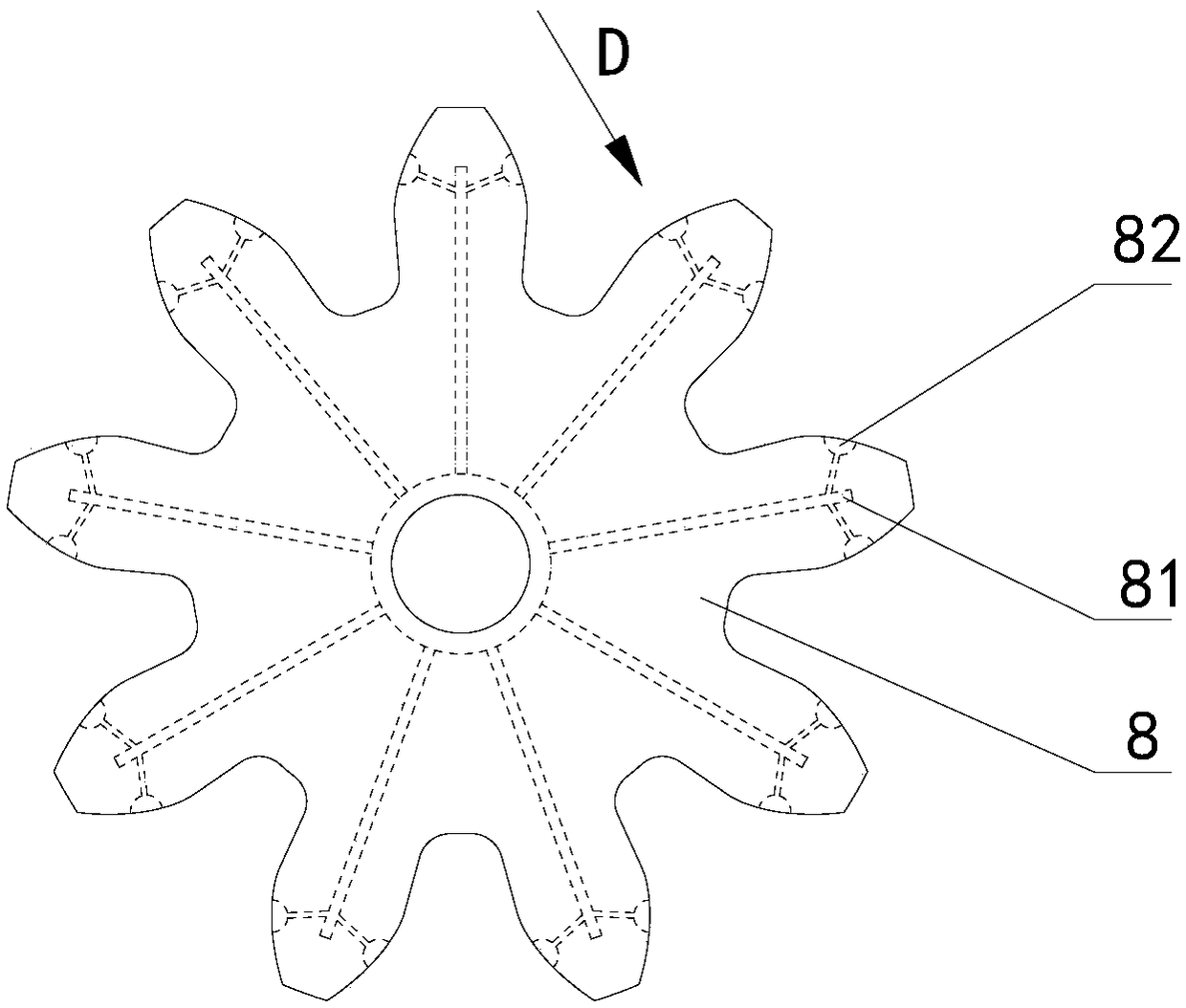

[0037] The lubricating gear 8 is used for the transmission gear 10 in the hoisting device of the dynamic compactor (see figure 2 )...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com