Twin lubrication tank filling system

a filling system and lubrication oil technology, applied in the direction of lubricant transfer, lubrication elements, thin material processing, etc., can solve the problems of interfering with the refilling of the tanks, unable to ensure that both tanks are filled with lubrication, and difficulty in ensuring that both tanks are lubricated without overfilling one tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

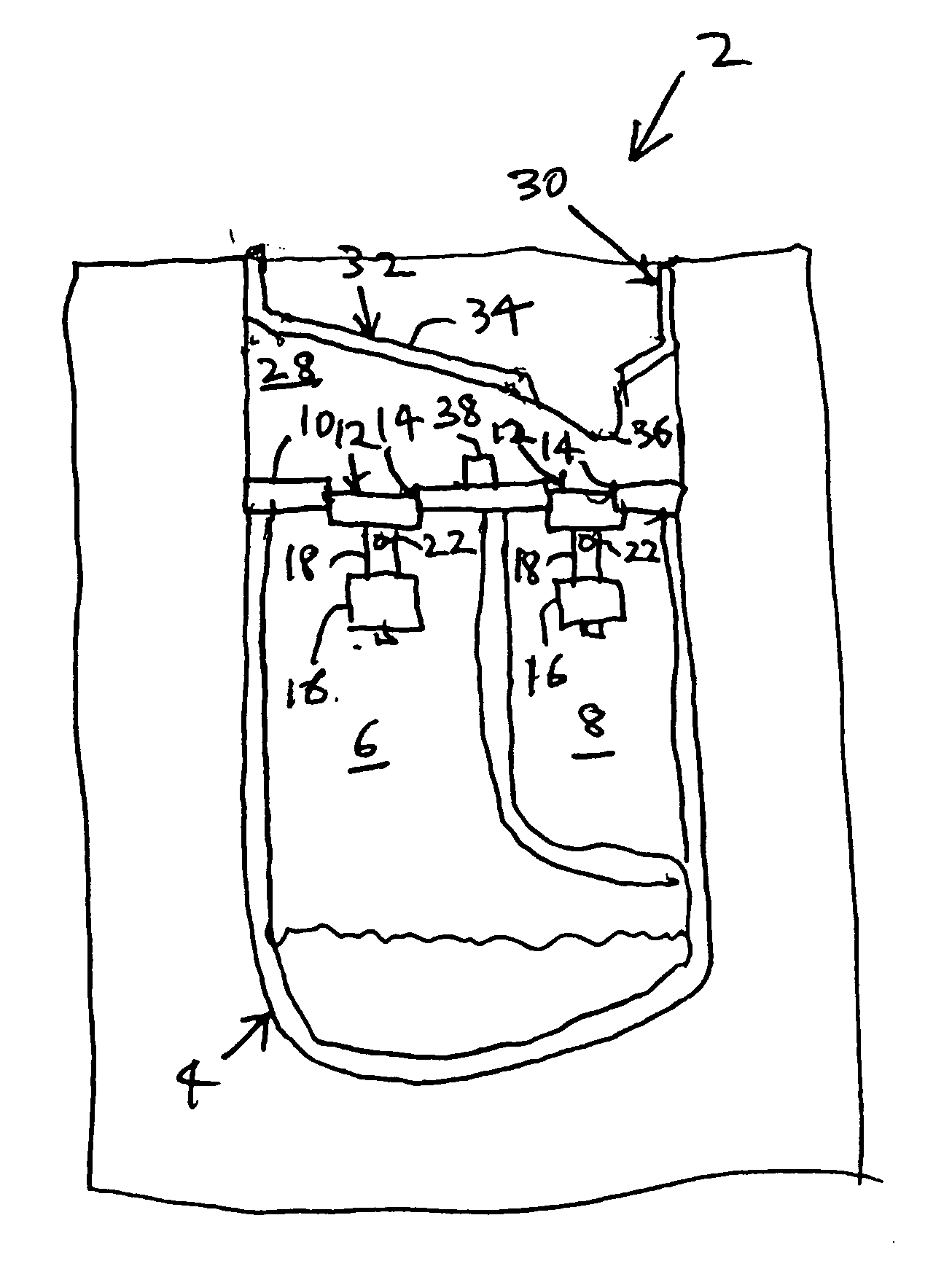

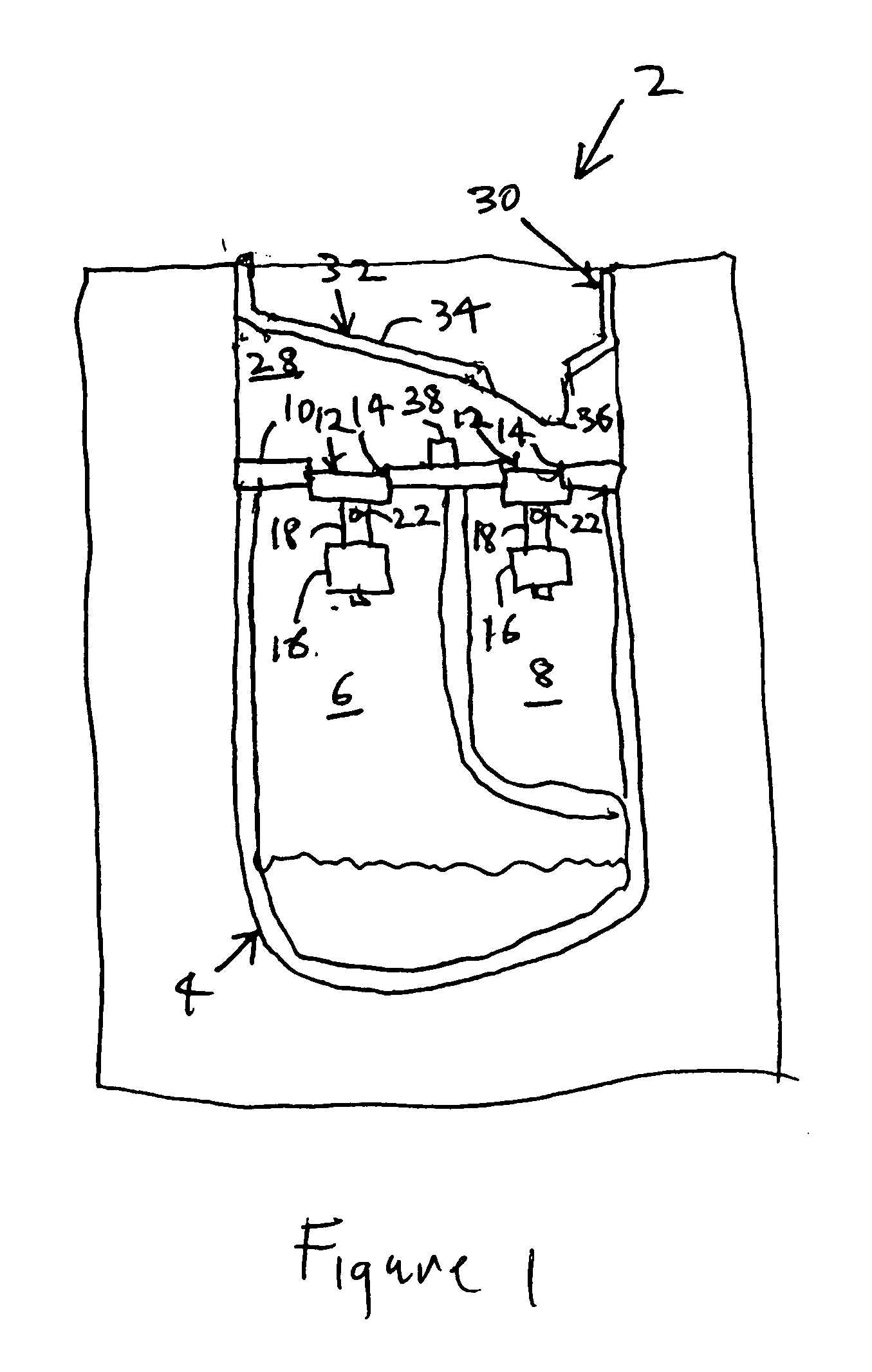

[0012]FIG. 1 is a cut-away side view of machinery, such as a gearbox 2, that incorporates a twin lubrication oil tank filling system 4 according to one possible embodiment of the invention. By way of example as illustrated, the gearbox 2 is designed for an aeronautical APU, but the gearbox 2 may be configured for any other application where it may be used to couple a prime mover to a load. The twin tank filling system 4 comprises a primary oil tank 6 to supply oil for the gearbox 2 and a secondary oil tank 8 to supply oil to at least one load or accessory attached to the gearbox 2, such as a generator (not shown).

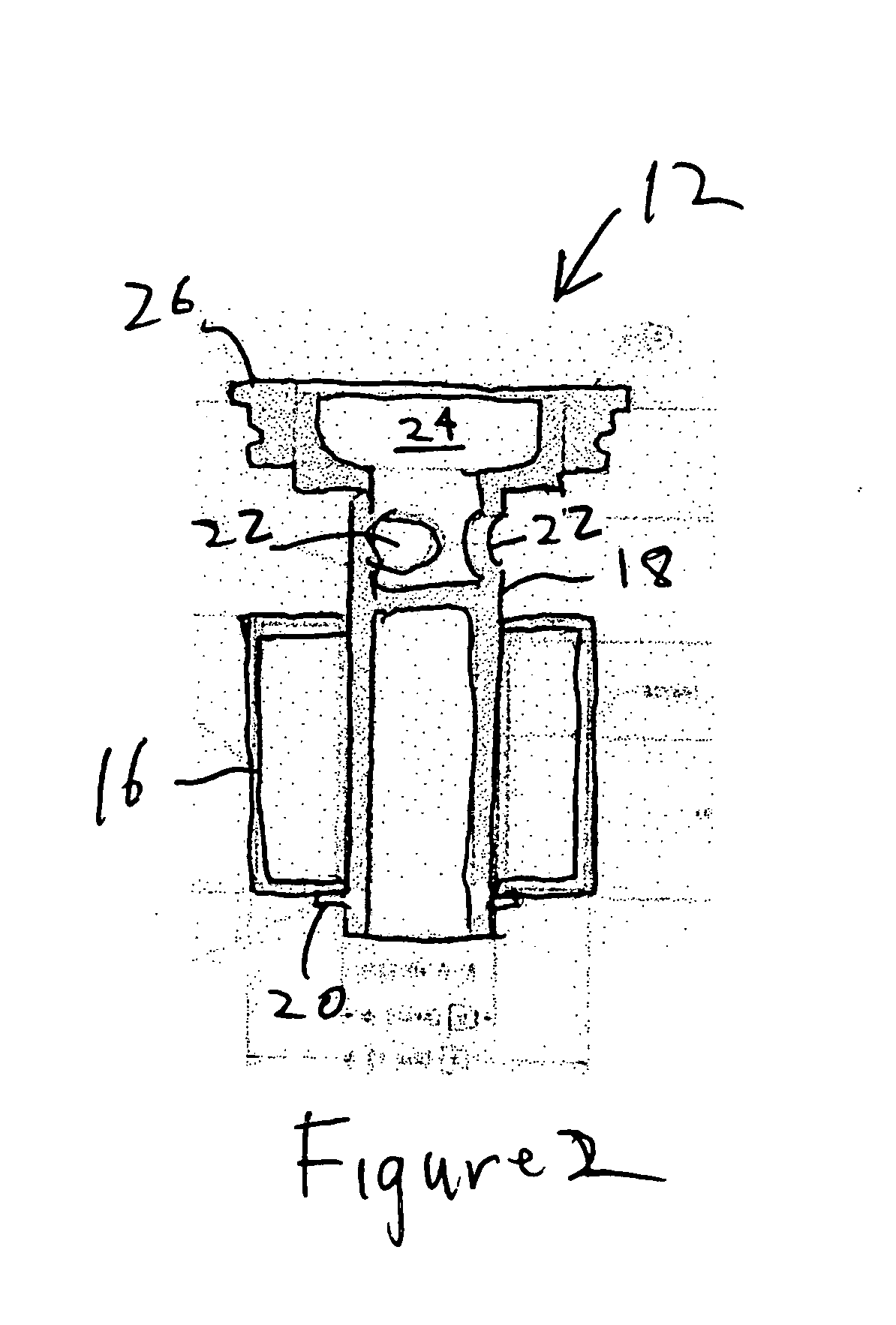

[0013] The primary oil tank 6 and the secondary oil tank 8 have a “full” level at the same height as controlled by a baffle plate 10 common to both the primary oil tank 6 and the secondary oil tank 8. A float valve 12 sits in the primary oil tank 6. Another float valve 12 sits in the secondary oil tank 8. Each float valve 12 mounts in a mating aperture 14 that passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com