Outboard engine and separated lubricating system thereof

A technology of outboard motors and lubrication systems, applied in the direction of engine lubrication, closed-circuit lubrication systems, engine components, etc., can solve the problems of large consumption of lubricating oil, inability to change in time, too thick lubricating oil, etc., and achieve favorable cooling And lubrication, high viscosity, sufficient lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

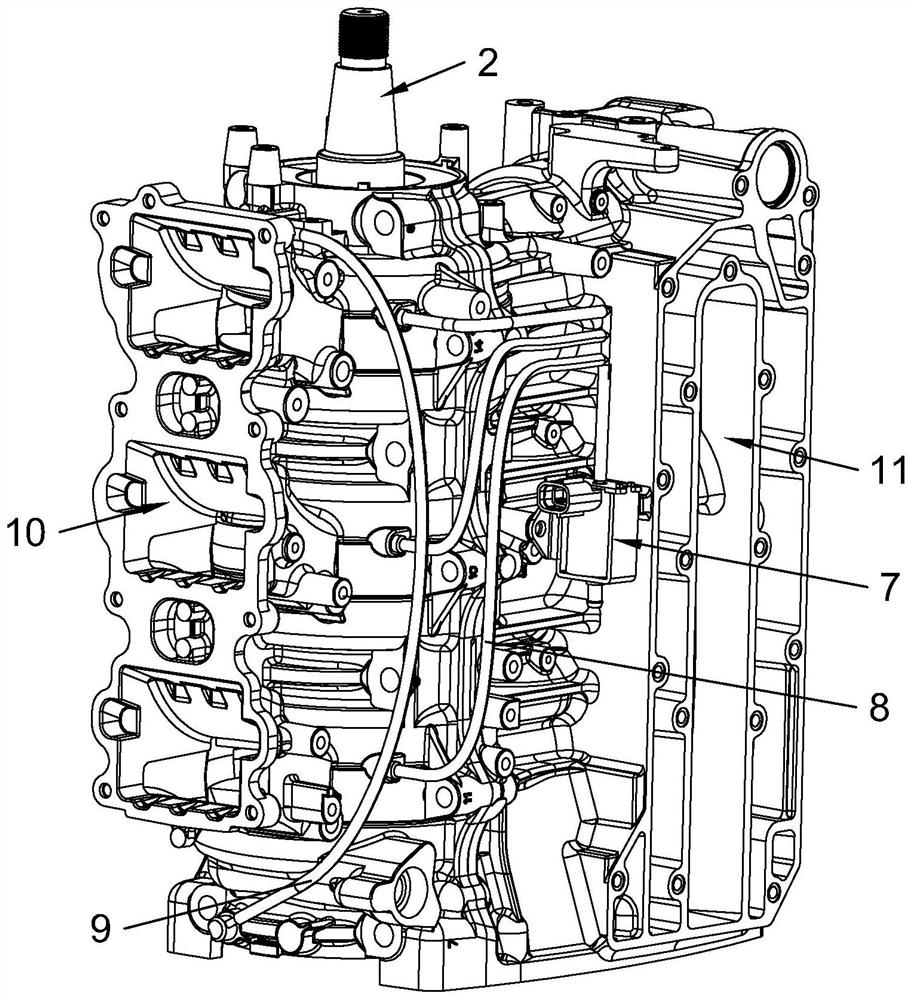

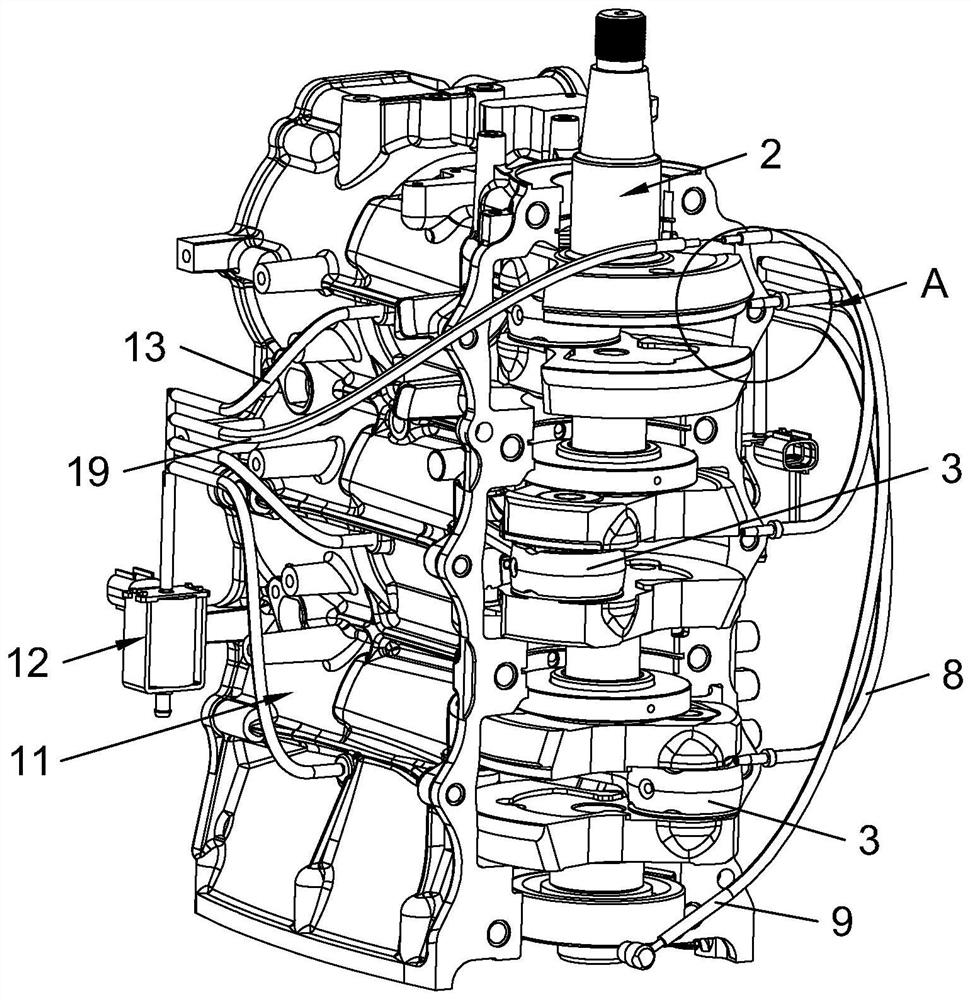

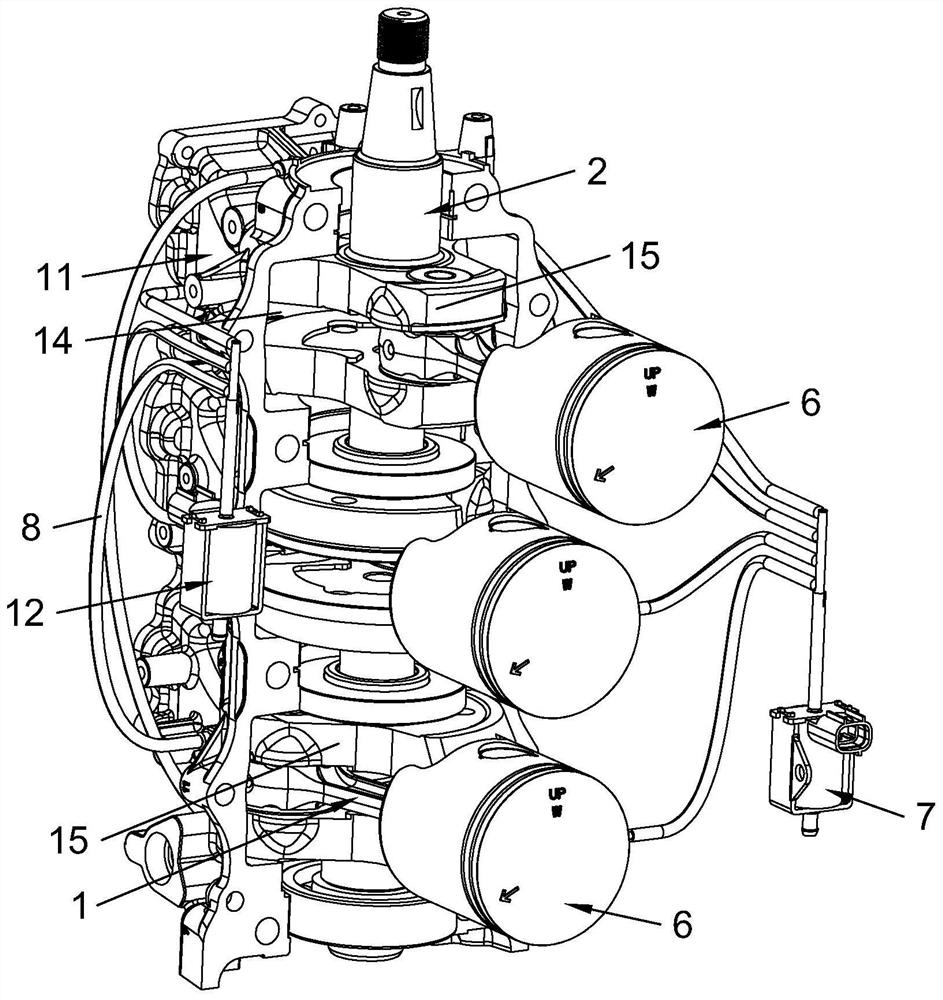

[0029] The present invention will be further described with reference to the accompanying drawings.

[0030] This embodiment discloses a separate lubricating system for an outboard motor, such as Figure 1-7 As shown, it includes a crankcase and a power assembly arranged in the cavity of the crankcase. The power assembly includes a connecting rod 1, a crankshaft 2, and a plurality of bearings, wherein the connecting rod 1 includes a connecting rod big end 3 and a connecting rod small end. end and the connecting rod shaft, the large end 3 of the connecting rod is hinged to the crankshaft 2 through the crank pin, the small end 4 of the connecting rod is hinged to the piston 6 through the piston pin, and the piston 6 reciprocates in the cylinder and drives the connecting rod 1 to reciprocate. The connecting rod 1 reciprocates and drives the crankshaft 2 to rotate in the crankcase; the separated lubrication system also includes a lubricating oil tank, a first oil pump 7 and a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com