Device for supplying lubricant to a lubrication point in a machine

A technology of lubricant and lubricant pump, which is applied in the direction of engine lubrication, control of lubricant pressure, lubrication pump, etc., and can solve problems such as lubricant loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

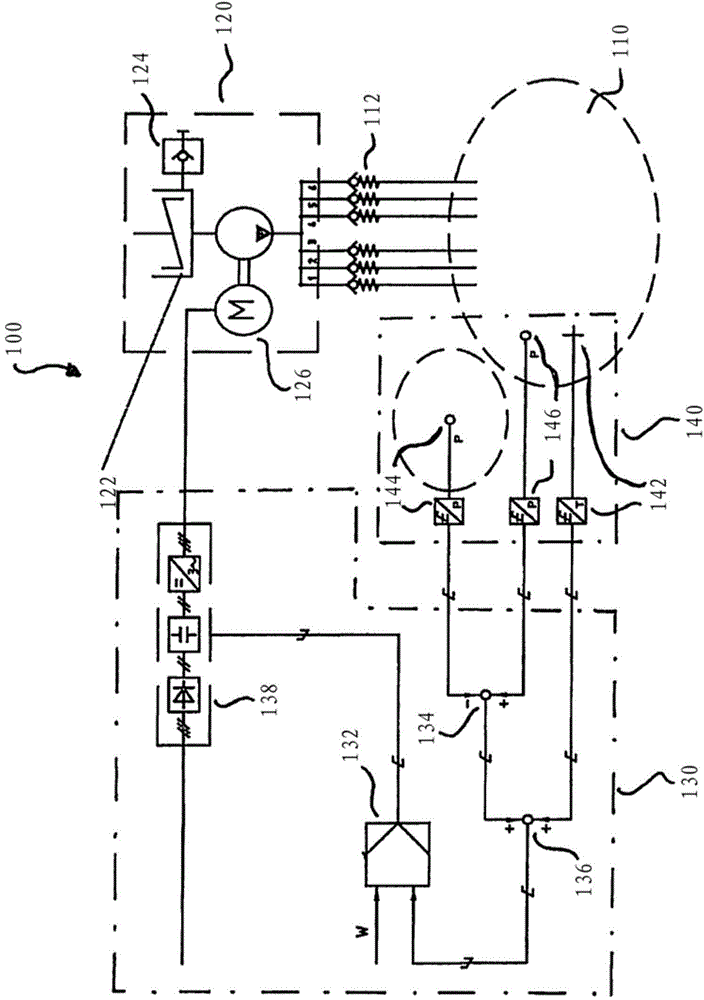

[0018] figure 1 A block diagram of a device 100 for supplying lubricant to a lubrication location 110 in a machine is shown as an example. The device 100 comprises a lubricant pump unit 120 connected to a control unit 130 . The lubricant pump unit 120 supplies lubricant to the lubrication position 110 . The control unit 130 is connected to the lubricant pump unit 120 and regulates the quantity of lubricant supplied by the lubricant pump unit 120 to the lubrication point 110 on the basis of the sensor measurement signals. The sensor measurement signal depends on the measured temperature in the region of the lubrication location 110, the measured pressure in the region of the lubrication location 110, the measured viscosity of the lubricant, the measured dielectric property (or dielectric constant) of the lubricant, The water content of the lubricant is measured, the intensity of the vibrations measured on the parts of the machine and / or the rotational speed measured to the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com