Method and Apparatus for Monitoring and On-demand Lubricating of Industrial Valves

a technology for industrial valves and lubricating devices, applied in the direction of engine pressure, signal processing, lubrication elements, etc., can solve the problems of unlubricated stems, gates, seats, and methods that do not work, and enforce law enforcement requirements for complian

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

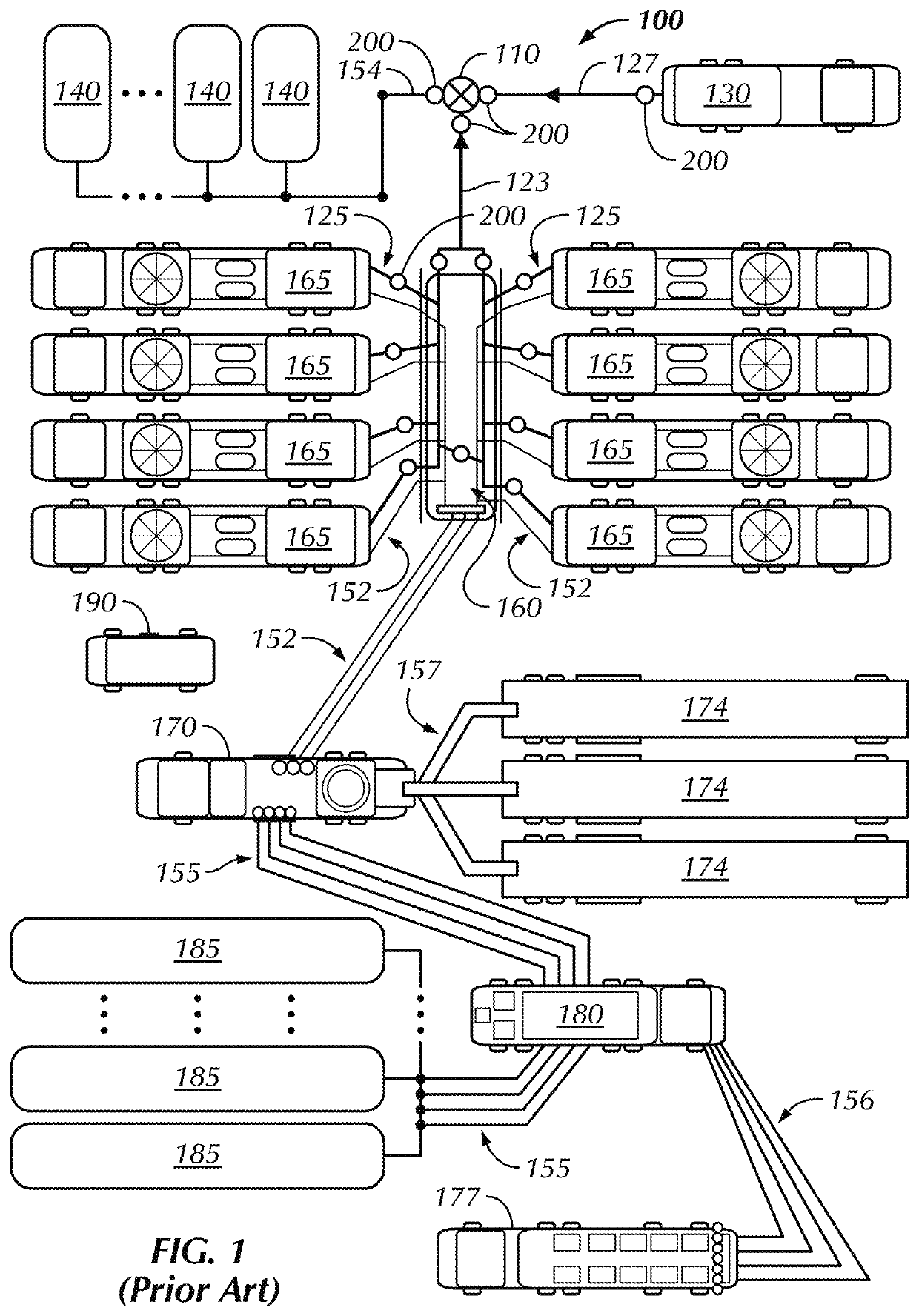

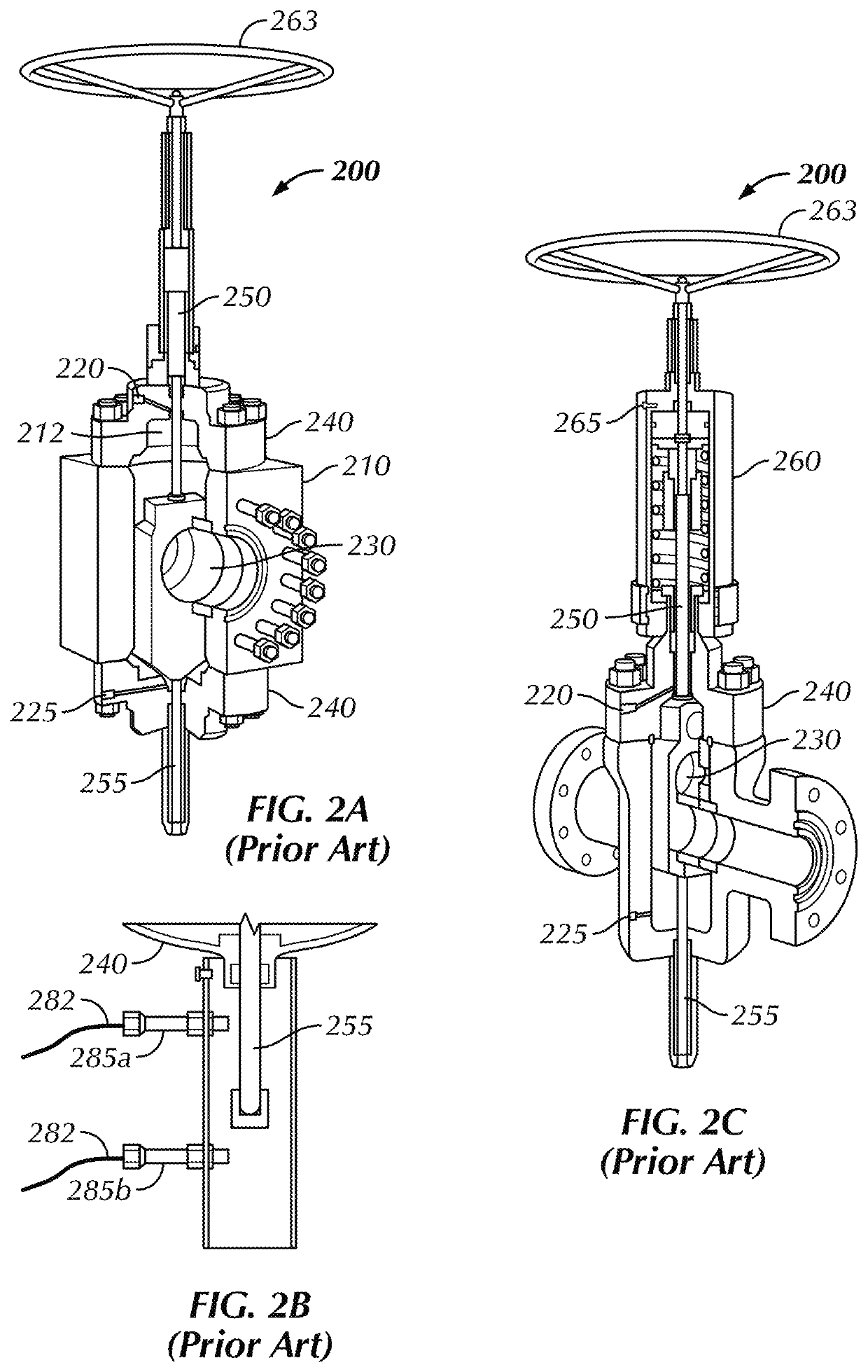

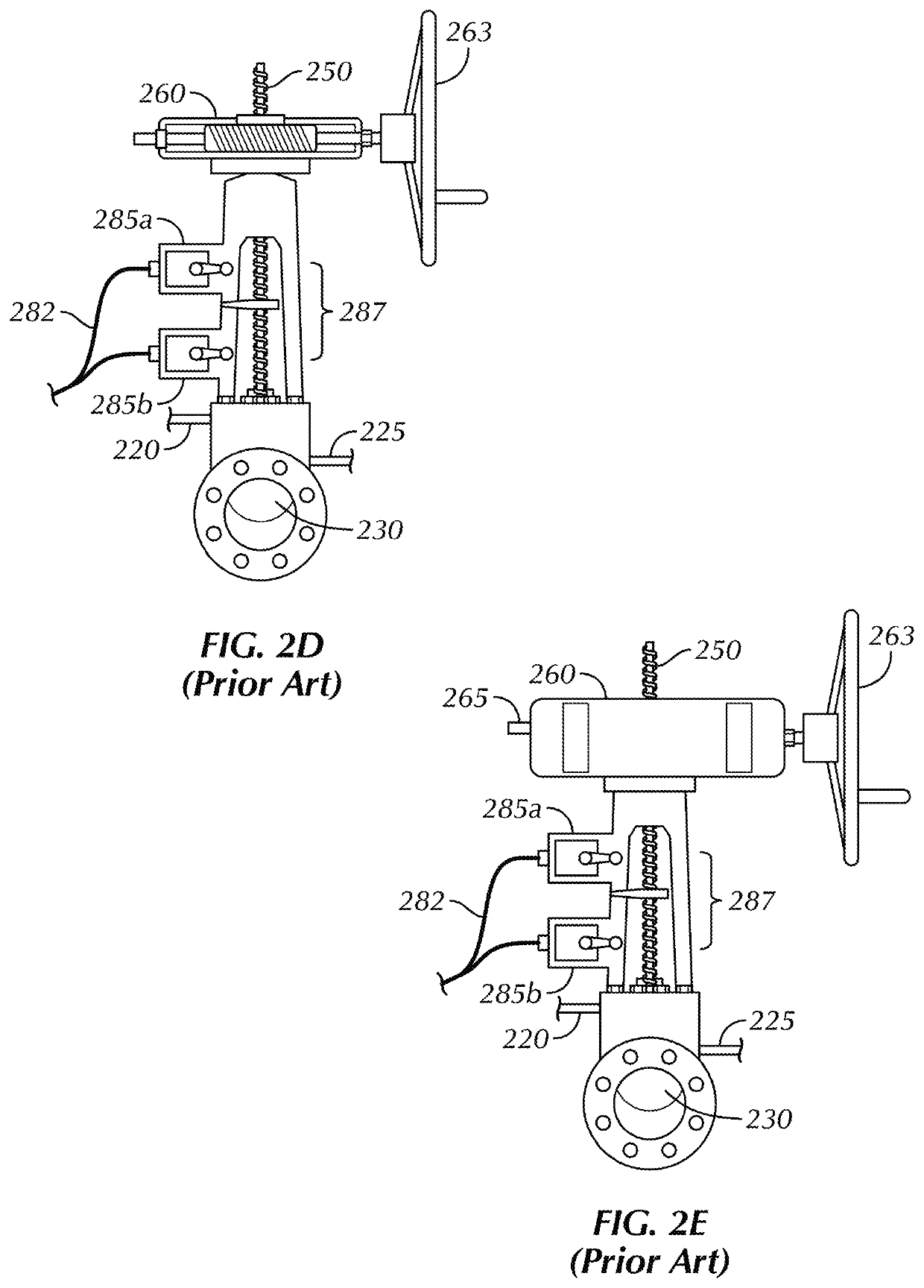

[0046]The innovation described herein automates valve maintenance by monitoring valve operation and delivering lubricant on-demand according to actual usage and coordinating the lubrication of the valve with in-service valve operations. This avoids downtime caused by taking a valve out-of-service for maintenance or more extensive repairs due to improper maintenance.

[0047]The coordination with in-service valve operations also eliminates effects of unnecessary (i.e. ‘maintenance only’) valve operations, and ensure maintenance is performed in accordance with company procedure. Additionally, alleviating maintenance personnel from this routine task lowers their exposure to hazards and increases their availability for other tasks.

[0048]Valve operations are monitored by a programmable logic controller that also controls delivery from a lubricant source to the valve. The logic controller delivers lubricant to the valve when operations require, and the valve is in a condition to accept the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com