Mining explosion-proof type thin oil lubrication station

A kind of thin oil lubrication and mine explosion-proof technology, which is applied in the direction of lubricating parts, engine lubrication, lubricating oil control valves, etc., can solve the problems of limited underground space, reduced thermal efficiency, increased operating costs, etc., and achieves convenient installation of pipelines, Space-saving and cost-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

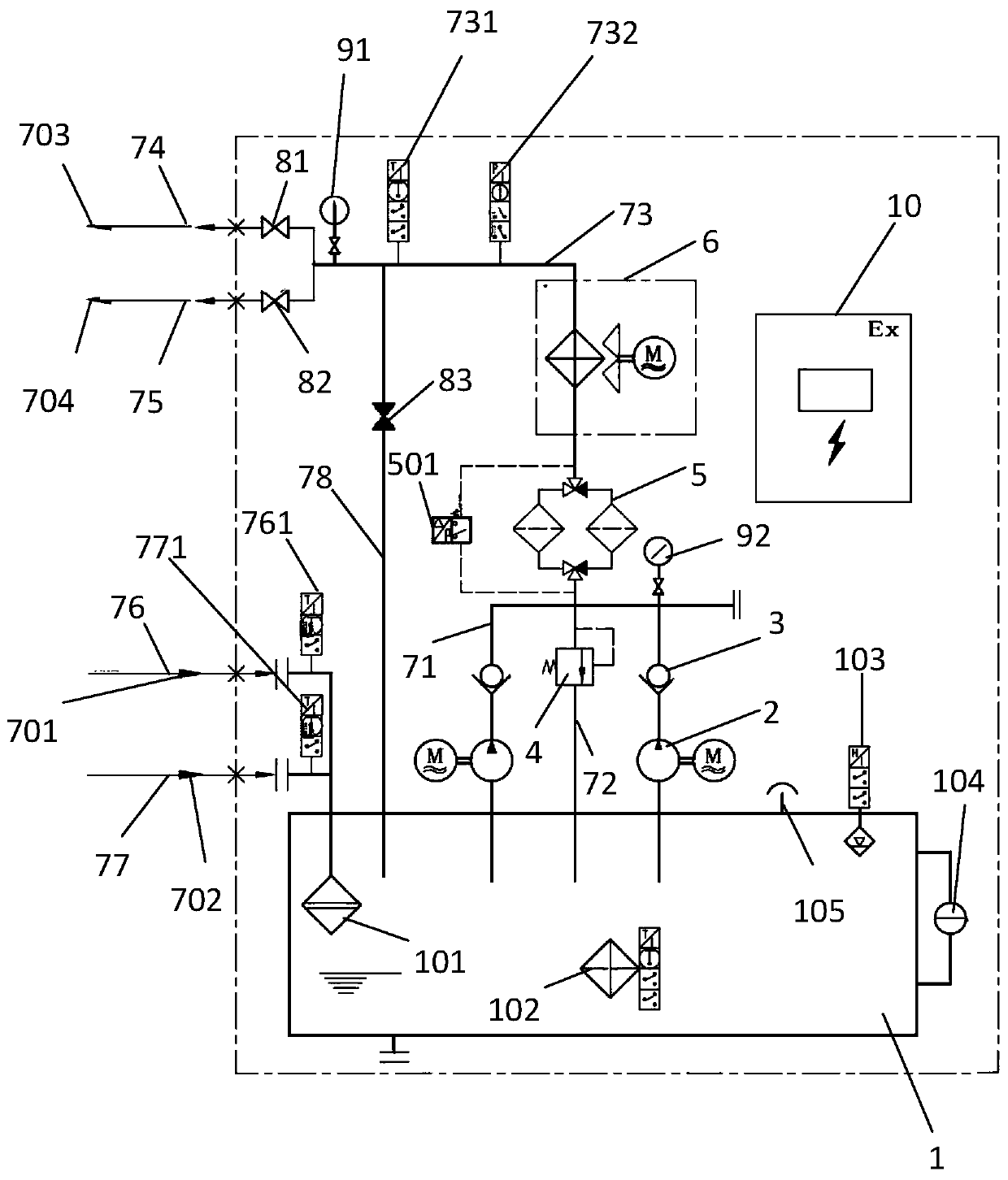

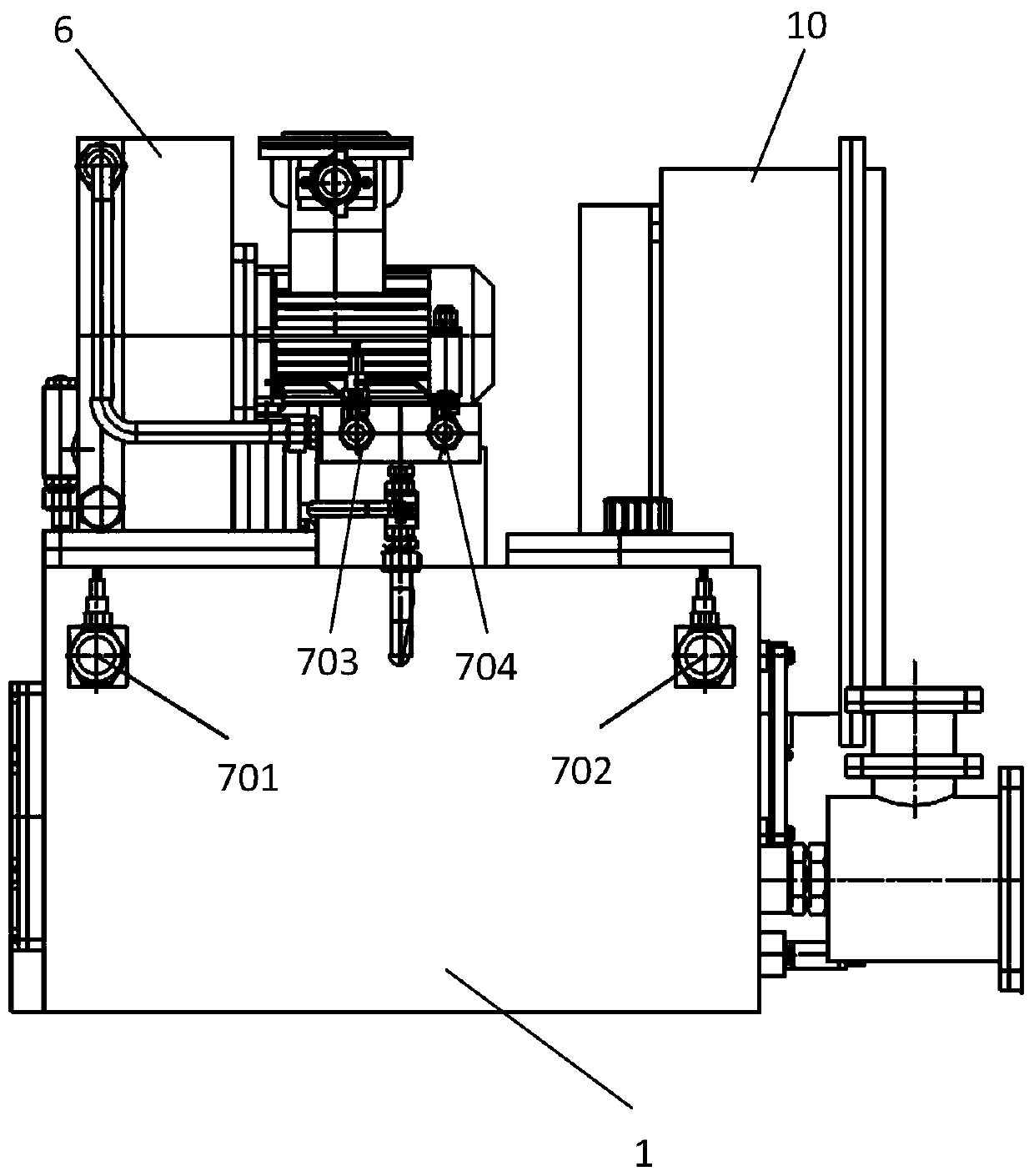

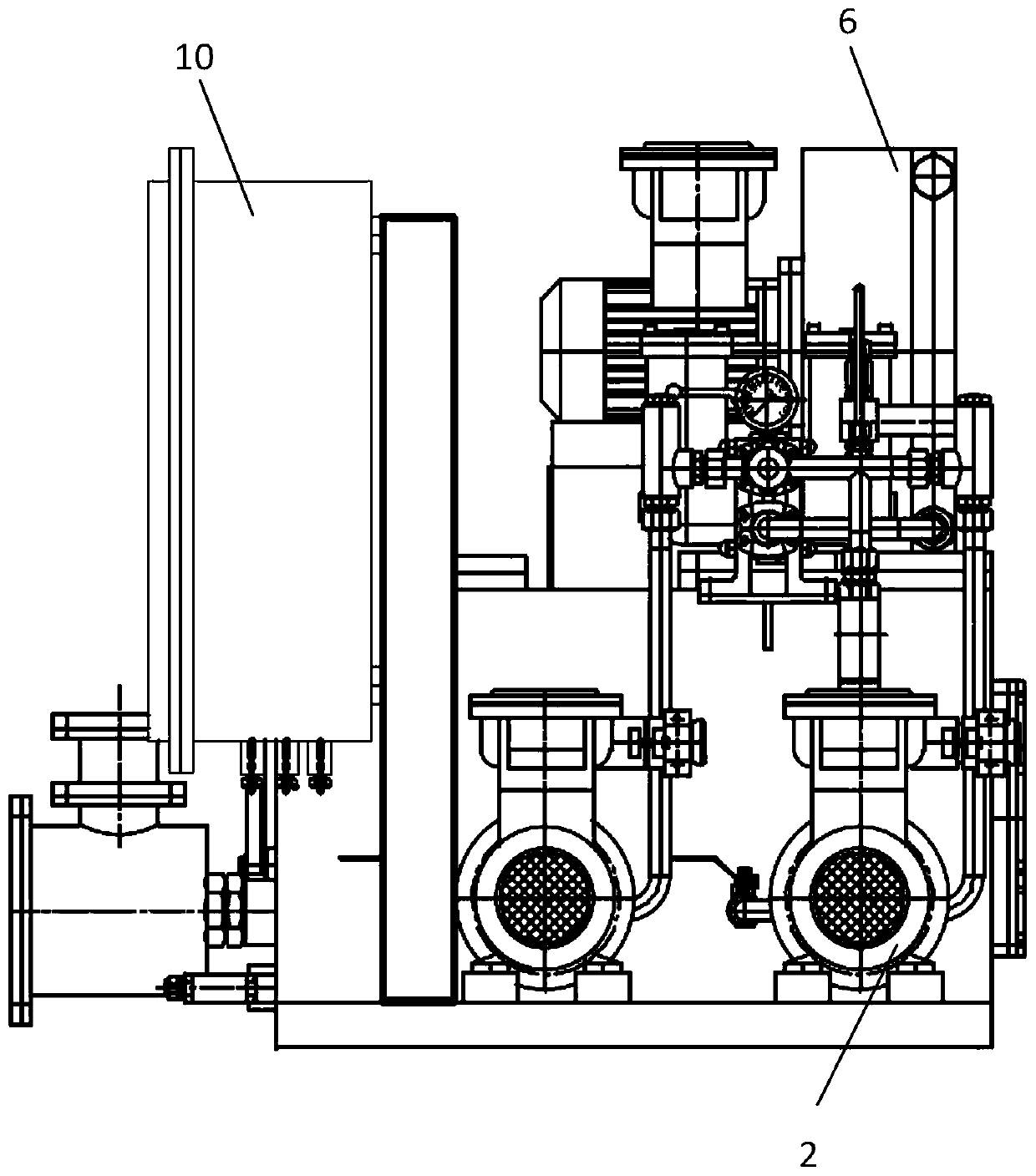

[0024] See Figure 1-Figure 5 In this embodiment, the mining explosion-proof thin oil lubrication station includes a fuel tank 1, an oil outlet pipeline, an oil return pipeline, an oil pump 2, a one-way valve 3, a safety valve 4, a double cylinder filter 5, a cooler 6 and an electric control box 10. The oil return of the oil tank 1 is provided with a magnetic filter device 101, whose main function is to filter out ferromagnetic substances and mechanical impurities in the oil return.

[0025] The oil outlet pipeline includes a first pipeline 71, a second pipeline 72 and a third pipeline 73. One end of the first pipeline 71 and the second pipeline 72 are respectively connected to the fuel tank 1, and the other end of the first pipeline 71 is connected to the oil tank 1. The other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com