Automatic oiling device and method for cigarette packaging machine

A packaging machine, automatic technology, applied in safety devices, transportation and packaging, engine lubrication, etc., can solve the problems of equipment blocking aluminum paper, large surface friction coefficient of aluminum foil paper, etc., to reduce blocking phenomenon, reduce excessive oil Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention. The protection scope of the present invention is not limited by the embodiments, and the protection scope of the present invention is determined by the claims. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

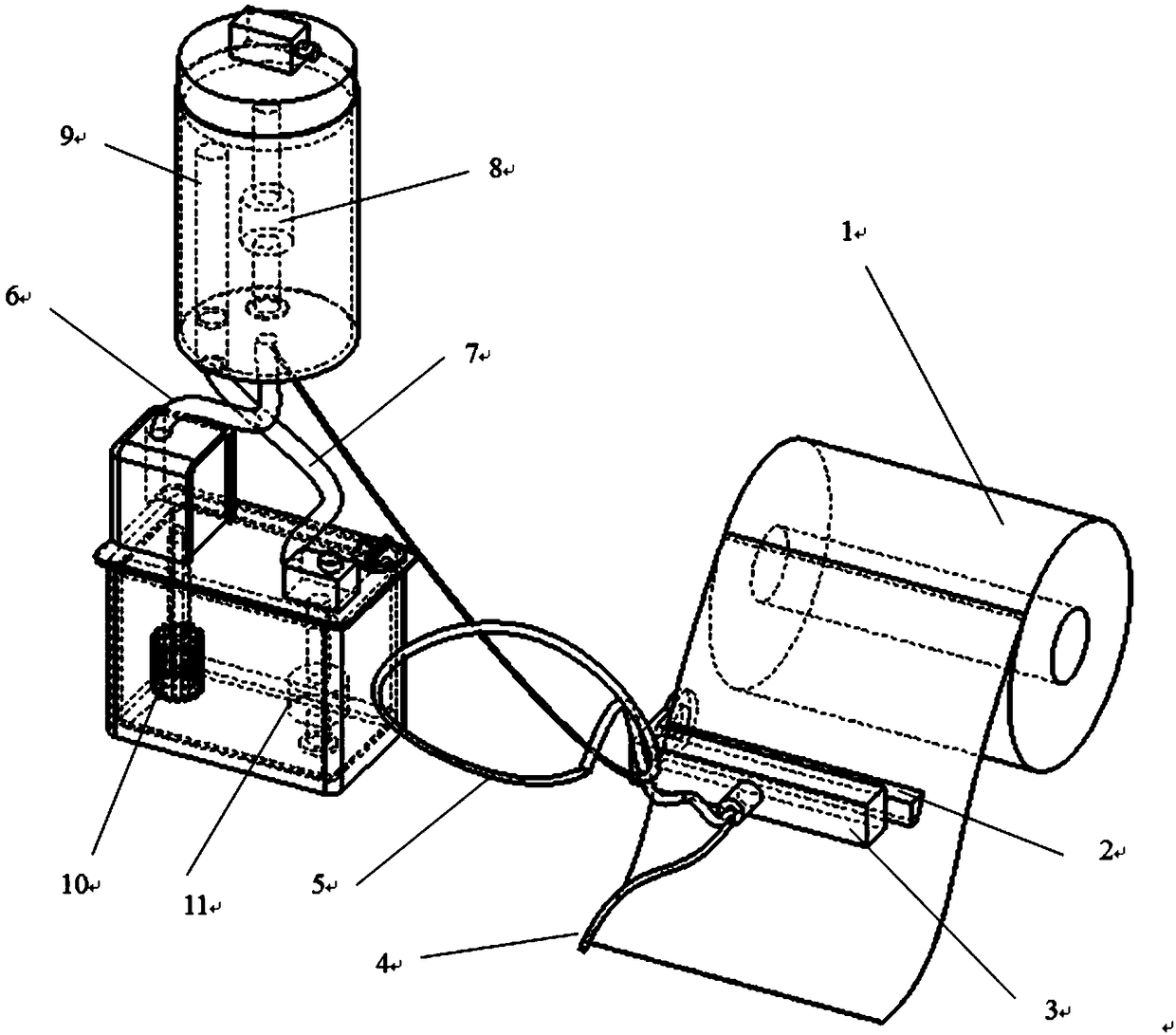

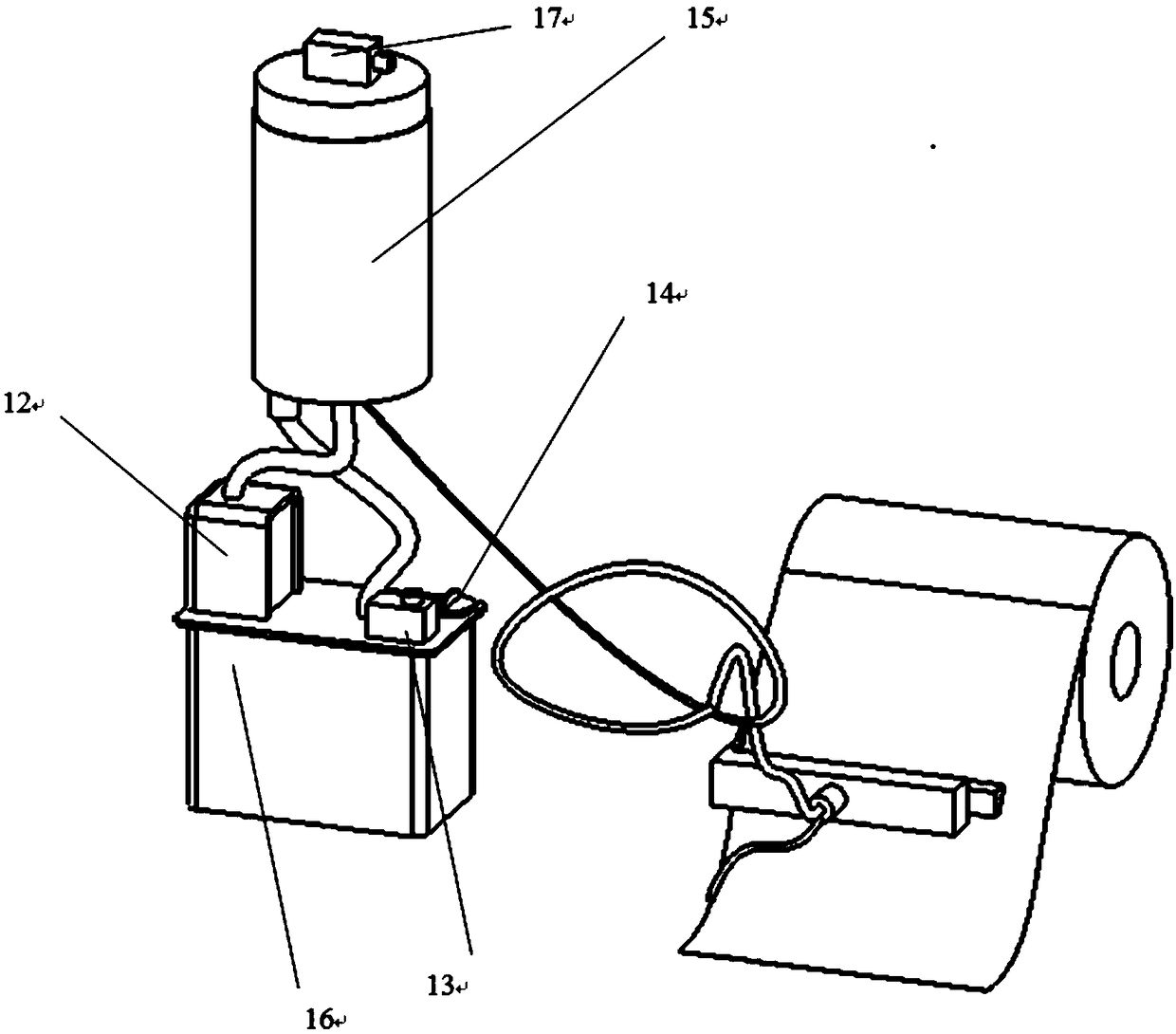

[0033] Such as figure 1 and figure 2 As shown, an automatic oiling device includes a large oil tank 16, a small oil tank 15, an oil pump 12 and linoleum 2, the small oil tank is located above the large oil tank, the large oil tank is a regular box, and the material of the box is transparent or translucent cloth oil seepage The material does not undergo any chemical change with oil, and there is a rotatable fuel tank cover 14 on the upper surface of the casing, which is used to refuel the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com