Production process of nylon-6 coarse-denier high-strength yarns

A production process and nylon technology, which is applied in the field of production technology of nylon 6 coarse denier high-strength yarn, can solve problems such as the inability of equipment to meet production needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

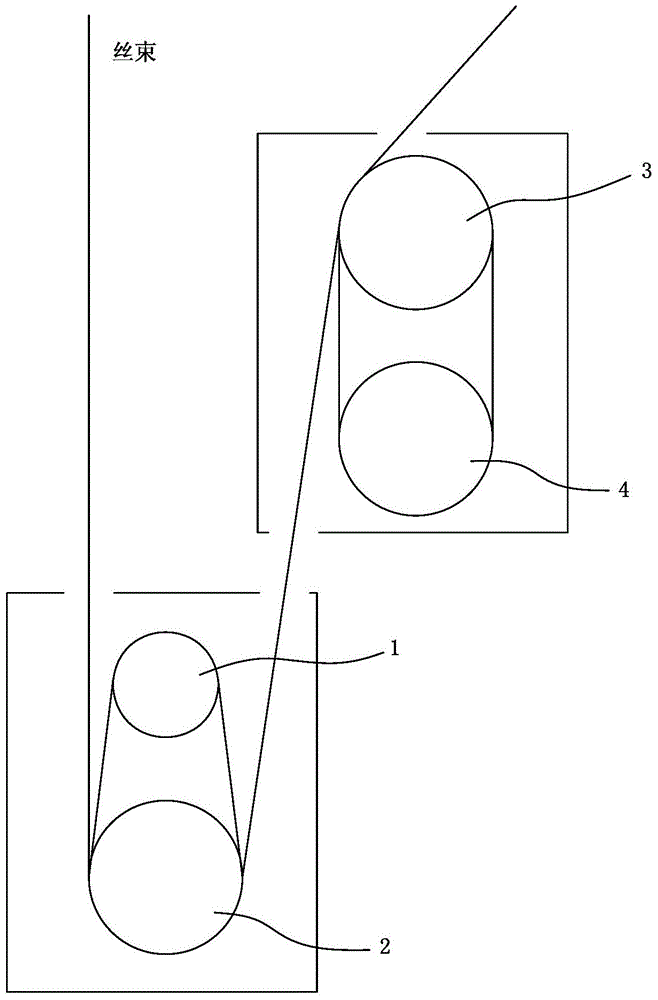

[0026] A production process of nylon 6 coarse-denier high-strength yarn, including slicing→melting→metering→spinning→cooling→oiling→pre-network→drawing and setting→main network→winding.

[0027] Slice, select the nylon 6 slice that viscosity is 2.8 for use, this slice is the nylon 6 slice that Taiwan Ji Sheng nylon slice company produces, and product model is HP3402.

[0028] Melting, using a screw extruder to heat-process the melt into the slice, and transport it to the metering pump in the metering step through the melt pipeline insulated by biphenyl. The temperature of the screw extruder is 270-280 ° C. Biphenyl The holding temperature is 275°C, and the shear rate of the melt pipe is 17-25sec -1 .

[0029] Metering depends on the gap between the two interlocking gears of the metering pump for precise metering, and continuously delivers a certain pressure of the melt to the spinning assembly.

[0030] Spinning, the melt that enters the spinning assembly is filtered and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com