Roll grinding on-line electrostatic oiling device and method

A technology of electrostatic oiling and rolling, which is applied in the field of rolling anti-rust to achieve the effect of reducing labor intensity, uniform oiling and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

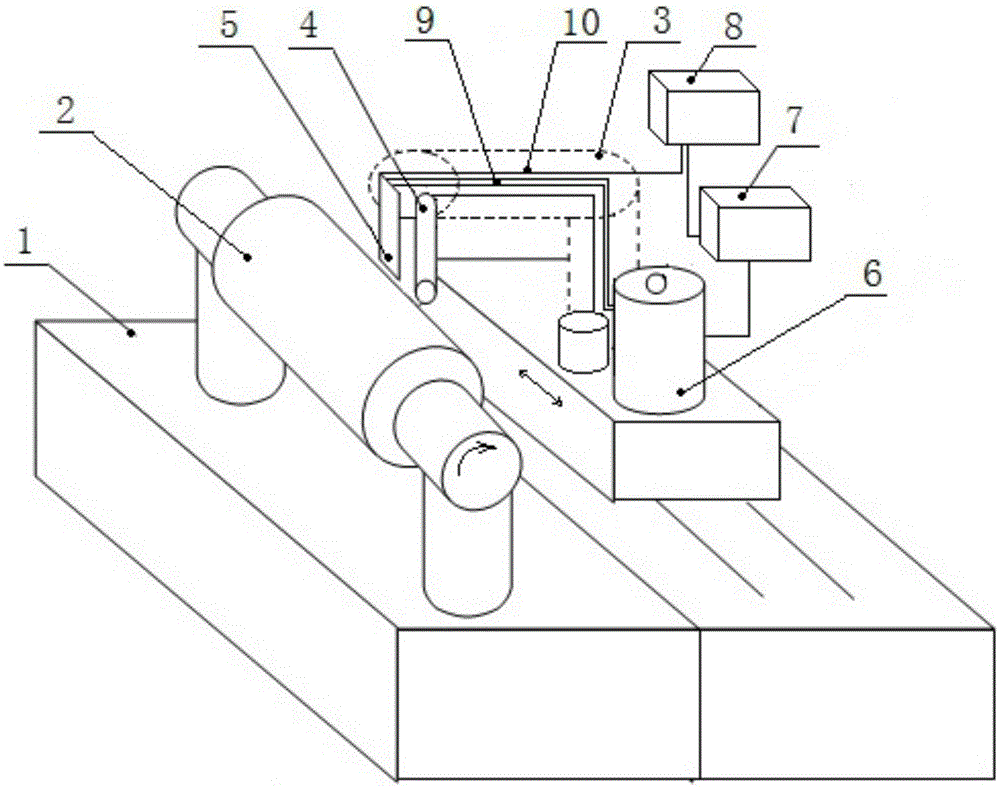

[0027] figure 1 Shown is the structural representation of the present invention.

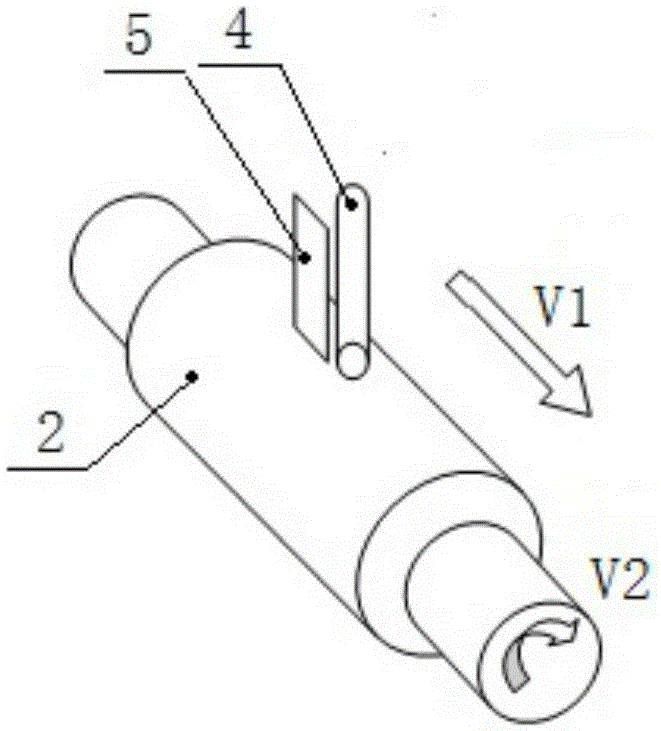

[0028] The present invention comprises grinder body 1, roll 2 and grinding wheel head bracket 3, is provided with oiling device on grinding wheel head bracket 3, and oiling device is composed of purging device 4, high-voltage electrostatic generating device 8, oiling tank 5, oil supply and The heating device 6 and the electric control system 7 are integrated and installed on the grinding wheel head bracket 3 for online oiling of the grinding machine roll grinding.

[0029] The oiling tank 5 is provided with an oiling knife beam, which is integrally arranged on the grinding wheel head bracket 3. During operation, the grinding wheel head bracket 3 moves axially along the roll 2, and the oiling tank 5 installed thereon moves synchronously.

[0030] The edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com