Method and system for engine oil level sensing

A technology of engine and oil level sensors, applied in the direction of engine level, engine speed, engine operating parameters, etc., can solve problems such as not easy to detect or distinguish, undetectable, engine deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

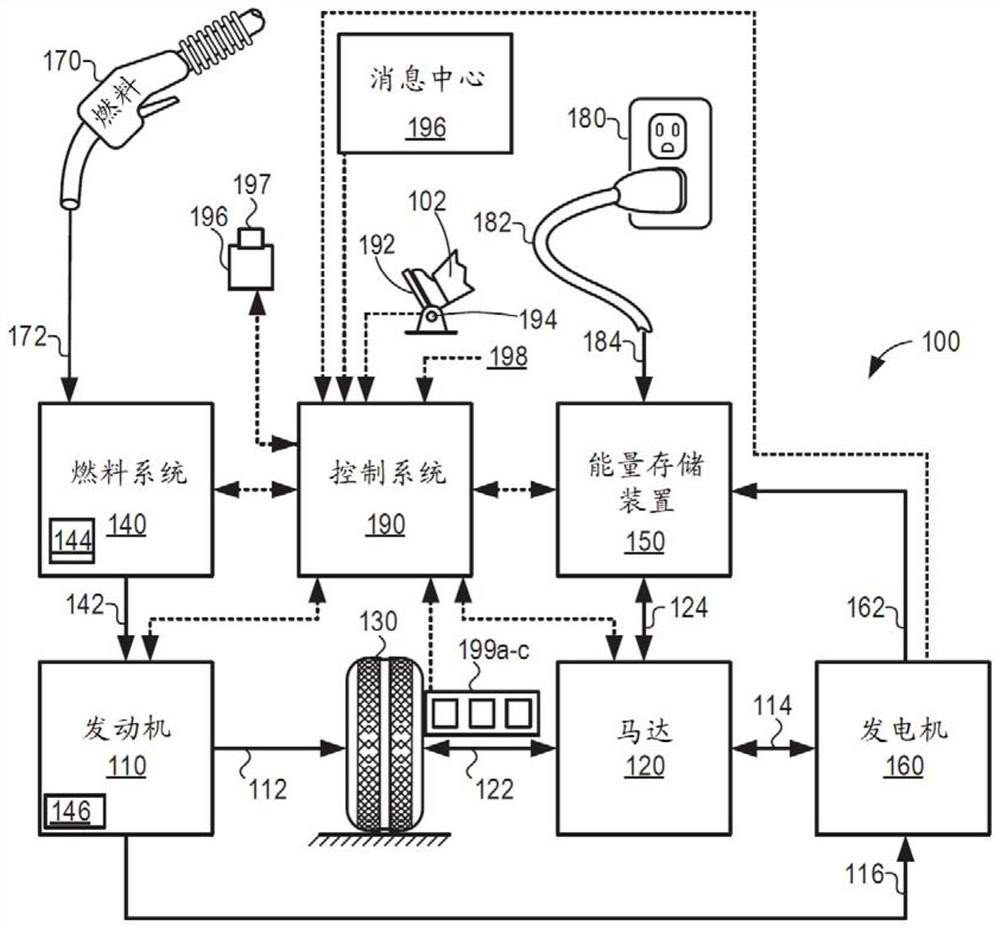

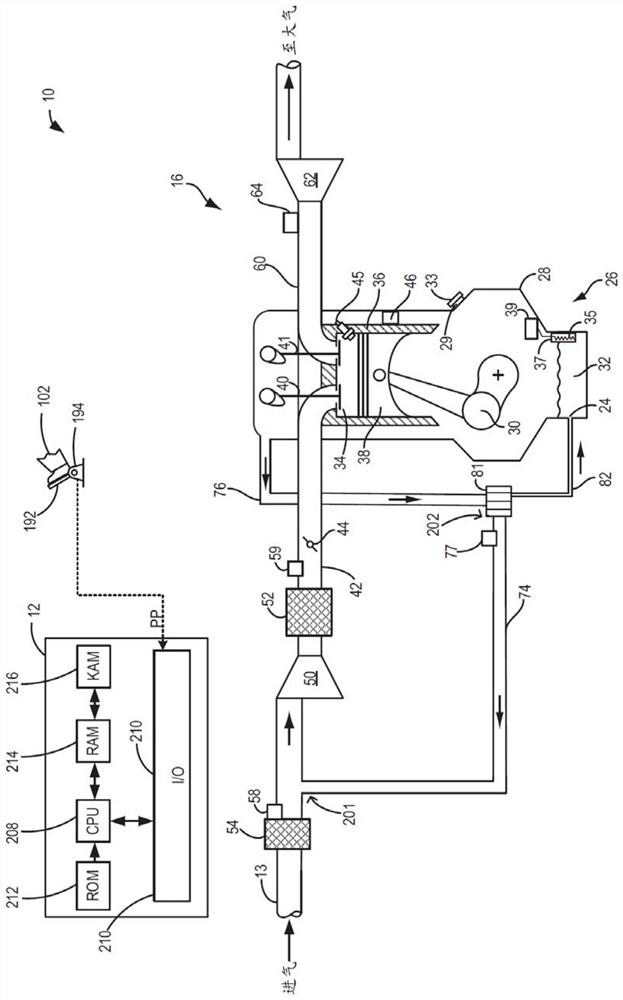

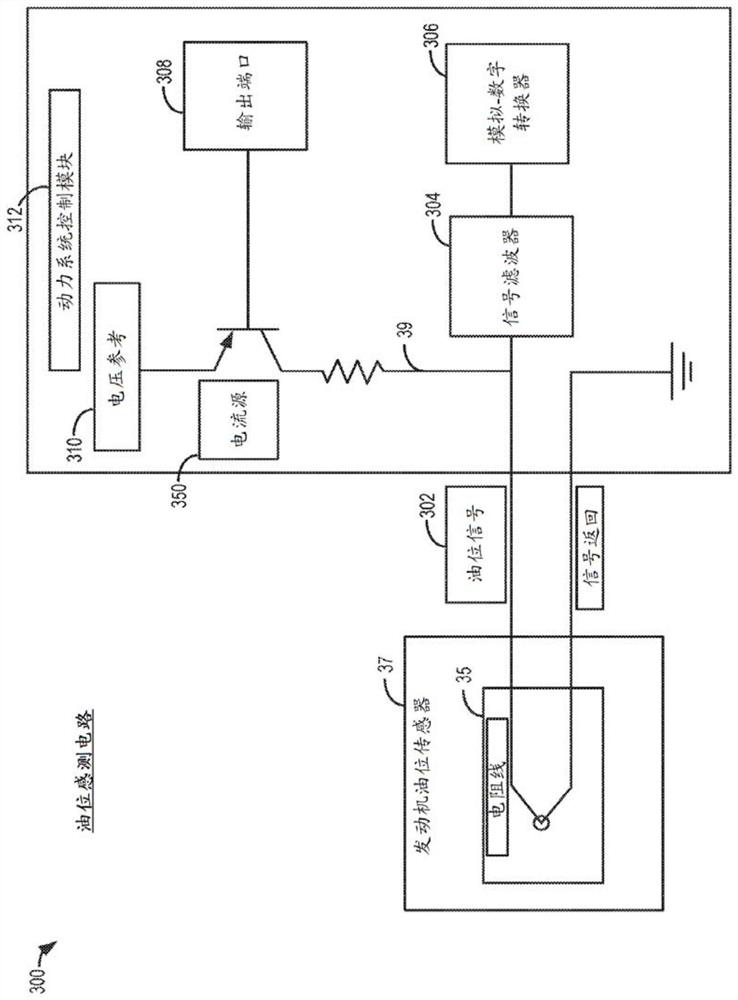

[0016] The following description relates to systems and methods for estimating an oil level in an engine system while the vehicle is running. can be estimated at figure 1 connected to the vehicle system figure 2 engine oil level in the engine system. Engine oil level sensing can be accomplished via a resistive wire probe, such as via image 3 The circuit is connected to the power supply. The engine controller can be configured to execute control routines such as Figure 4 An exemplary routine for sensing engine oil level when data related to vehicle dynamics meets selected criteria. Vehicle dynamics can be learned via vehicle lateral and longitudinal acceleration as well as engine speed and vehicle speed. exist Figure 5 to Figure 6 An example scenario of real-time engine oil level assessment during vehicle motion is shown at . exist Figure 7 An exemplary transfer function for relating sensor output to oil level is shown at .

[0017] figure 1 An exemplary vehicle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com