Automatic container transfer equipment for nuclear industry

A nuclear industry and container technology, which is applied to containers, mechanical equipment, and containers to prevent mechanical damage. It can solve the problems of tank damage, high friction of components, and easy noise generation, so as to increase the scope of application, ensure service life, The effect of avoiding major accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

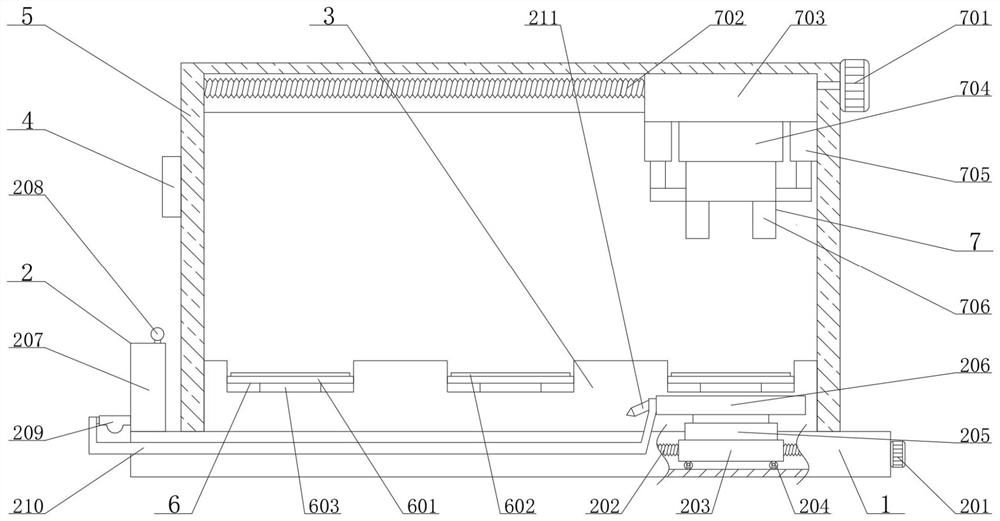

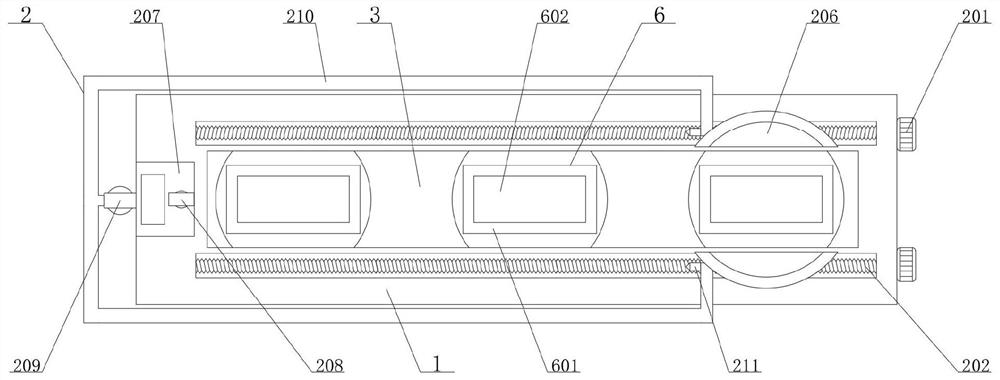

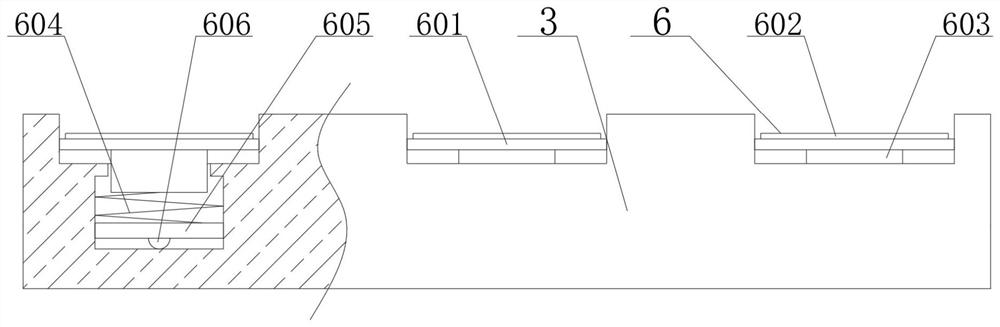

[0023] see figure 1 , figure 2 , image 3 and Figure 4 , the present invention provides a technical solution:

[0024] An automatic transfer device for containers in the nuclear industry, comprising a base 1, a transfer device 2, a buffer detection device 6 and a support device 7, a positioning seat 3 is fixedly connected to the top of the base 1, a transfer device 2 is provided on the inner side of the base 1, and the transfer device 2 includes The first motor 201, the right end of the base 1 is fixedly connected with the first motor 201, and the main shaft of the first motor 201 runs through the base 1, the main shaft of the first motor 201 is connected with the base 1 in rotation, and the end of the main shaft of the first motor 201 is fixedly connected with the first motor 201 A threaded shaft 202, and the first threaded shaft 202 is rotationally connected with the base 1, the outside of the first threaded shaft 202 is spirally connected with a positioning block 203, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com