Continuous reservoir level monitoring

A reservoir and liquid level technology, applied in the field of lubrication systems, can solve problems such as inability to provide accurate lubricant liquid level readings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

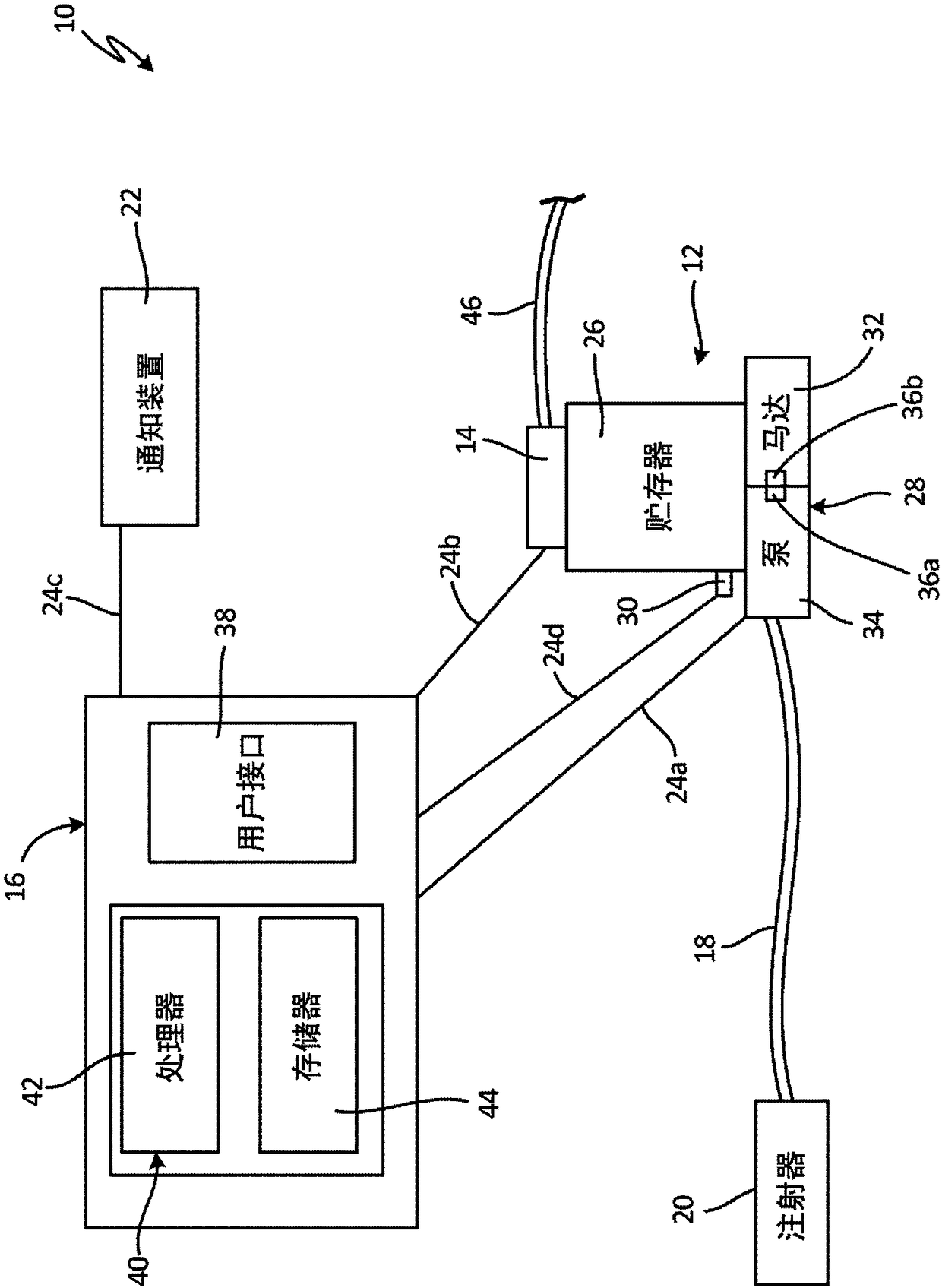

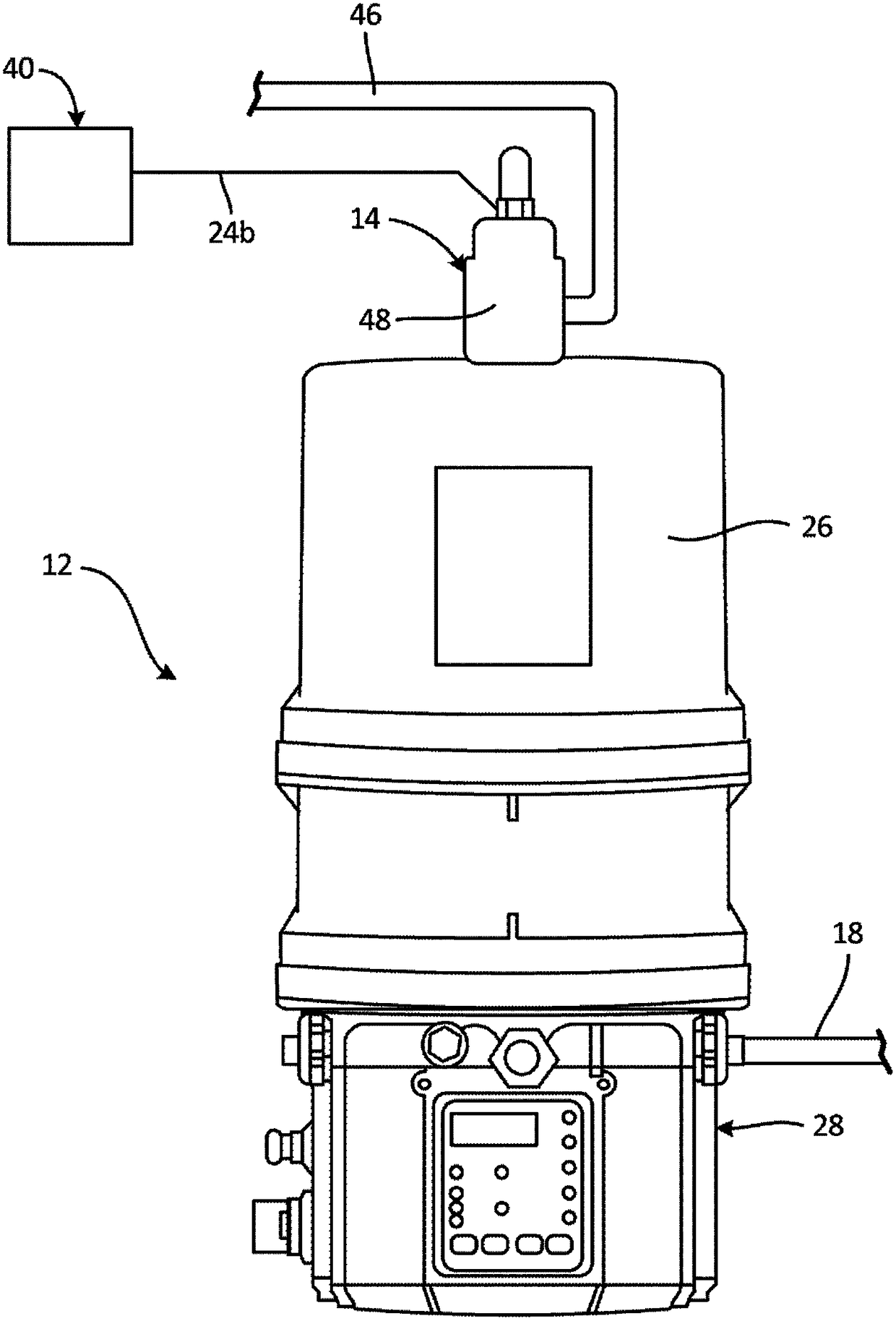

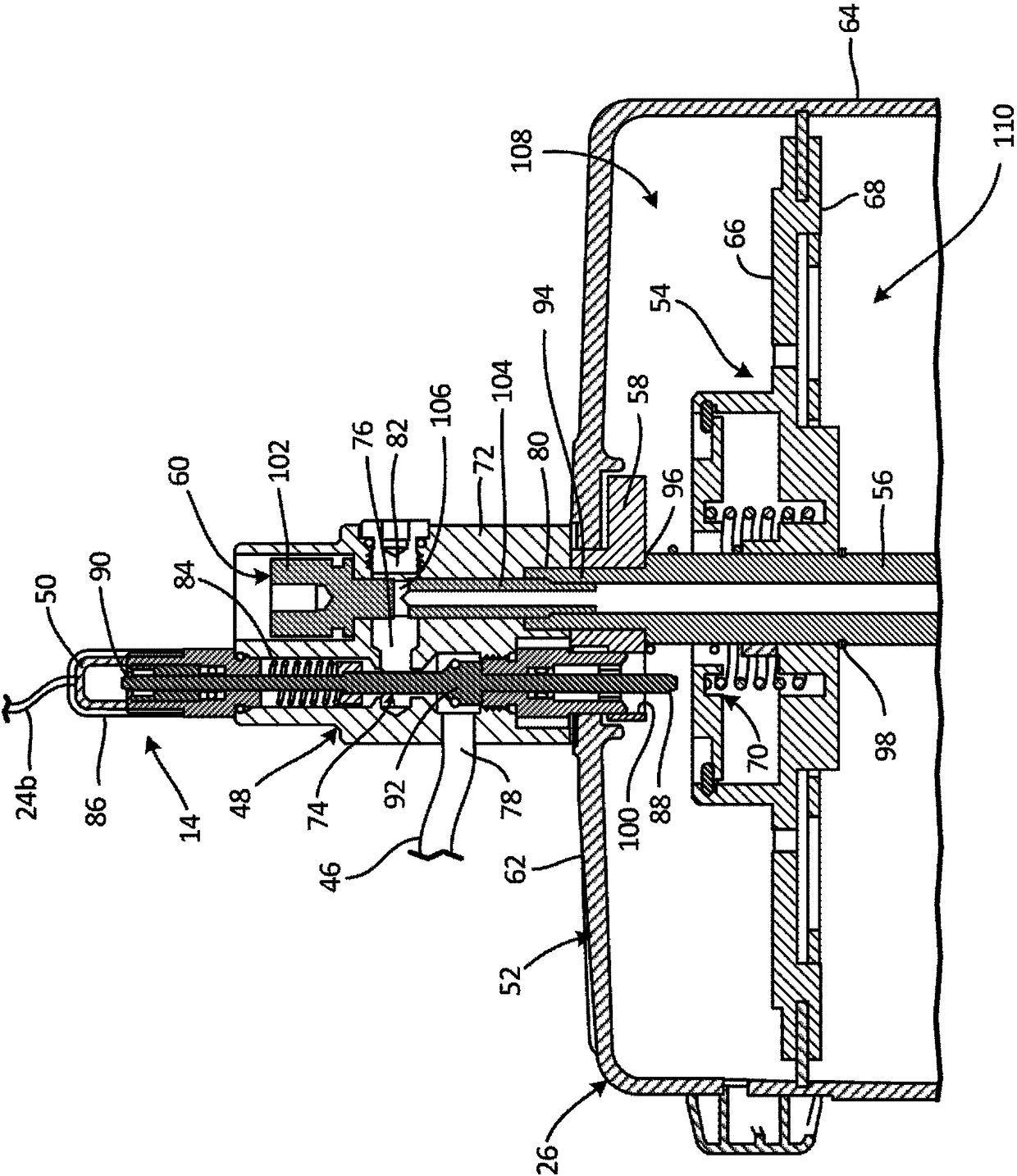

[0014] figure 1 is a schematic block diagram of the lubrication system 10 . Lubrication system 10 includes reservoir assembly 12, high level sensor 14, control system 16, supply line 18, injector 20, notification device 22, and communication links 24a-24d. The reservoir assembly 12 includes a lubricant reservoir 26 and a pump assembly 28 . Lubricant reservoir 26 includes a low level sensor 30 and pump assembly 28 includes a motor 32 and a pump 34 . The pump 34 includes a displacement sensor 36a, and the motor 32 includes a displacement sensor 36b. The control system 16 includes a user interface 38 and a lubricant level estimator 40 . Lubricant level estimator 40 includes processor 42 and memory 44 .

[0015] Lubrication system 10 is a specialized lubrication system for lubricating machinery that includes components such as pumps, pistons, seals, bearings and / or shafts. Lubricant reservoir 26 is mounted on pump assembly 28 . Lubricant reservoir 26 stores lubricant prior t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com