Atomized lubricator controlling and adjusting device and method

A technology of control and regulation, lubricator, applied in the direction of engine level, engine components, engine lubrication, etc., can solve problems such as difficulty in guaranteeing lubricator and limited energy of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

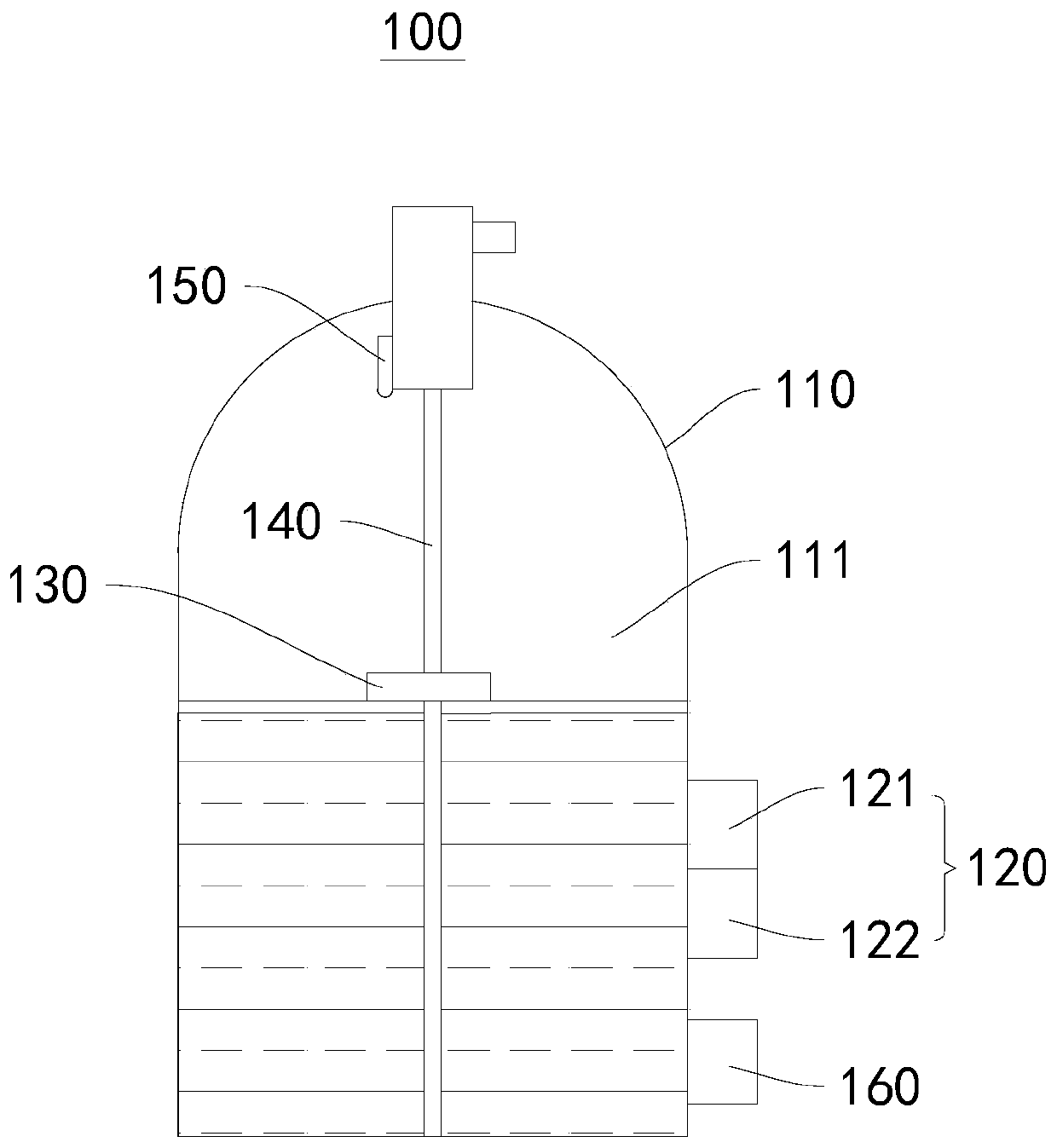

[0037] This embodiment provides a lubricator control and adjustment device 100, please refer to figure 1 , this lubricator control device includes an alarm assembly 120 , a lubricator body 110 , a floater 130 , a distance measuring member 150 and a control member 160 .

[0038] The lubricator body 110 has an accommodating chamber 111 for accommodating oil;

[0039] The floating member 130 is arranged inside the housing chamber 111, and the density of the floating member 130 is lower than that of the oil;

[0040] The distance measuring part 150 is arranged on the lubricator body 110, the distance measuring part 150 and the floating part 130 are arranged oppositely, and the distance measuring part 150 is used to measure whether the height difference between the floating part 130 and the distance measuring part 150 exceeds the preset range;

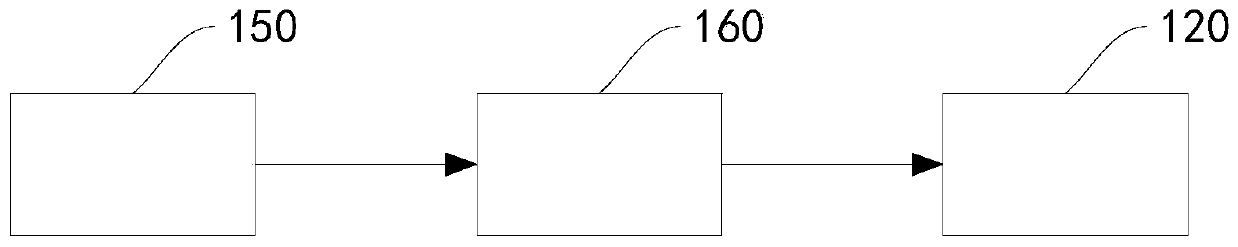

[0041] The control part 160 is respectively connected with the distance measuring part 150 and the alarm assembly 120, and the control pa...

Embodiment 2

[0060] This embodiment provides a method for controlling and adjusting a lubricator, and the method for controlling and adjusting a lubricator includes the following steps:

[0061] Set the preset range of the oil in the lubricator chamber 111 by adjusting the distance measuring member 150;

[0062] Measuring the amount of oil in the oil mist chamber 111 by using the distance measuring member 150;

[0063] When the amount of oil in the lubricator chamber 111 is less than the minimum value of the preset range, the control part 160 controls the alarm component 120 to trigger an alarm;

[0064] When the amount of oil in the chamber of the lubricator is greater than the maximum value of the preset range, the control member 160 controls the alarm component 120 to trigger an alarm.

[0065] When the lubricator control and adjustment method provided in this embodiment is in use, first inject oil into the accommodation chamber 111, the oil in the accommodation chamber 111 is the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com