System for maintaining an aircraft turbine engine

A turbine engine and maintenance system technology, applied in the direction of engine lubrication, machine/engine, engine function, etc., can solve the problems of increasing the manufacturing cost of the oil reservoir and complicated maintenance methods, so as to achieve shortened maintenance operations, simple maintenance procedures, The effect of economic gain is significant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] figure 1 An aircraft, eg an aircraft 2 , is shown having four turbine engines 1 . Aircraft 2 generally comprise an even number of turbine engines 1 , for example two or four. The term turbine engine 1 is known to those skilled in the art. The turbine engine may be, for example, a turbojet or a turboprop. The turbine engine 1 generally includes various components such as a fan, one or more compressors, a cooling circuit, a combustor and one or more turbines.

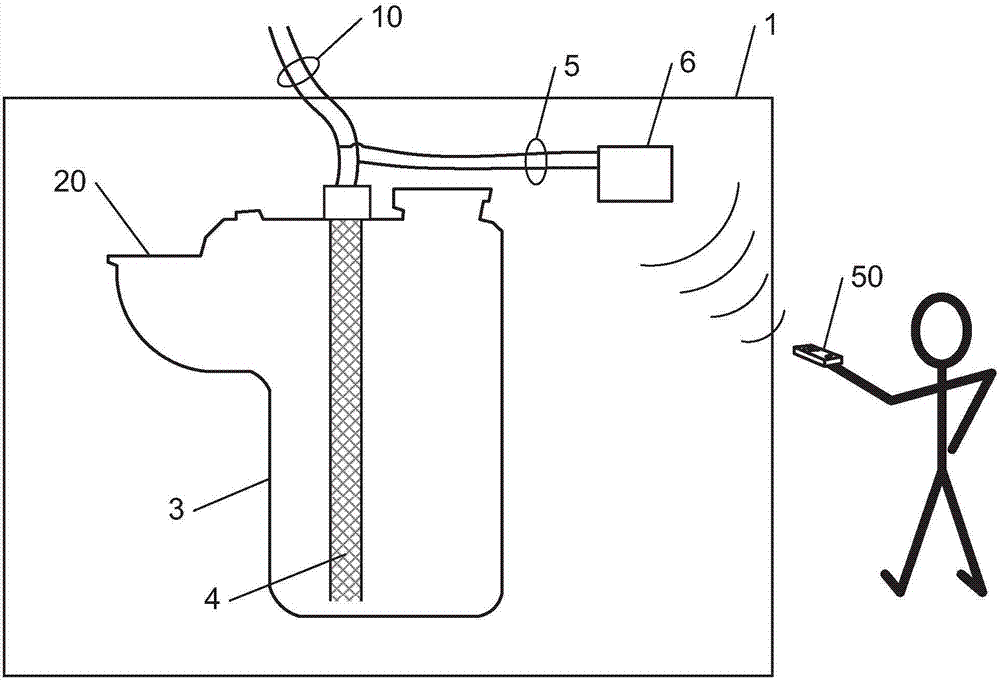

[0046] figure 2 A turbine engine 1 according to the invention, a mobile device 50 and an operator are schematically shown. The turbine engine includes one or more oil reservoirs 3 for providing lubrication to various components. The oil reservoir 3 includes an inlet 20 for supplying oil thereto. The turbine engine 1 according to the invention also comprises a sensor 4 for measuring the oil level in the oil reservoir 3 . Various types of sensors known to those skilled in the art can be used. For example a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com