Stop valve for air conditioner

A shut-off valve and air-conditioning technology, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of complex manufacturing and assembly processes, rebounding on people, complex adjustment and maintenance, etc., to reduce manufacturing costs, eliminate airflow congestion, beneficial to long-term development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]

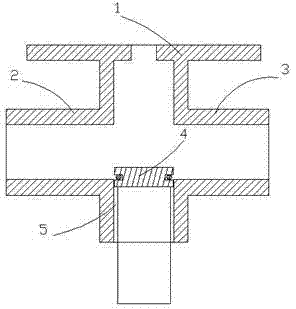

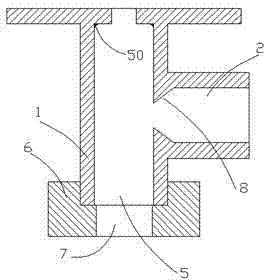

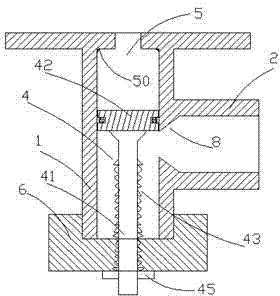

[0049] Such as Figure 2 to Figure 8 As shown, the present invention relates to a shut-off valve for air conditioning, comprising a valve body 1 with a joint hole 2 and a valve core 4, the valve core 4 includes a valve stem 41 and a piston 42 arranged at the end of the valve stem 41, which It is characterized in that: a bonnet 6 is provided at the port of the main hole 5 of the valve body 1, and a through hole 7 with an internal thread is formed on the bonnet 6, and the through hole 7 and the external thread 43 on the outside of the valve stem 41 can realize up and down The rotary joint is connected, and a tapered hole 8 is formed at the inner end of the joint hole 2 close to the valve body 1.

[0050] Further preferably, an inner chamfer 50 is formed around the bottom of the main hole 5 of the valve body 1 , and the inner chamfer 50 collides with the top edge of the piston 42 to form a hard seal.

[0051] Such as Figure 4 The outer surface formed at the connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com