Patents

Literature

46results about How to "Large working radius" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-soil mixed fiber spray-seeding auxiliary material for vegetation restoration, spray-seeding material and construction method of vegetation restoration

InactiveCN107382608ASimple processEasy to operateAnimal corpse fertilisersExcrement fertilisersFiberControlled release

The invention belongs to the technical field of slope ecological restoration, and particularly discloses a non-soil mixed fiber spray-seeding auxiliary material for vegetation restoration, a spray-seeding material, and a construction method of the vegetation restoration. The non-soil mixed fiber spray-seeding auxiliary material for the vegetation restoration comprises the following components in parts by weight: 300-500 parts of wood fiber, 10-20 parts of mechanical fiber, 5-10 parts of organic tackifier, 150-500 parts of organic fertilizer, 150-300 parts of peat, 150-300 parts of coconut shred fiber, 0-10 parts of controlled-release fertilizer, 15-30 parts of compound fertilizer, 8-15 parts of water retention agent, 3-10 parts of binding agent and 5-10 parts of microbial fermentation agent.

Owner:北京华夏绿洲生态环境工程有限公司

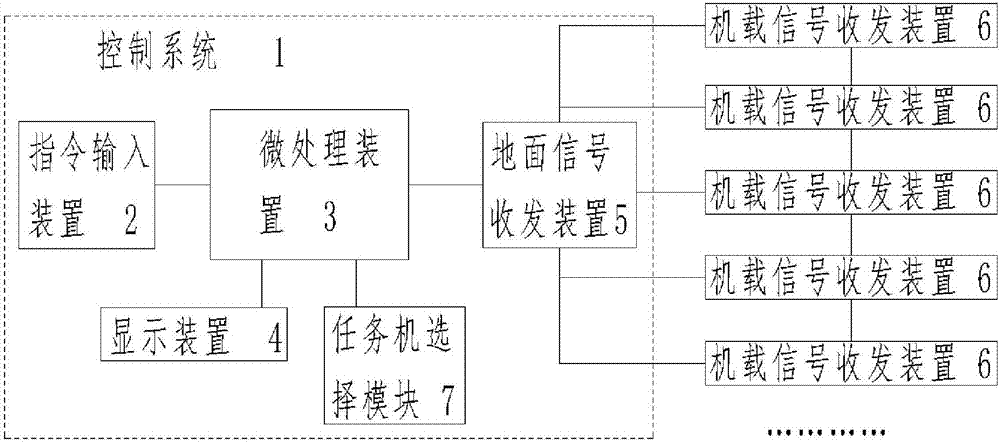

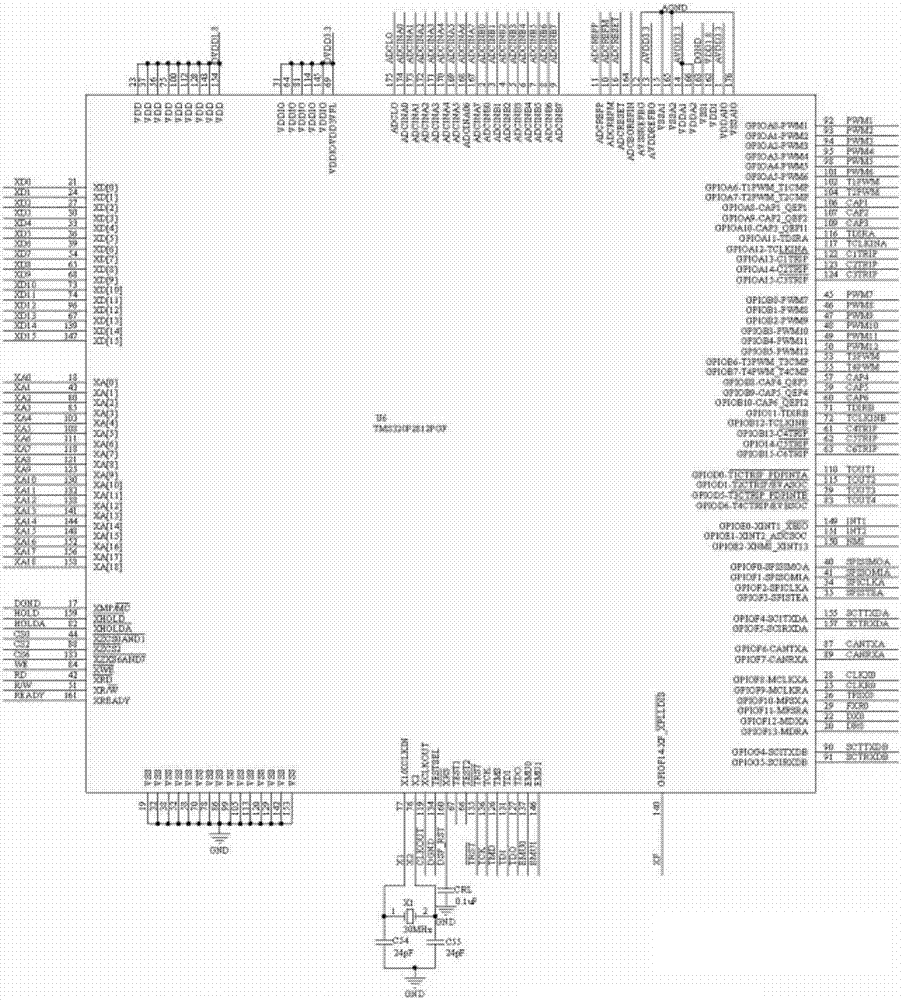

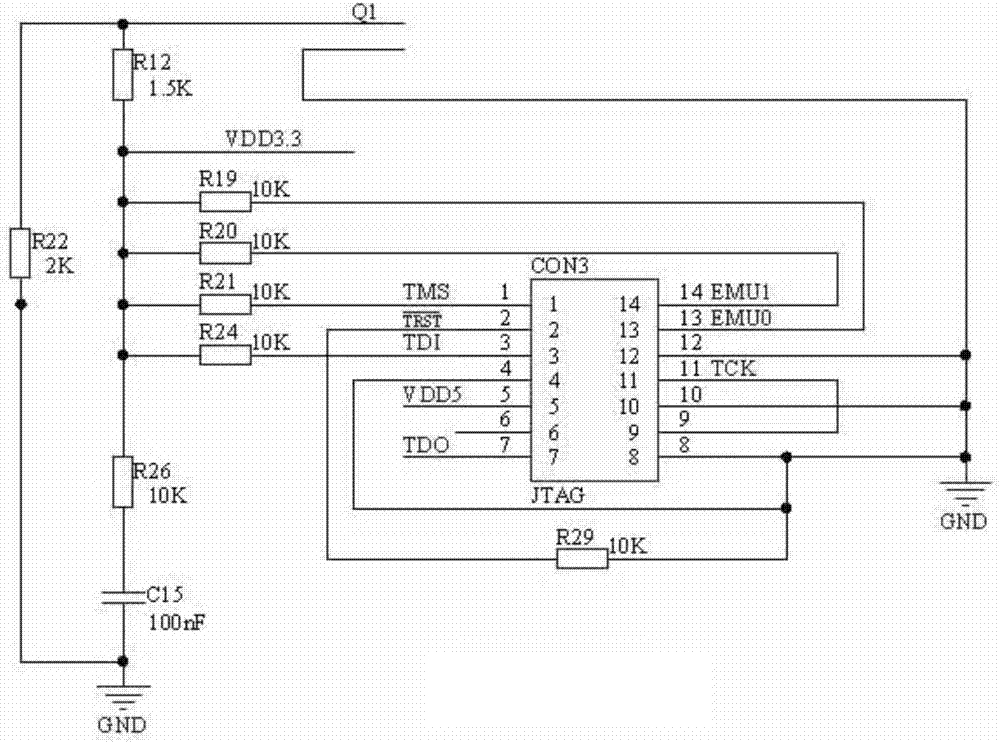

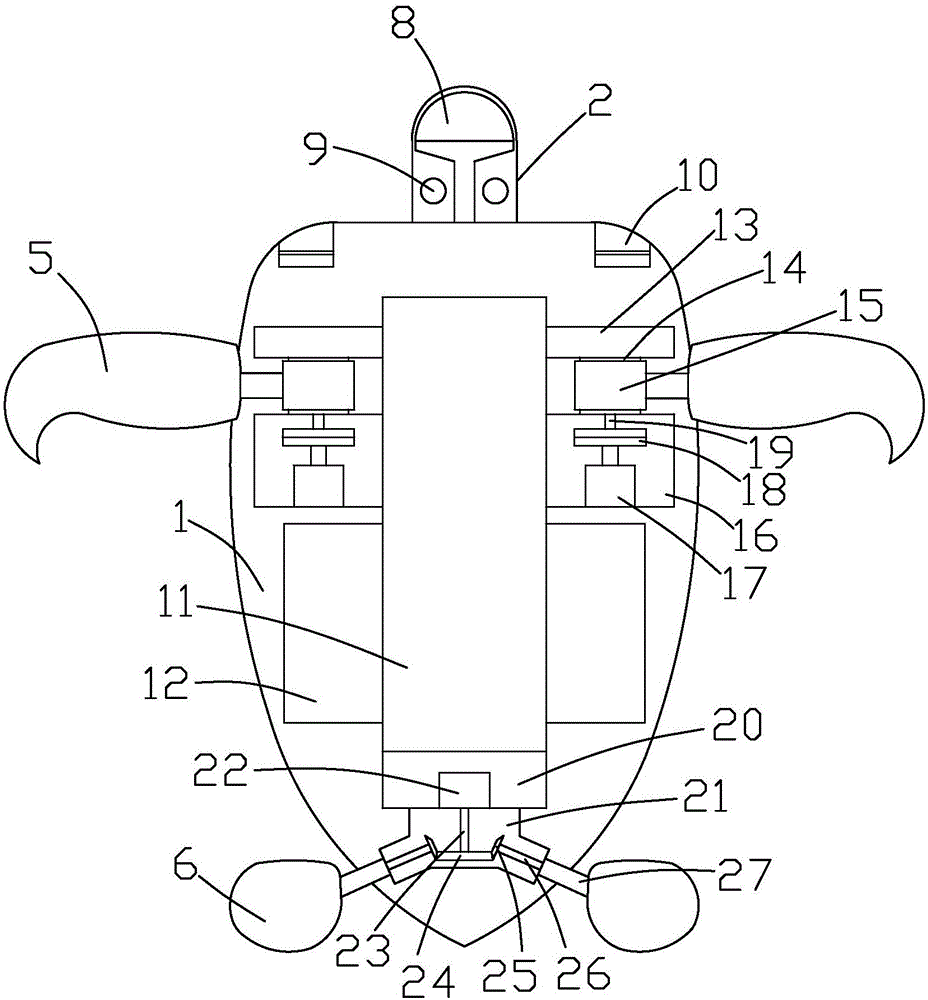

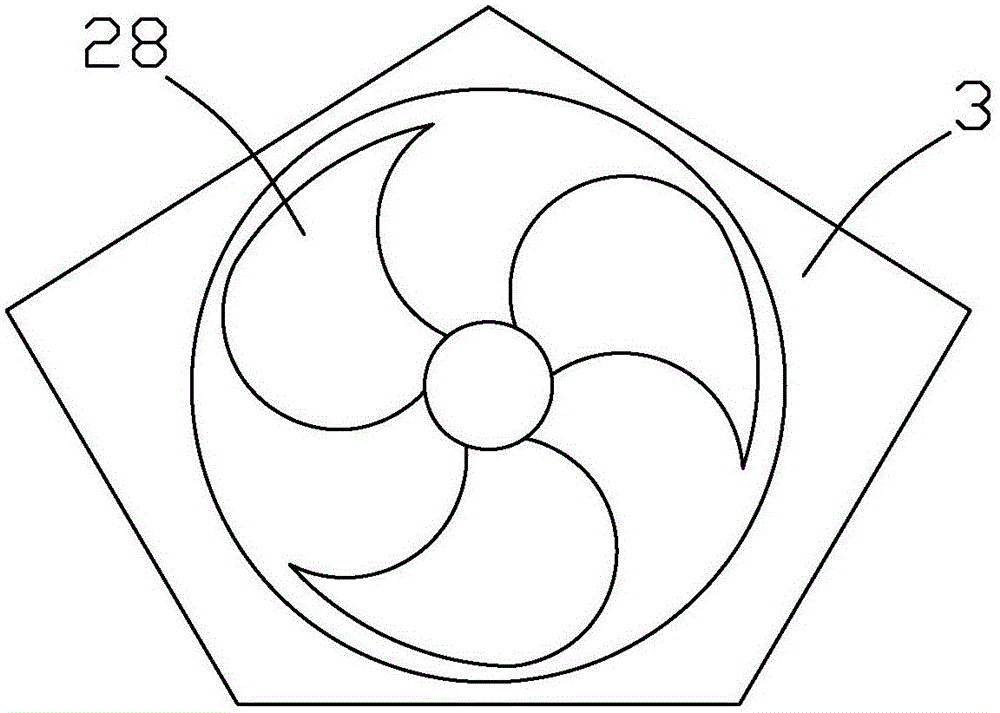

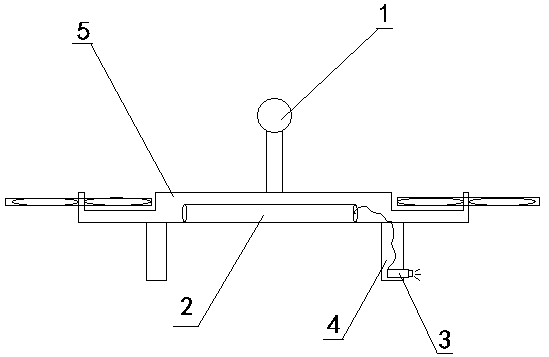

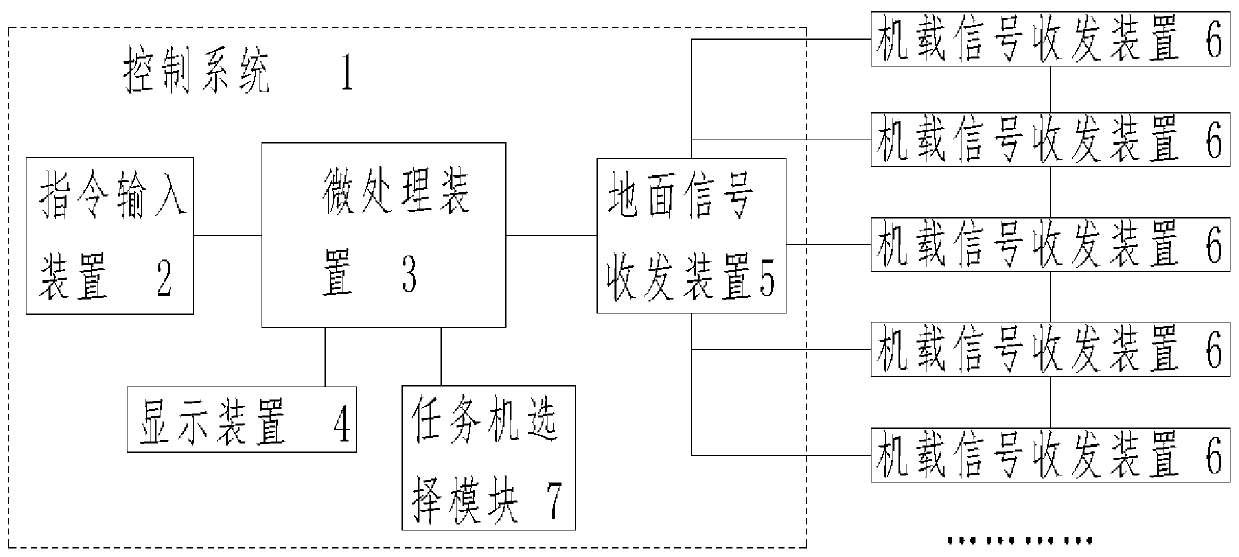

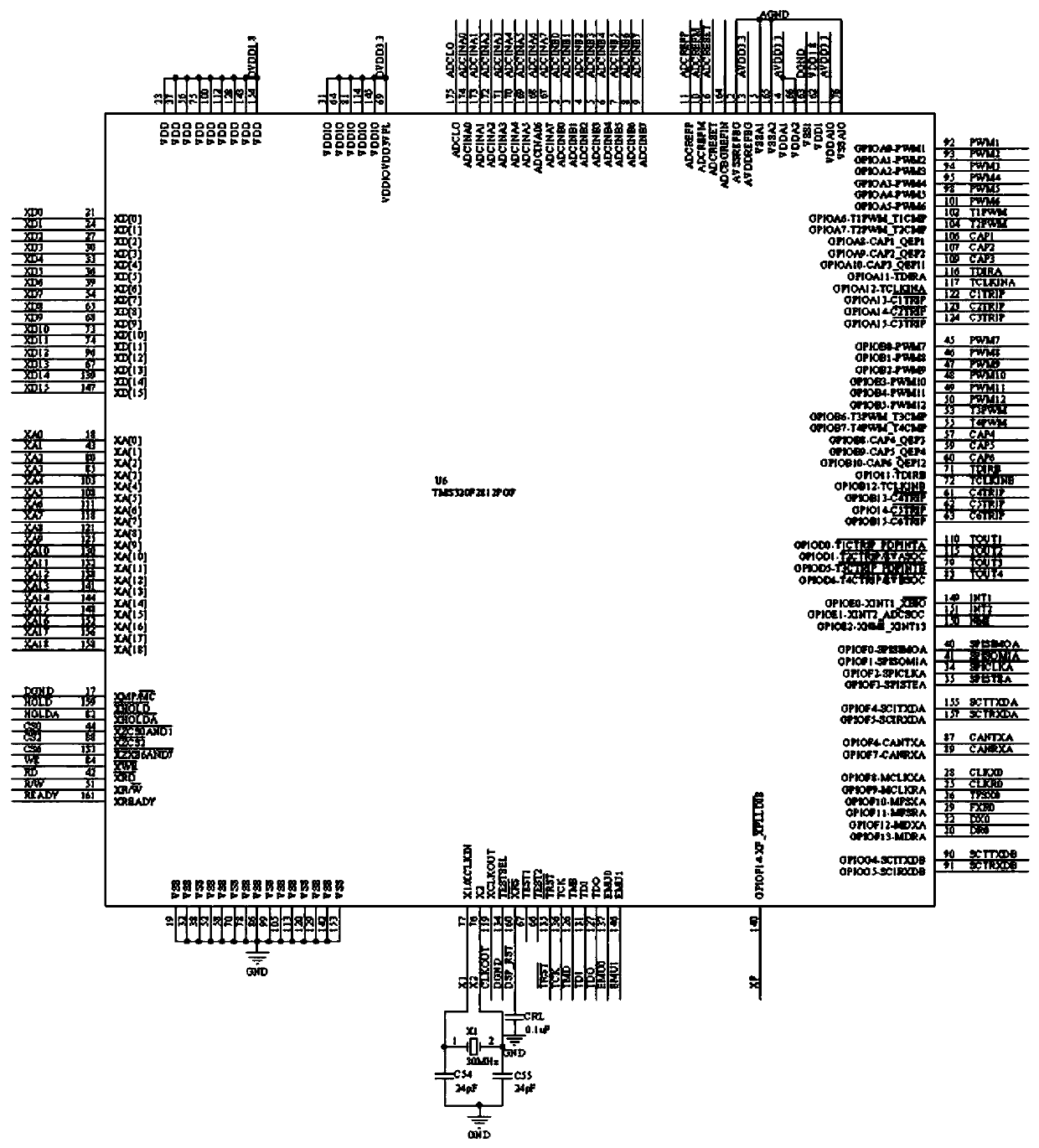

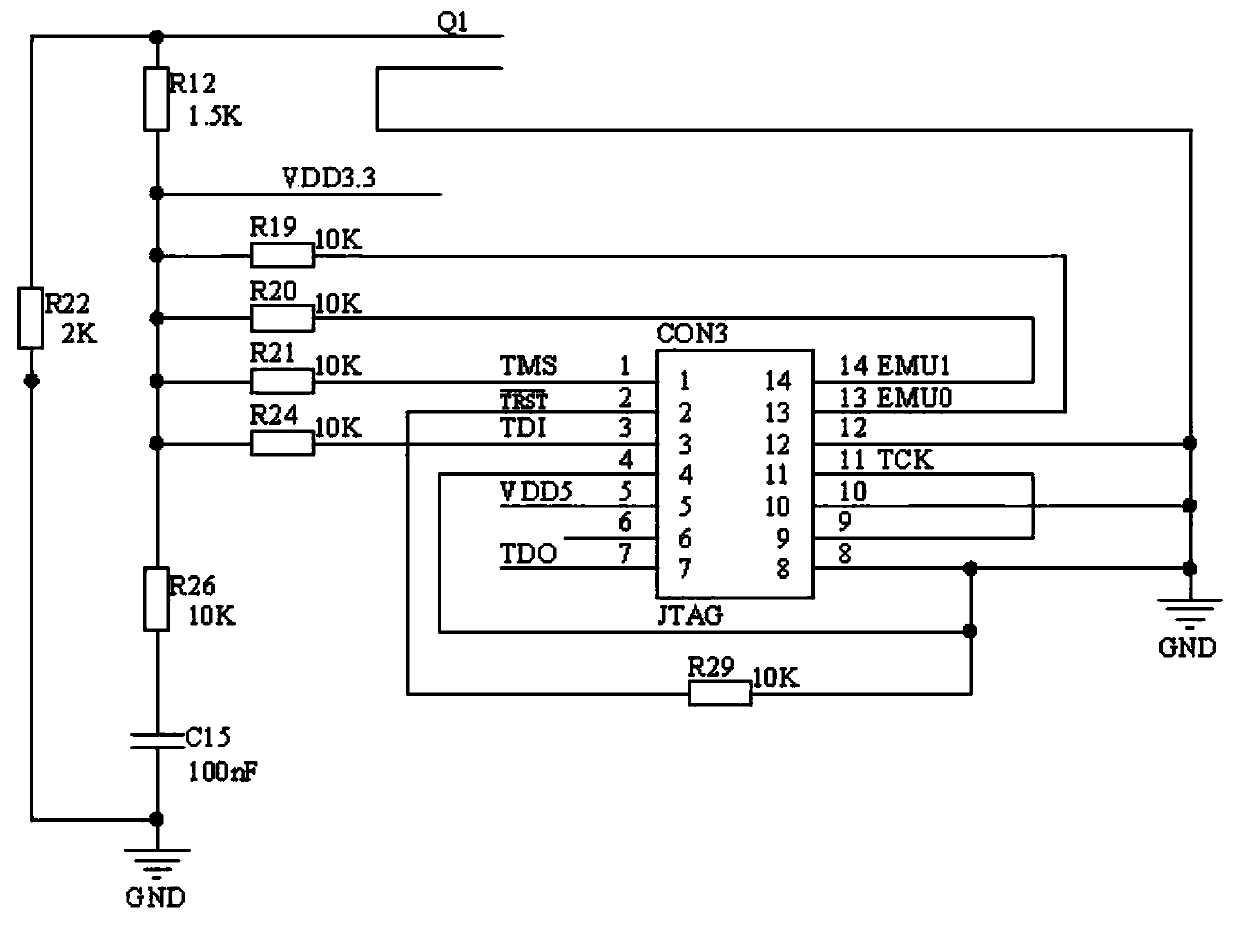

Uniformly controlled multifunctional unmanned aerial vehicle group

ActiveCN106919183ALarge working radiusImprove battery lifePosition/course control in three dimensionsData informationUncrewed vehicle

The invention discloses a uniformly controlled multifunctional unmanned aerial vehicle group. The unmanned aerial vehicle group is provided with a plurality of unmanned aerial vehicles, and is characterized in that the unmanned aerial vehicles carry different working devices, so that different unmanned aerial vehicles can be selected when different tasks are executed. Each unmanned aerial vehicle carries a small number of working devices and is low in cost, so that the economic loss is within a controllable range even if the unmanned aerial vehicle runs into an accident and is damaged. In addition, data information is transferred through a ZigBee wireless module, and a plurality of ZigBee wireless modules form a network. The plurality of unmanned aerial vehicles are controlled by using a single device through a data transmission module, so that the manpower and material resource cost brought about by controlling a plurality of unmanned aerial vehicles is saved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

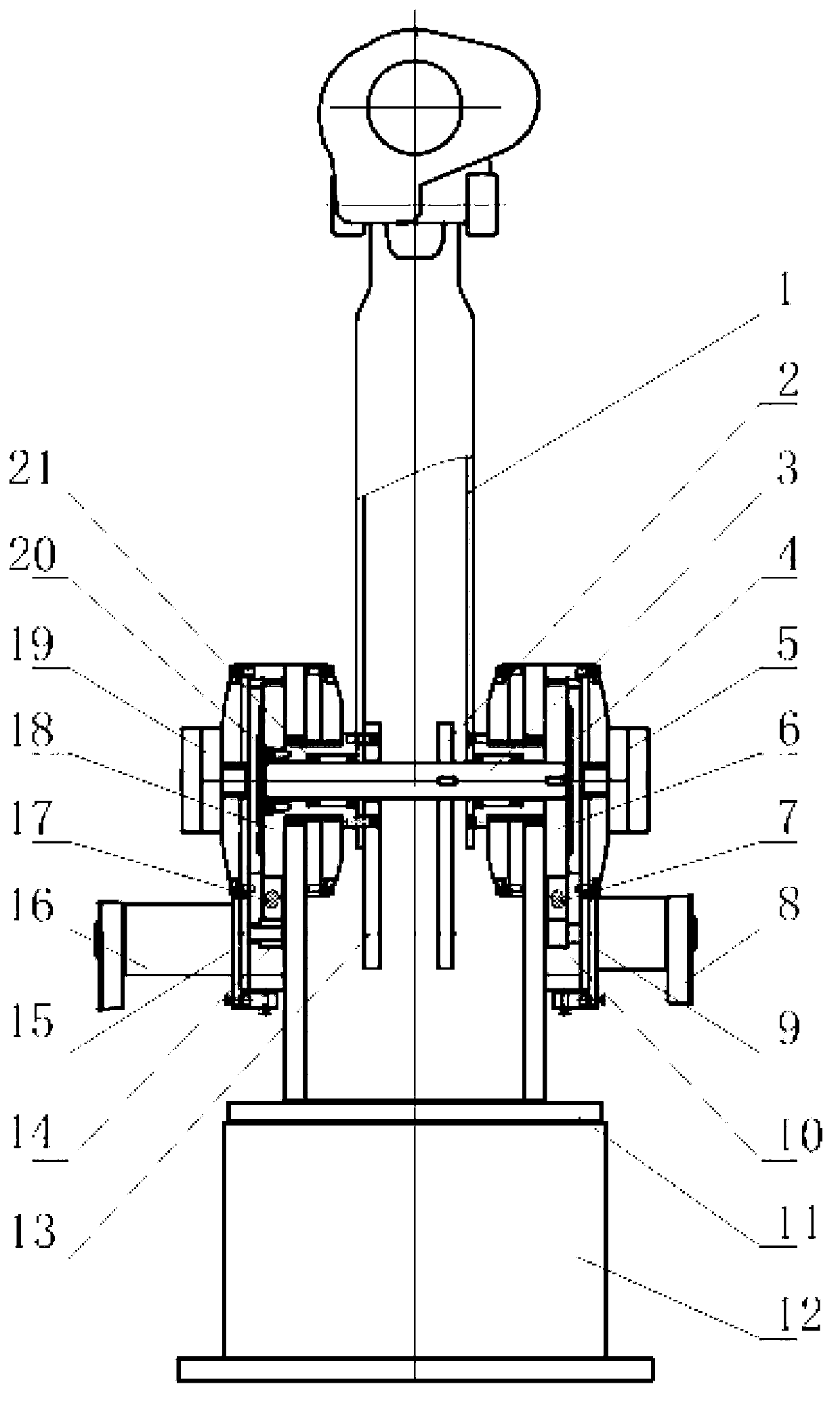

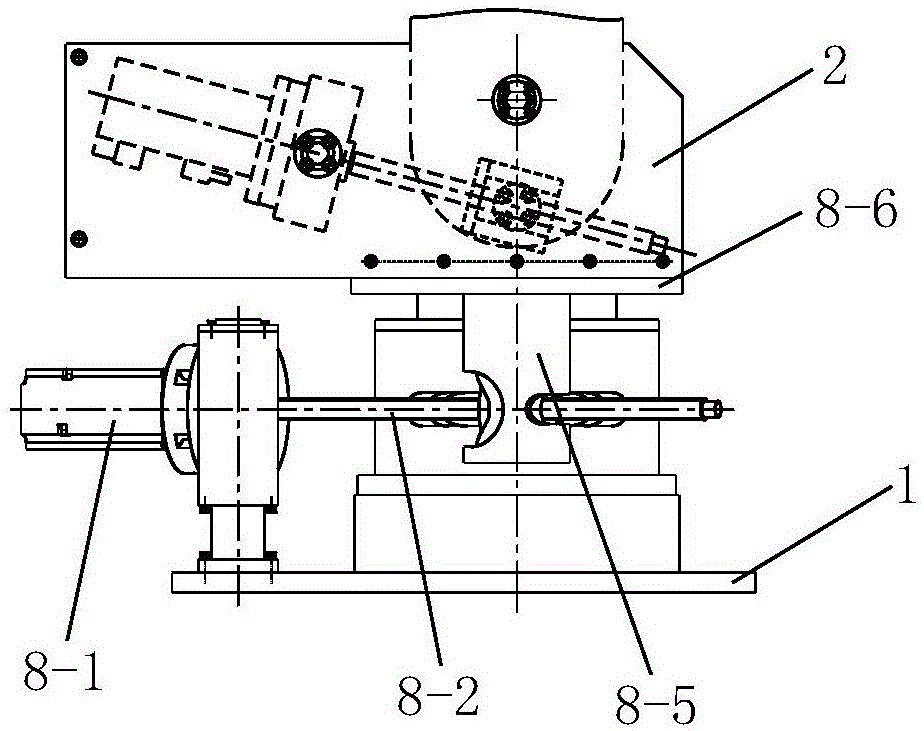

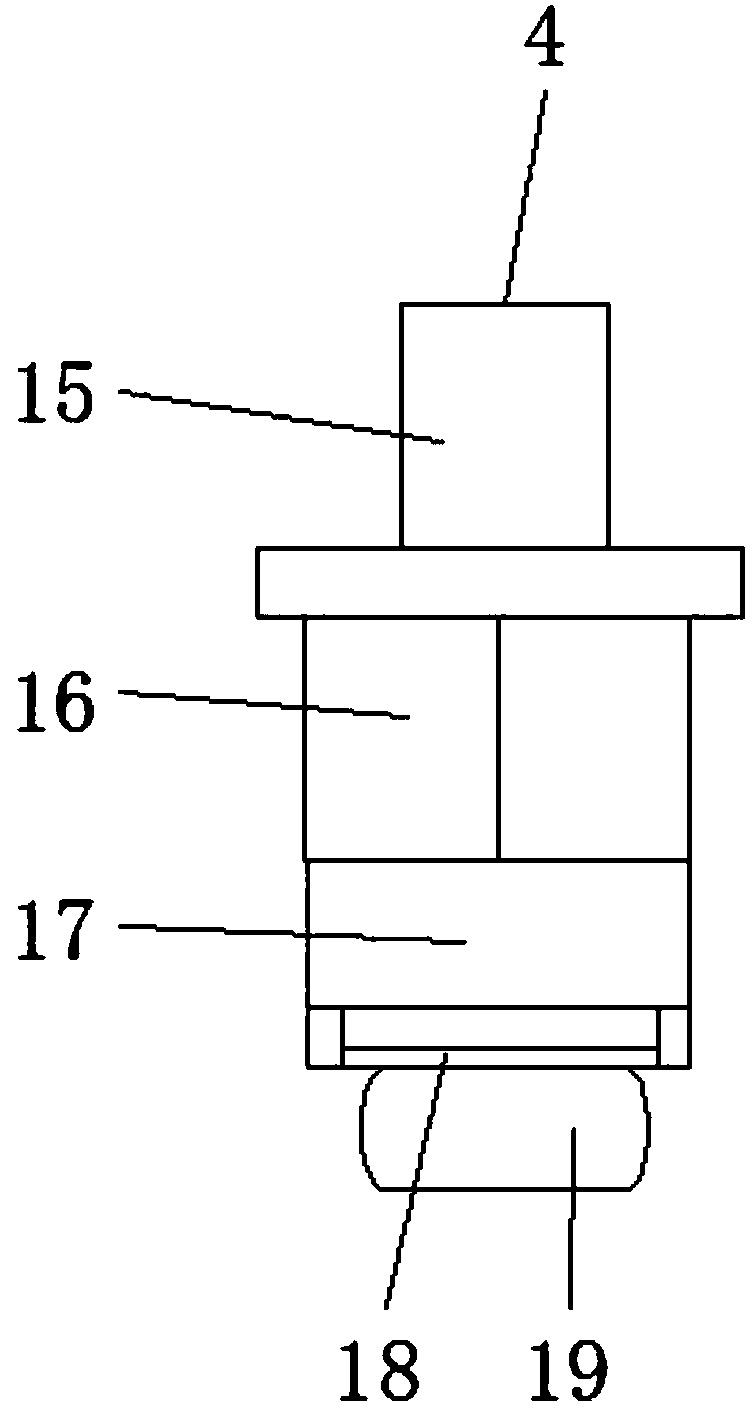

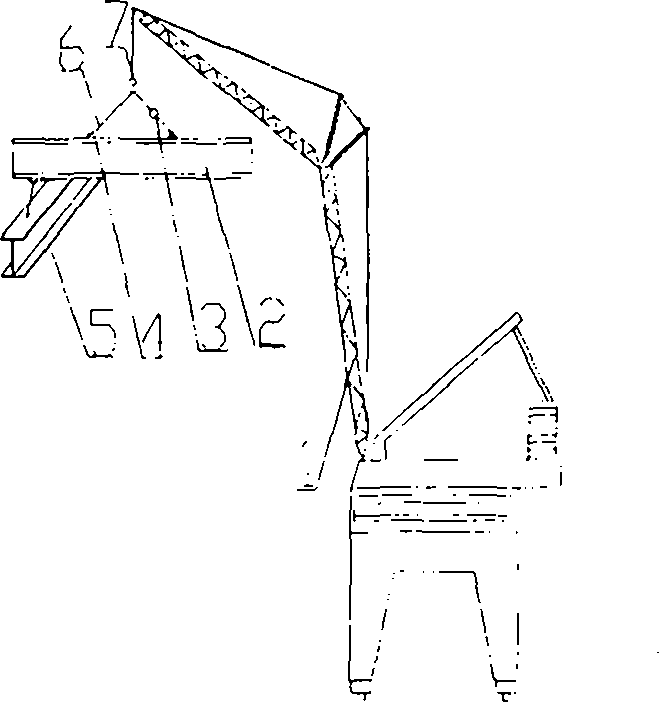

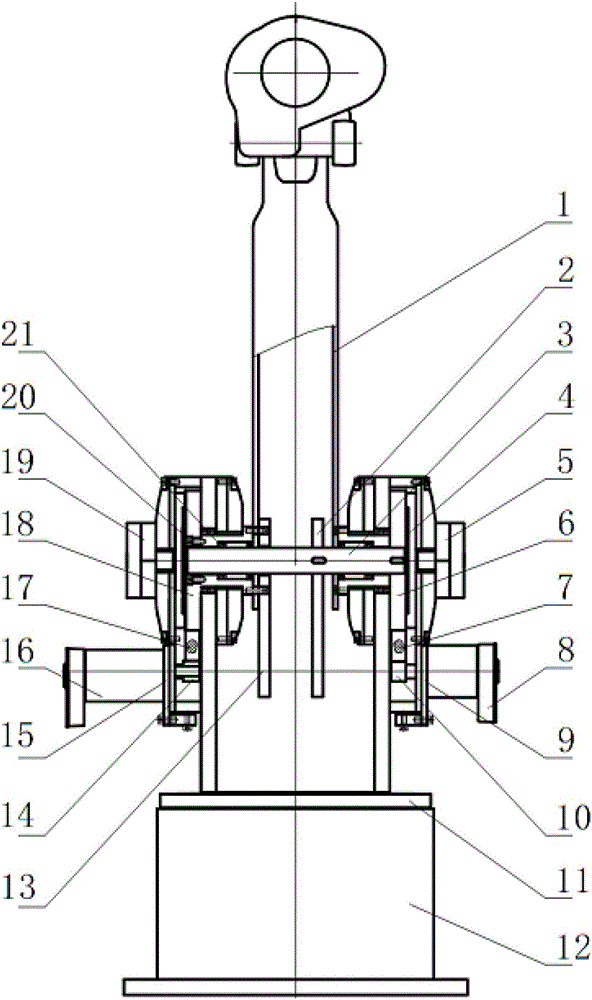

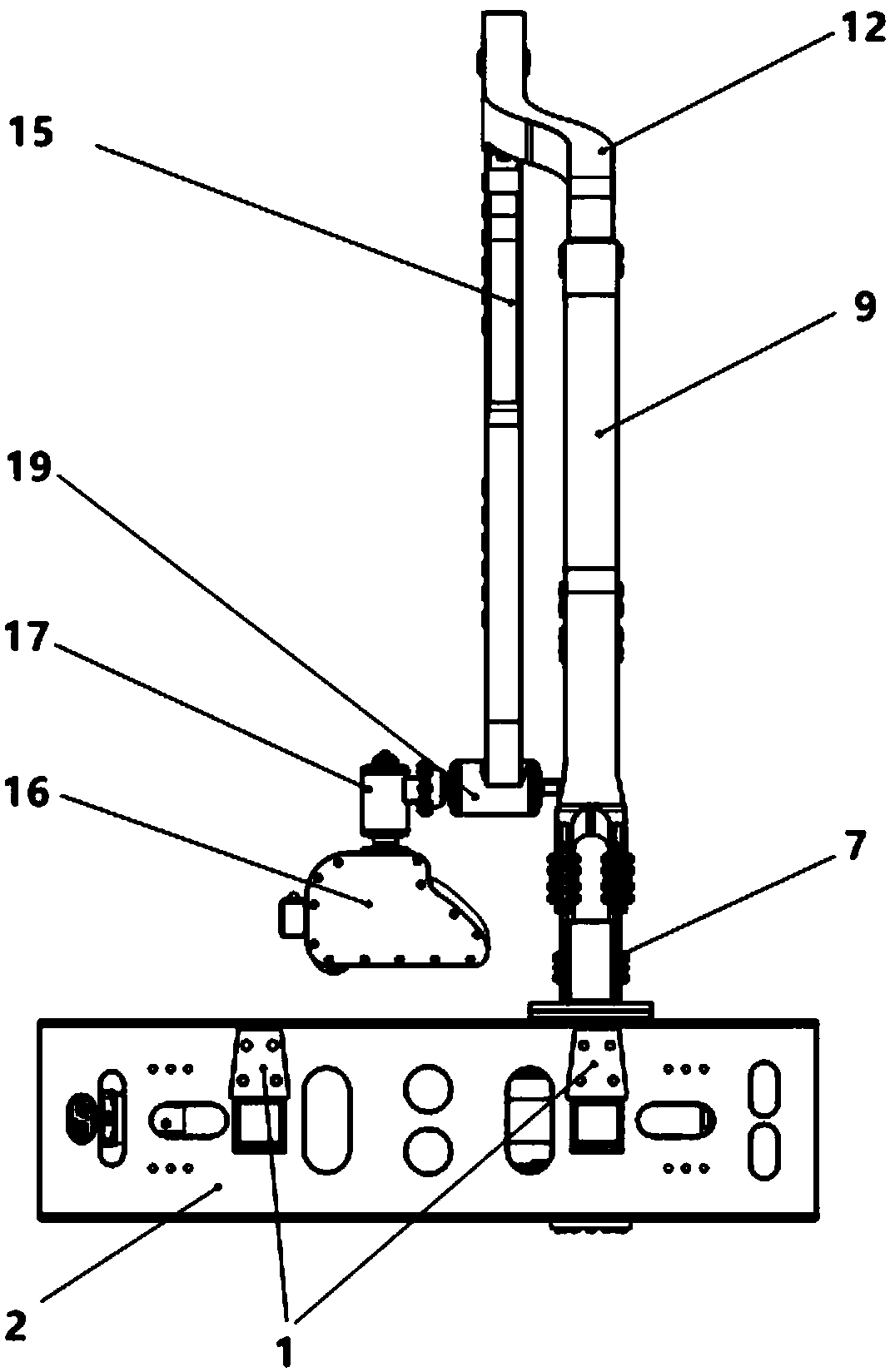

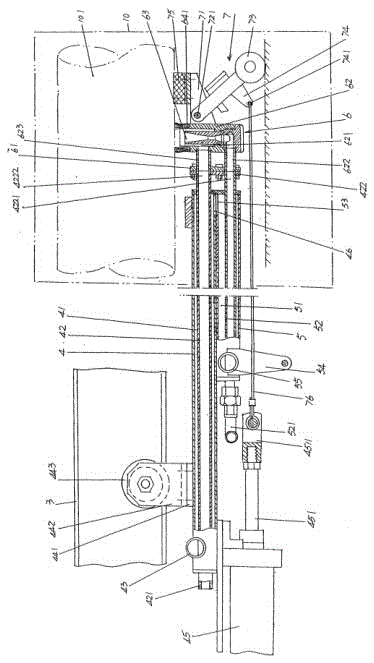

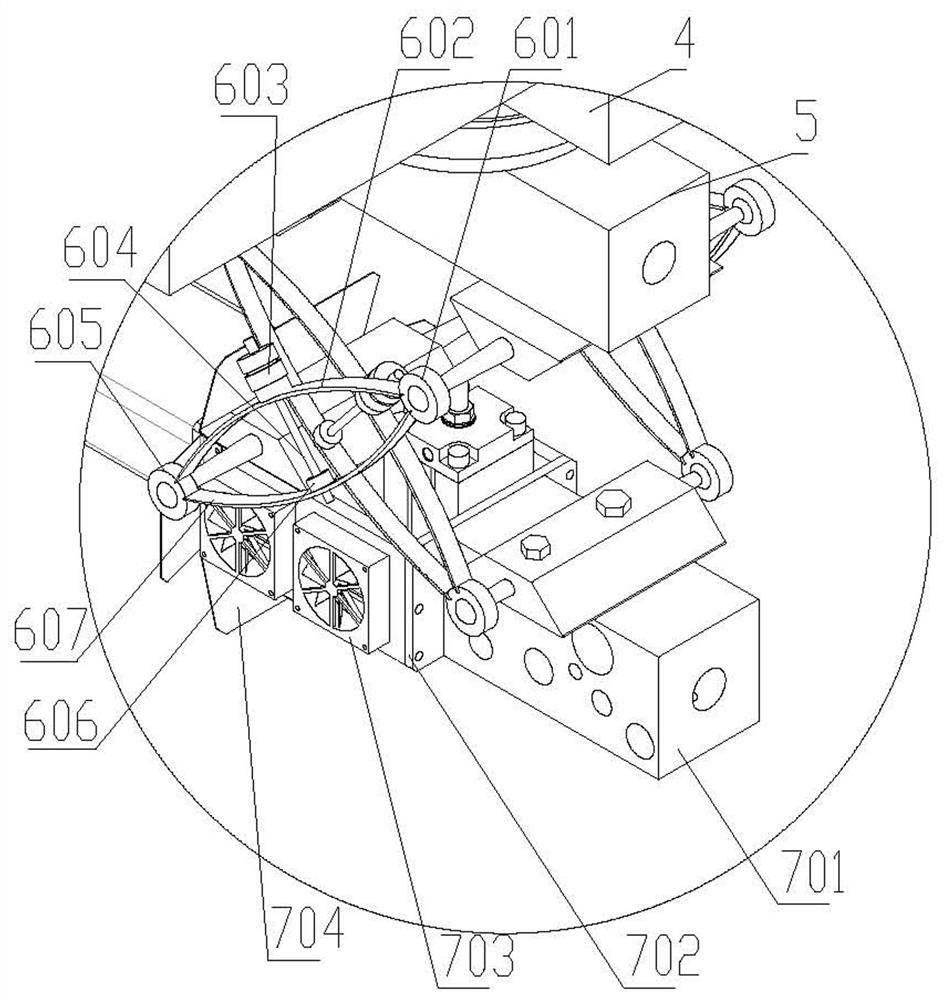

Nuclear power steam generator pipe detection robot

InactiveCN101364452AEasy accessLower requirementNuclear energy generationNuclear monitoringNuclear powerDrive shaft

The invention provides a pipeline inspection robot for a nuclear steam generator, which comprises two pawing mechanisms hinged with an upper cantilever via a driving shaft and a lower cantilever via a driven shaft. The upper cantilever is composed of two segments which are hinged with each other via a driving shaft; the lower cantilever is composed of two segments which are hinged with each other via a driven shaft; a motor is connected with the lower ends of both the driving shaft between the upper cantilever and the two pawing mechanisms and the driving shaft between the two segments of the upper cantilever; and a potentiometer is arranged at the upper end of each driving shaft and is connected with a sensor guide arm which is hinged with a fixed column fixed on the upper cantilever. The pipeline inspection robot has the following advantages: small volume, so as to be easy to be put into the steam generator by an operator through a narrow manhole; convenient energy availability, and flexible and reliable control; cantilever structure with a relatively large working radius after being unfolded; low requirements for the motor, and reliable operation; and good adaptability of replacement parts to different apertures and aperture plates.

Owner:HARBIN ENG UNIV

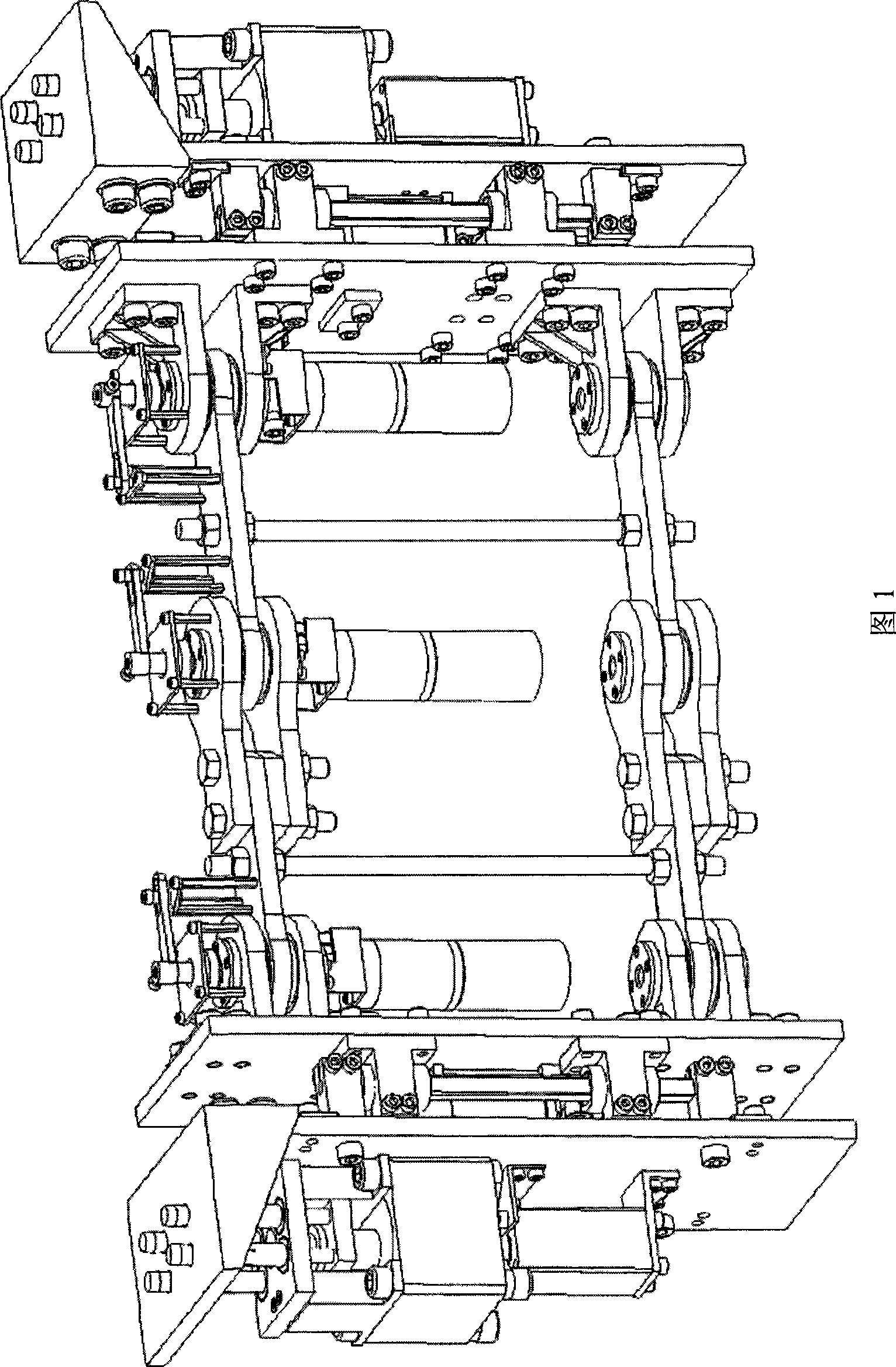

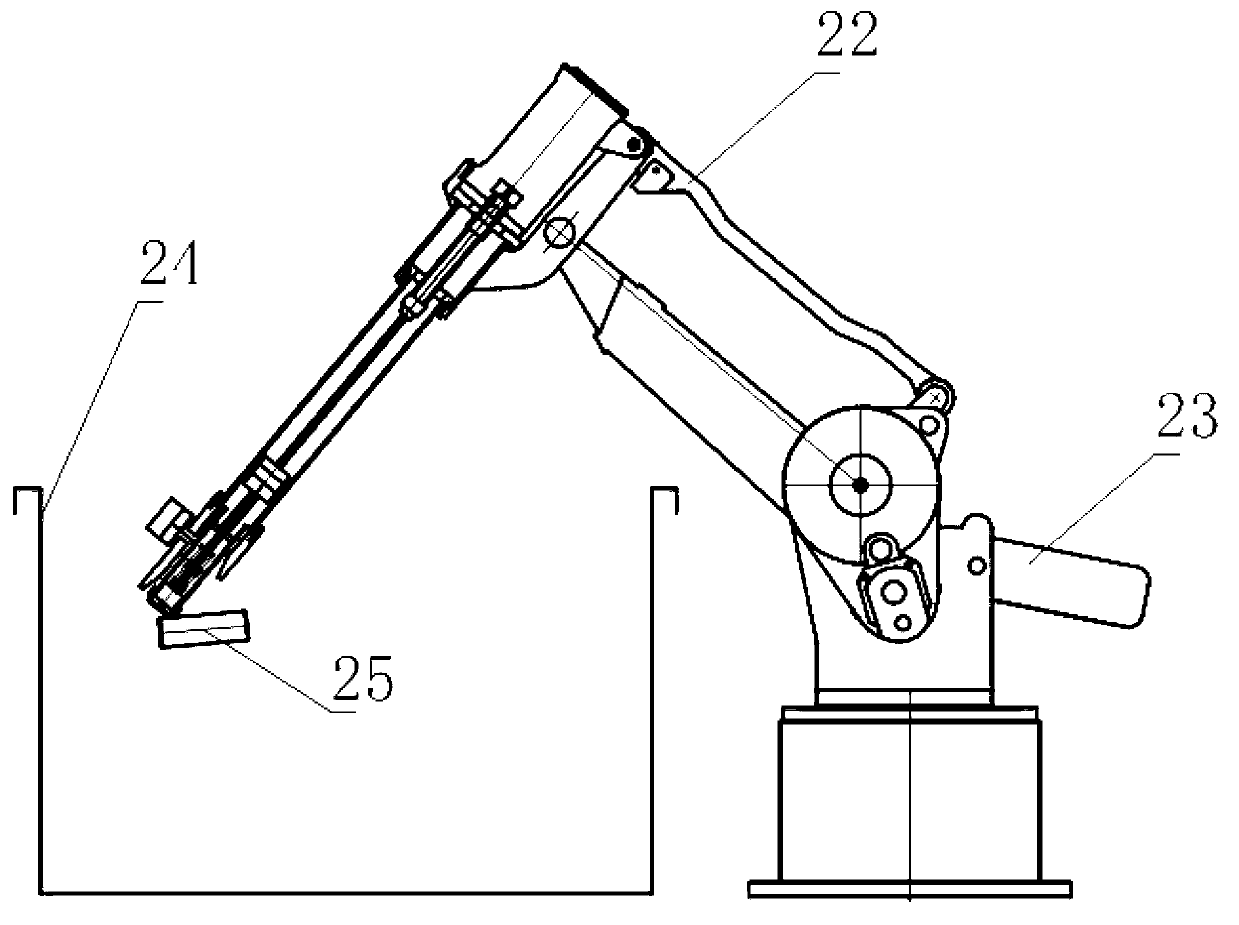

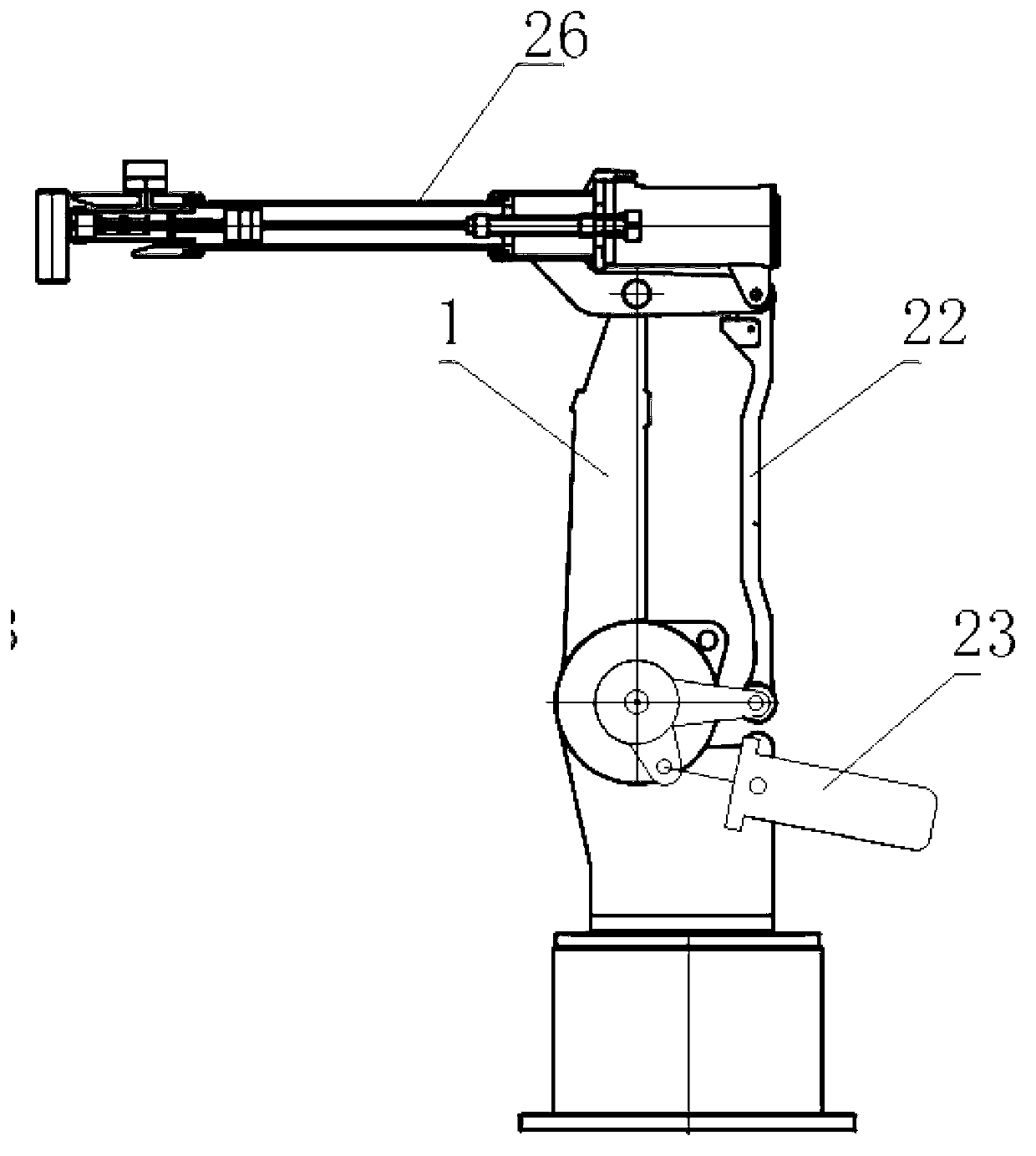

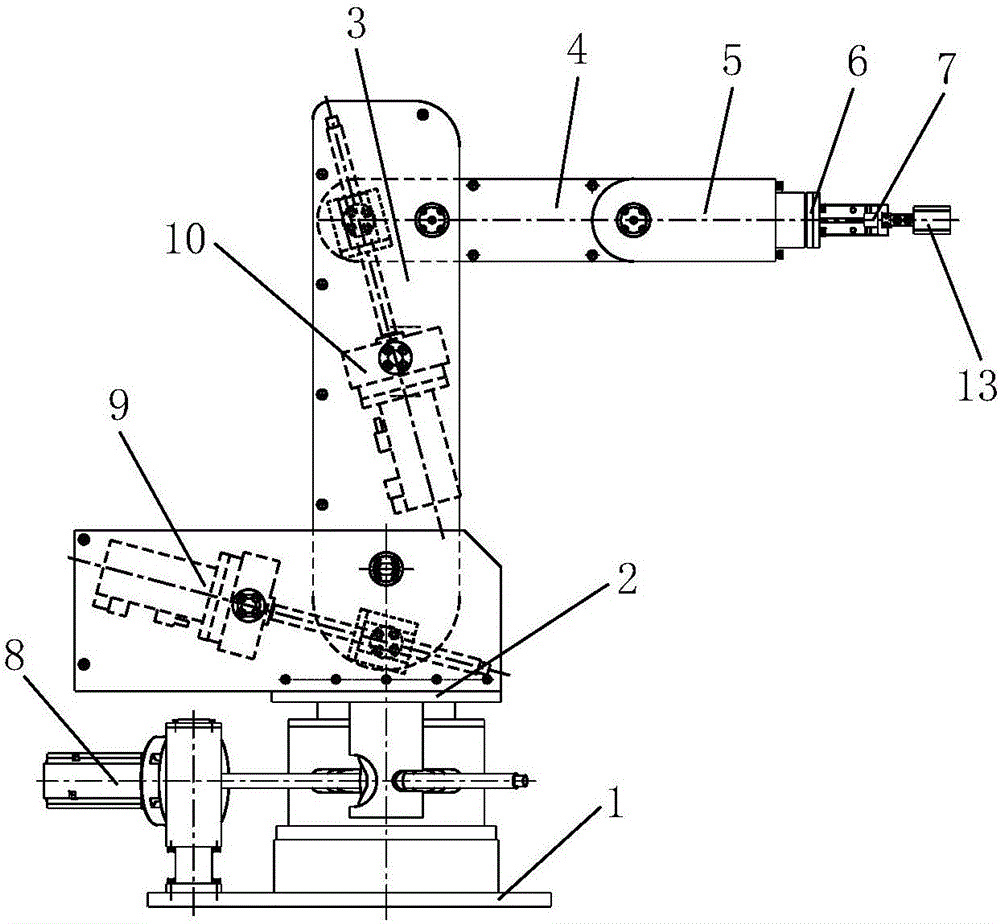

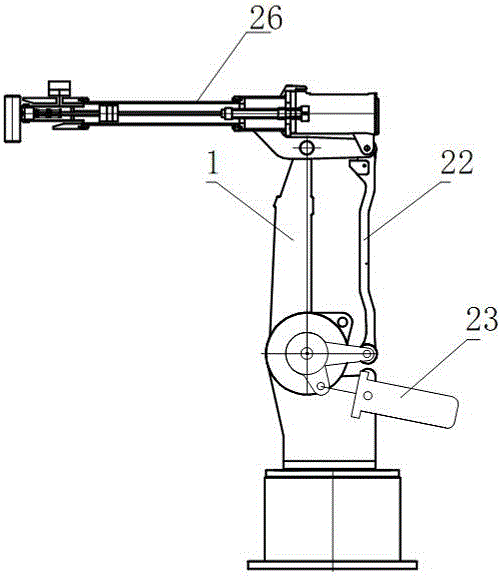

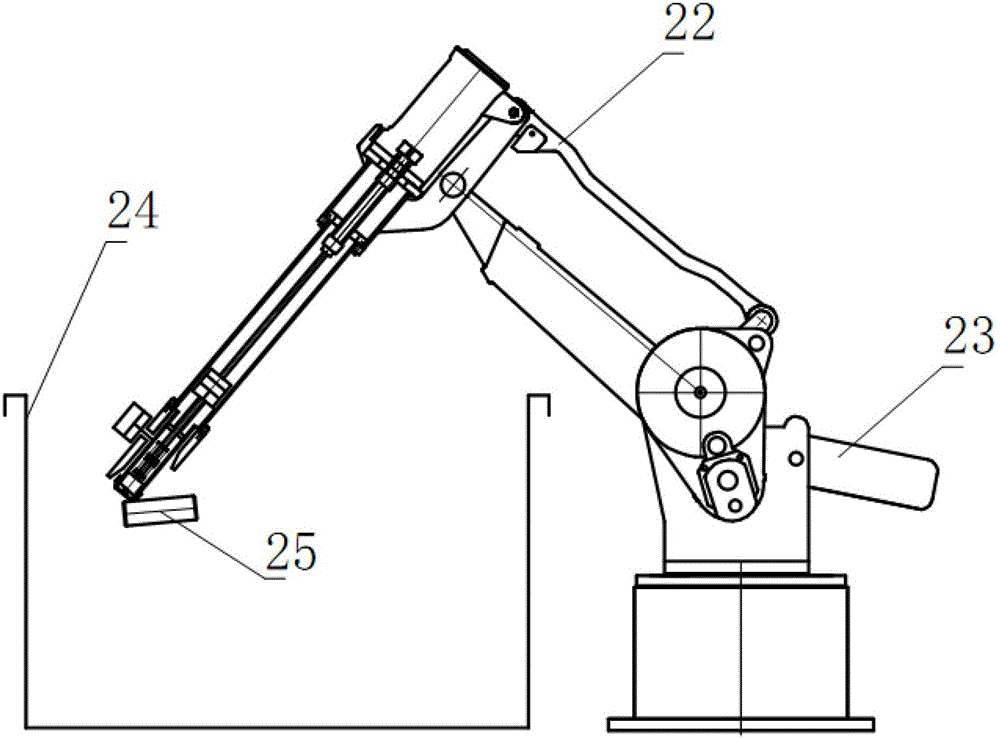

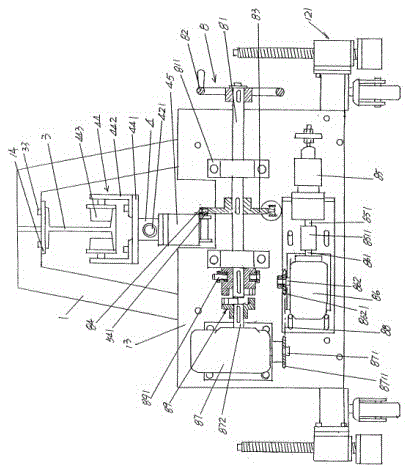

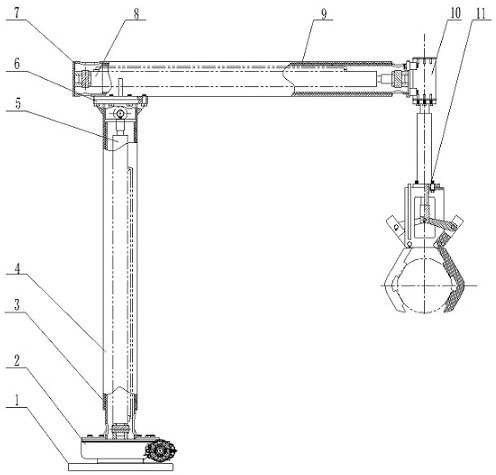

Sorting, clamping and conveying industrial robot applied to forging industry

The invention discloses a sorting, clamping and conveying industrial robot applied to forging industry. The sorting, clamping and conveying industrial robot is characterized by comprising a rotary base, a large arm, a small arm, a material sucking and clamping device, a large arm driving mechanism and a small arm driving mechanism, wherein the large arm is arranged on the rotary base, the small arm is arranged on the head of the large arm, and a workpiece clamping device is arranged on the small arm; and the large arm is driven by the large arm driving mechanism to swing along a large arm transmission shaft, and the small arm is driven by the small arm driving mechanism to swing along a small arm transmission shaft. The sorting, clamping and conveying industrial robot disclosed by the invention, can realize the telescopic swing of the large arm and the small arm, the automatic sorting and the operation of clamping a workpiece into an inlet of a diathermanous furnace through the large arm arranged on the rotary base and the small arm arranged on the large arm, has the advantages of large working radius, high working efficiency, low noise and the like, saves a great amount of labors, has a simple structure, and is reliable in working and lower in manufacturing and maintenance costs.

Owner:钟昀晖

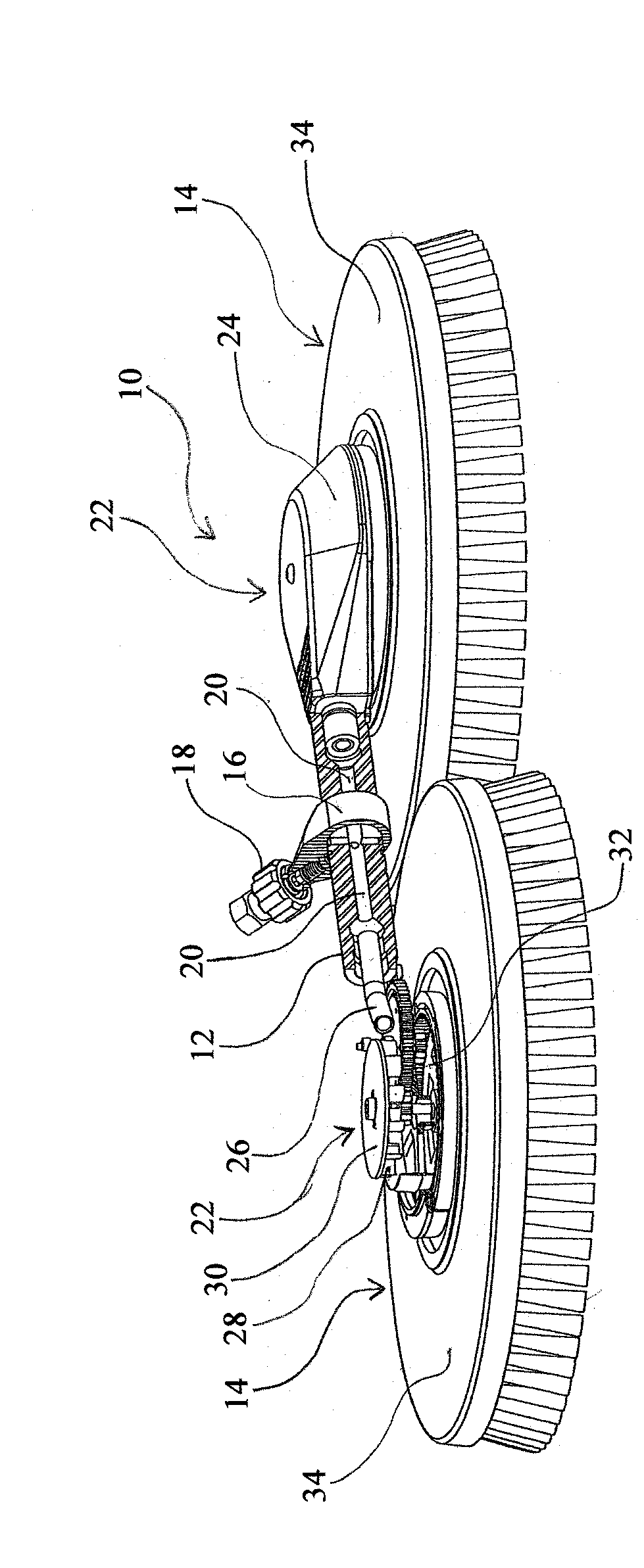

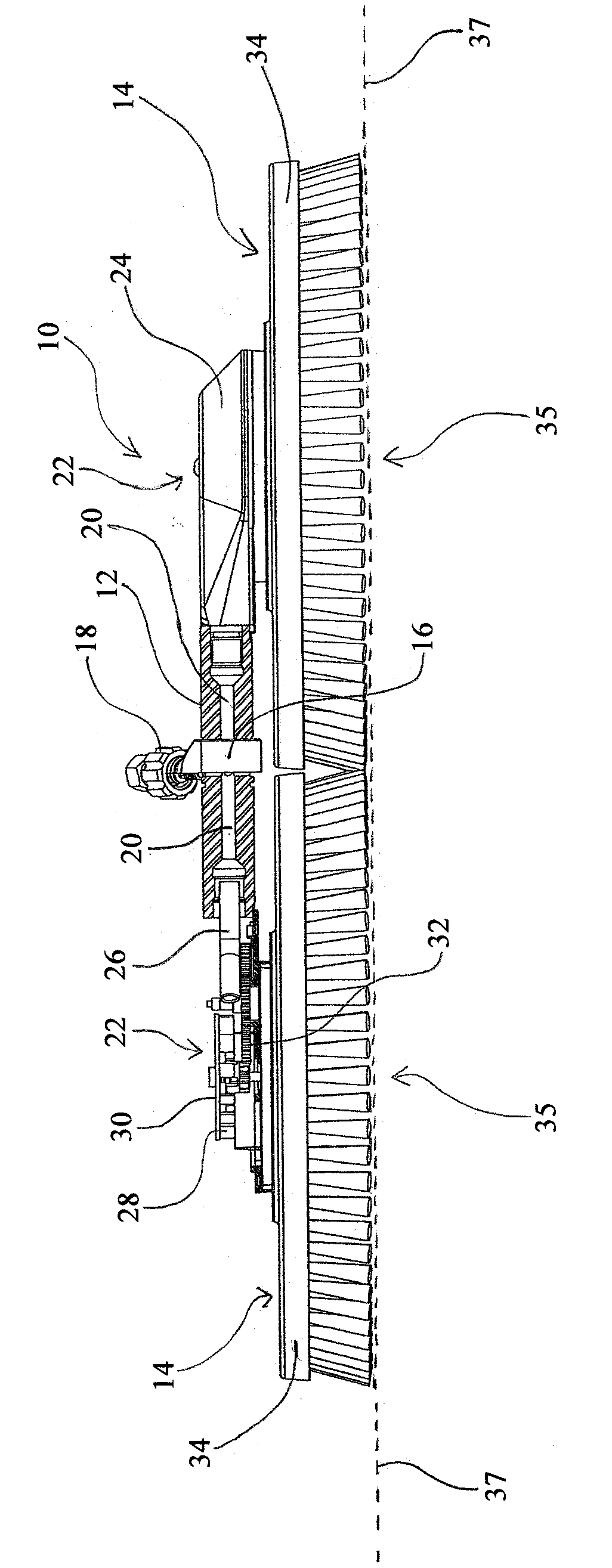

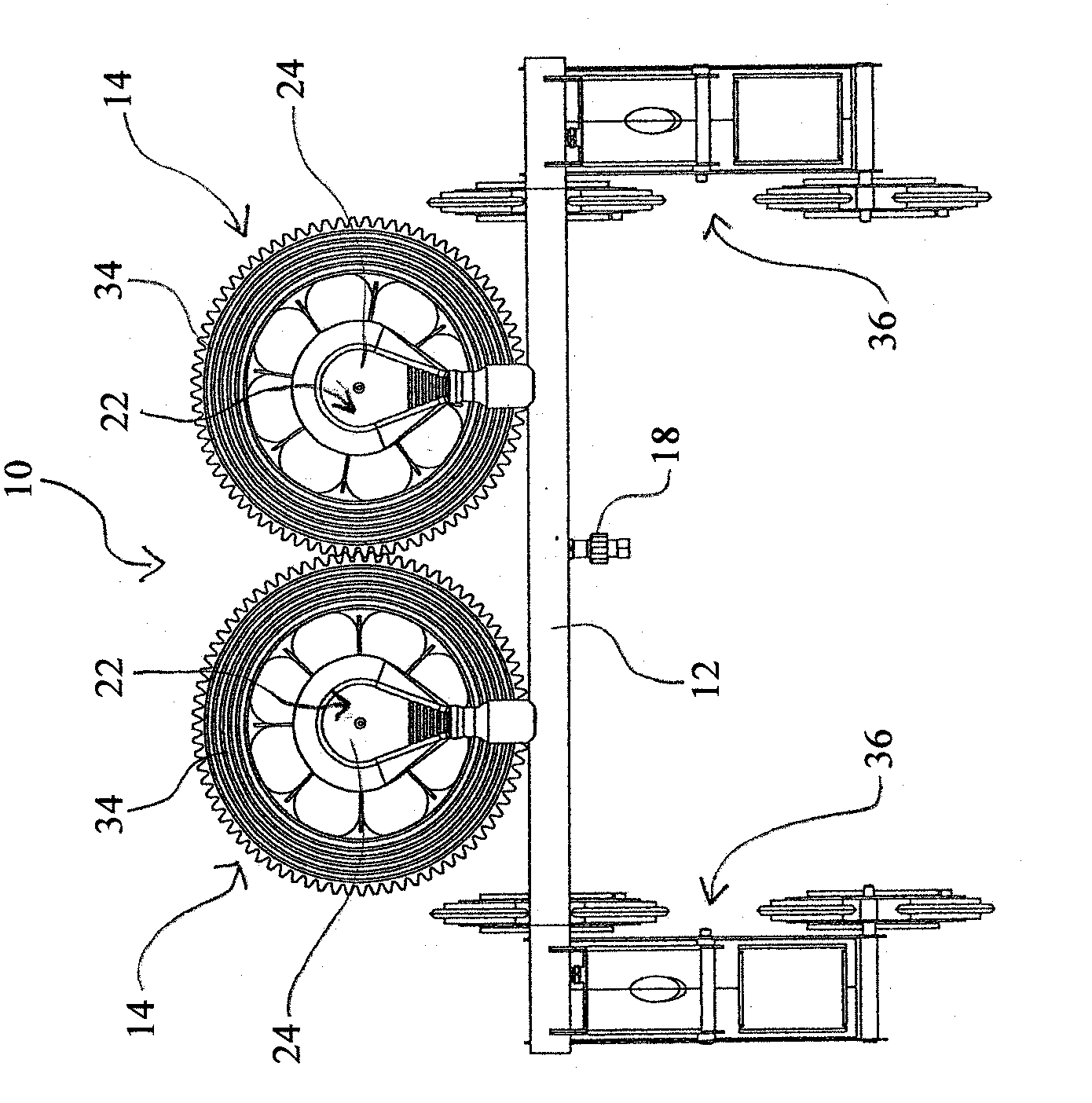

Cleaning device

InactiveCN102836833AFlat designLarge working radiusSolar heating energySolar heat devicesEngineeringSolar energy

The invention relates to a device for cleaning surfaces, especially surfaces of a solar energy device on a roof. The device comprises a bracket and at least two cleaning mechanisms connected with the bracket, wherein the cleaning mechanisms respectively comprise brushes and liquid driving devices for the brushes, the brushes are made to rotate along the axle extending from the working surfaces of the brushes by using the liquid driving devices, the cleaning mechanisms are arranged on the bracket in a way that a common working surface is at least basically defined on the working surfaces of the brushes.

Owner:安东·耶格

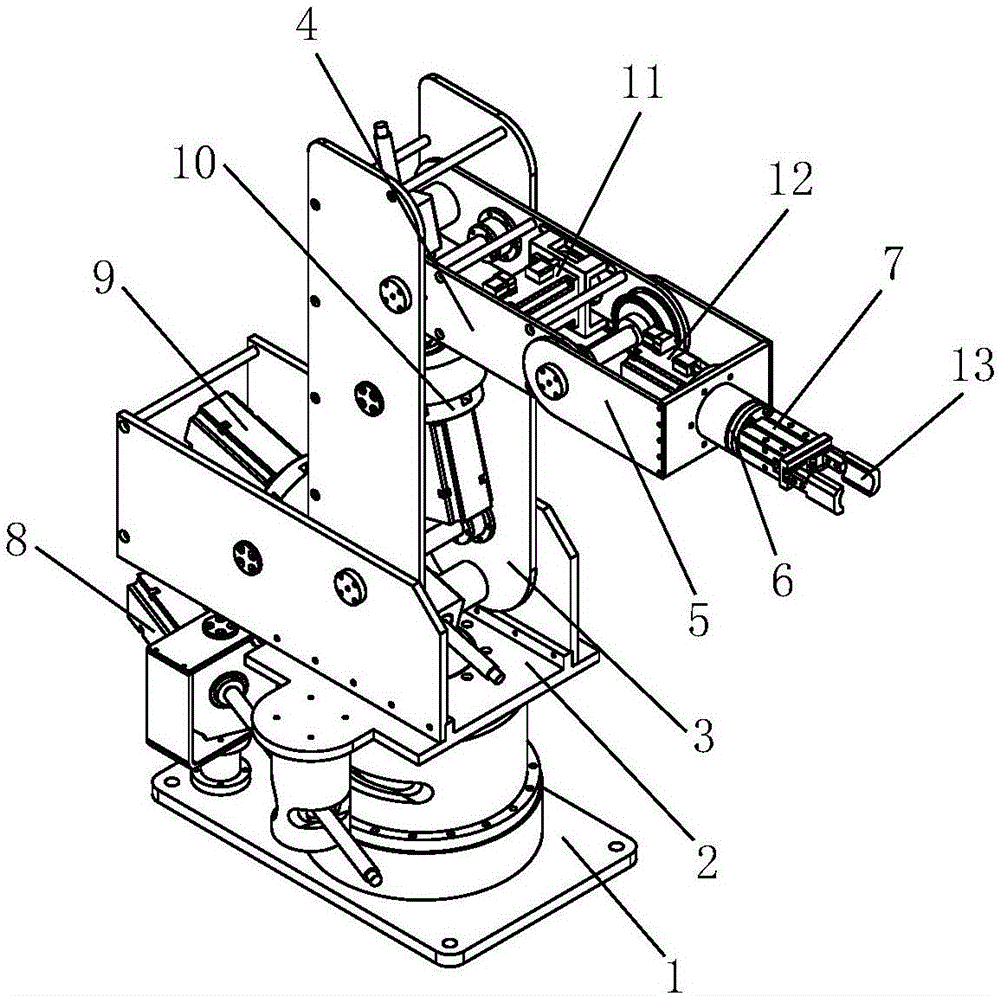

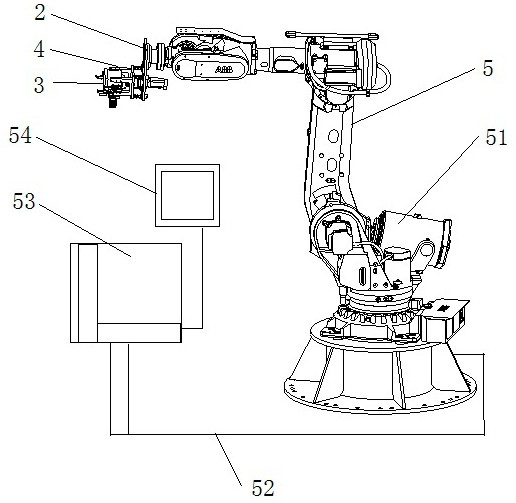

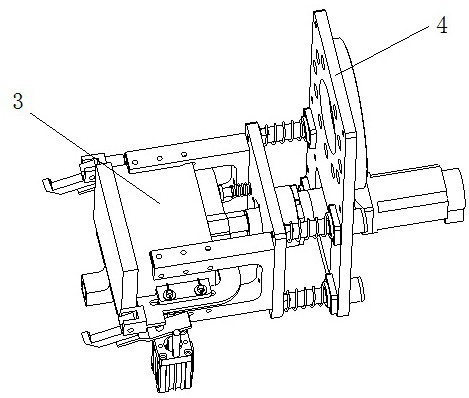

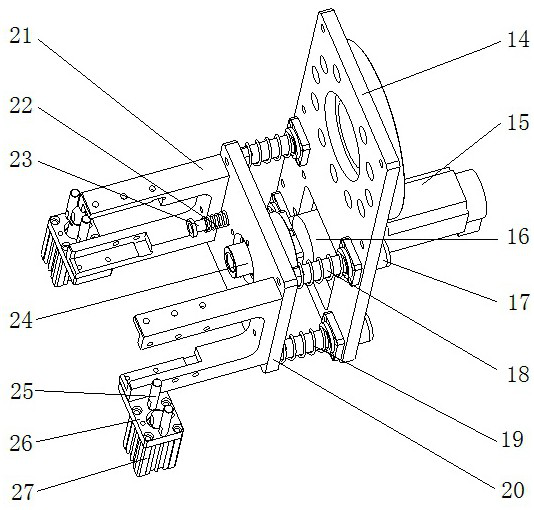

Robot for precise assembling

ActiveCN106426177ALess varietyReasonable structureProgramme-controlled manipulatorGripping headsBall screw driveEngineering

The invention discloses a robot for precise assembling. The robot for precise assembling comprises a base, a rotary table, a large arm, a small arm, a wrist joint, a front end rotational joint and a pneumatic clamping device. The rotary table is rotationally installed on the base. One end of the large arm is hinged to the rotary table, and the other end of the large arm is hinged to one end of the small arm. The other end of the small arm is hinged to one end of the wrist joint, and the front end rotational joint is rotationally installed at the other end of the wrist joint. The pneumatic clamping device is installed at the outer end of the front end rotational joint. A rotary table ball screw driving mechanism used for driving the rotary table to rotate is installed on the base, a large arm ball screw driving mechanism used for driving the large arm to rotate is installed on the rotary table, a small arm ball screw driving mechanism used for driving the small arm to rotate is installed on the large arm, a wrist joint driving mechanism used for driving the wrist joint to rotate is installed on the small arm, and a front end joint driving mechanism used for driving the front end rotational joint to rotate is installed on the wrist joint. The robot for precise assembling is stable in transmission, high in positioning precision and production efficiency, long in service life and wide in application range.

Owner:THE NORTHWEST MACHINE

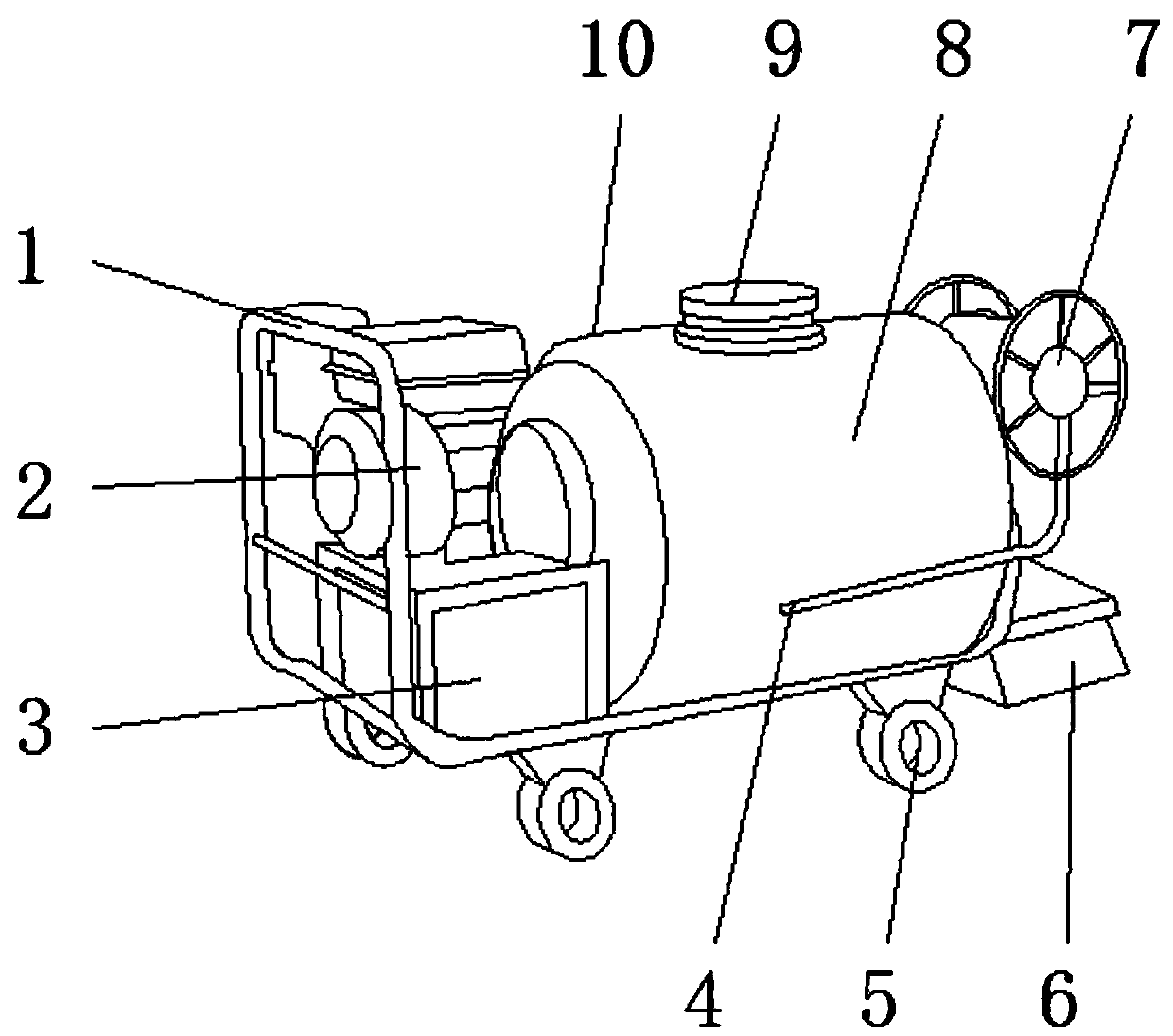

Pesticide spraying device for tea leave planting

InactiveCN107743942AImprove practical performanceLarge working radiusInsect catchers and killersPesticideInternal cavity

The invention discloses a pesticide spraying device for tea leave planting. The device comprises a fixing clamping rack, a material storage tank and a pesticide spraying device body, the material storage tank is fixedly limited onto the pesticide spraying device body, and a supporting rack is welded to the end, close to the material storage tank, of the upper end surface of the pesticide sprayingdevice body; a motor is fixedly limited onto the end surface of the supporting rack, a hand-supporting push rod is welded to the outer end, close to the supporting rack, of the pesticide spaying device body, and mobile wheels are arranged at four corners of the bottom of the pesticide spraying device body in a rolling mode; the fixing clamping rack is arranged on the bottom side of the back end ofthe pesticide spraying device body, sliding grooves which are distributed at equal intervals are formed in an inner cavity of the fixing clamping rack, and fixing racks are inserted in the middles ofthe sliding grooves; rotation shafts are rotatably connected to the portions, located at the upper ends of the fixing racks, of the fixing clamping rack, the rotation shafts and the fixing racks areparallelly arranged, fixed clamping teeth are welded to the inner side ends of the rotation shafts, and a feeding inlet is formed in the upper end of the material storage tank. The pesticide sprayingdevice for tea leave planting can achieve pesticide spraying and seedling protection work.

Owner:WUZHOU YAZHENG AGRI TECH CO LTD

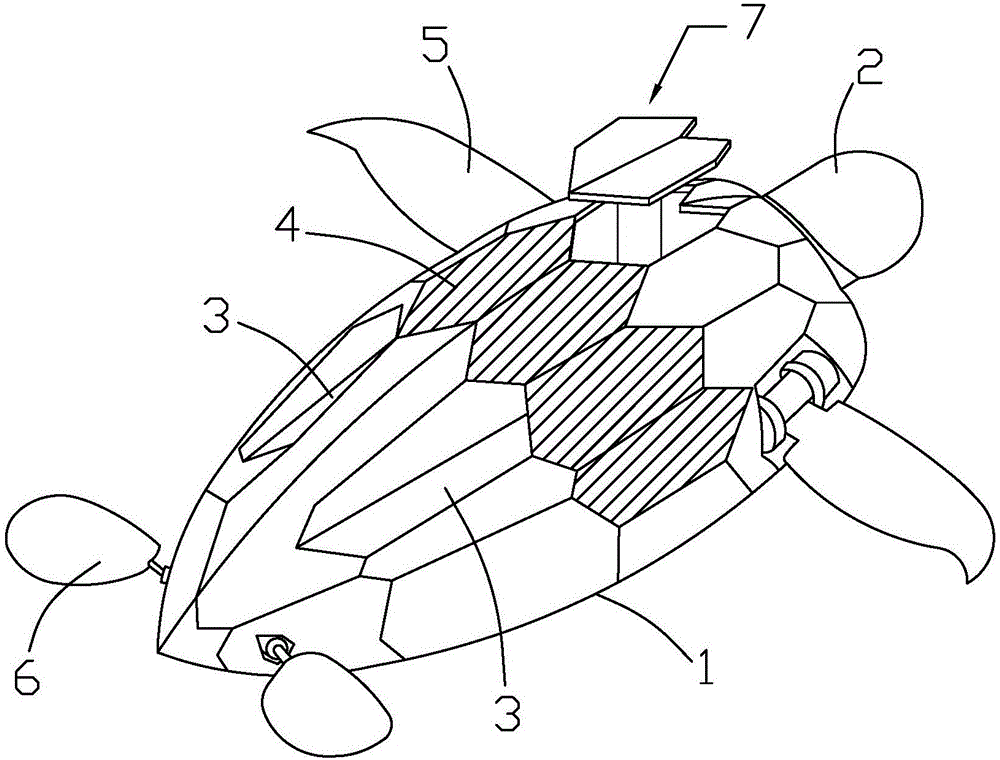

Diversion tunnel underwater monitoring robot and monitoring method thereof

The present invention discloses a diversion tunnel underwater monitoring robot and a monitoring method thereof. The diversion tunnel underwater monitoring robot comprises a diving robot, wherein the diving robot comprises a housing and a bionic sea turtle head, an infrared camera is arranged inside the bionic sea turtle head, both sides of the housing are respectively provided with a lifting water wing and a turning tail wing, the top surface of the housing is provided with a solar panel, one side of the solar panel is provided with a power propulsion groove, and a mechanical power mechanism, a main electric energy storage box and a standby electrical box is arranged inside the housing. According to the monitoring method, a base station transmits a signal, the signal is amplified through a movable signal conversion device, the amplified signal is transmitted to the diving robot, and the diving robot is controlled to perform underwater monitoring on the diversion tunnel. With the diversion tunnel underwater monitoring robot and the monitoring method of the present invention, the two problems of insufficient diving robot power supply and weak signal conversion receiving intensity are effectively solved, the weight of the diving robot is effectively reduced, the labor intensity is reduced, and the monitoring work radius and the control performance of the diving robot are improved.

Owner:HANGZHOU HUANENG SAFETY ENG POLYTRON TECH CO LTD

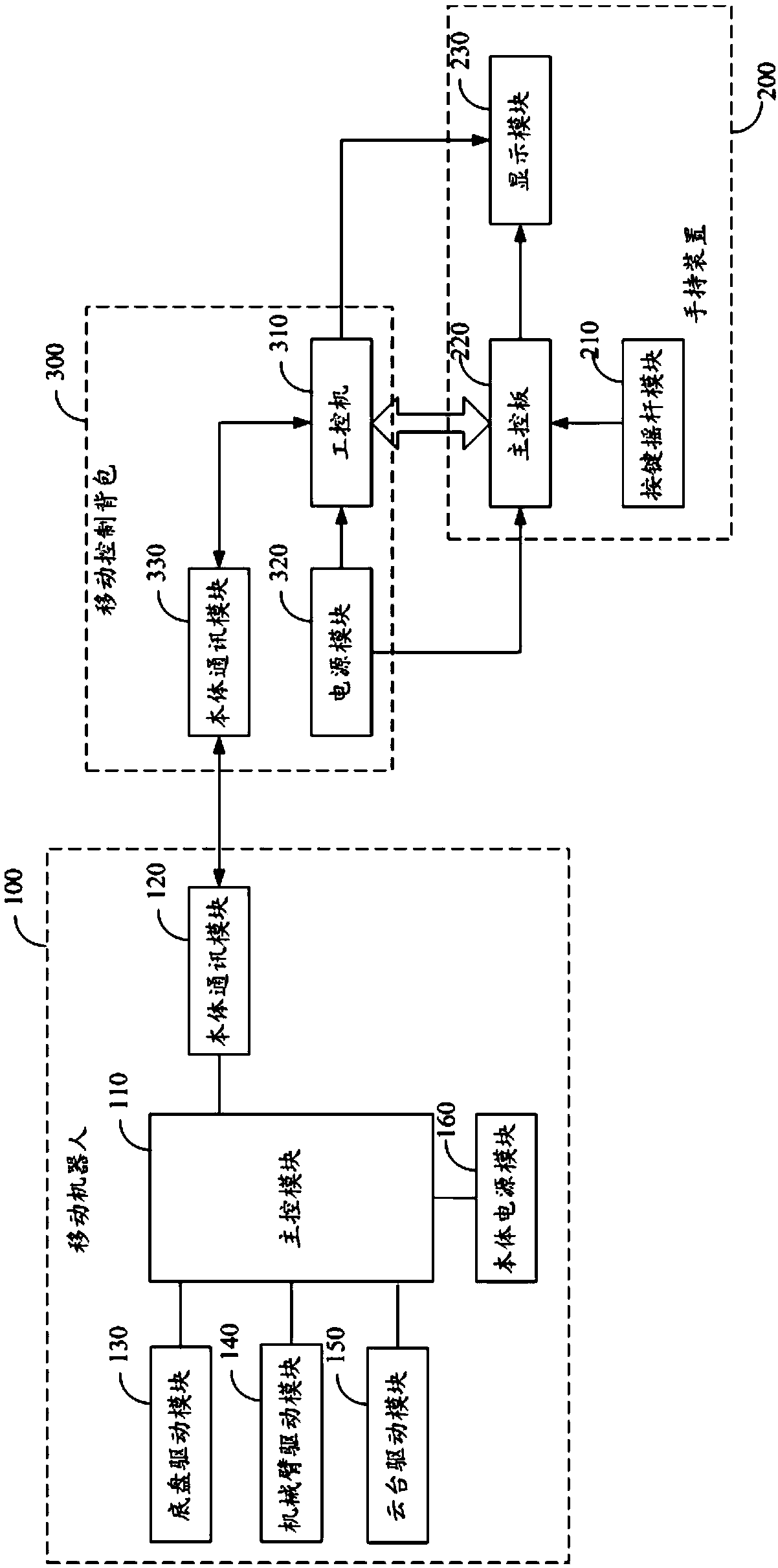

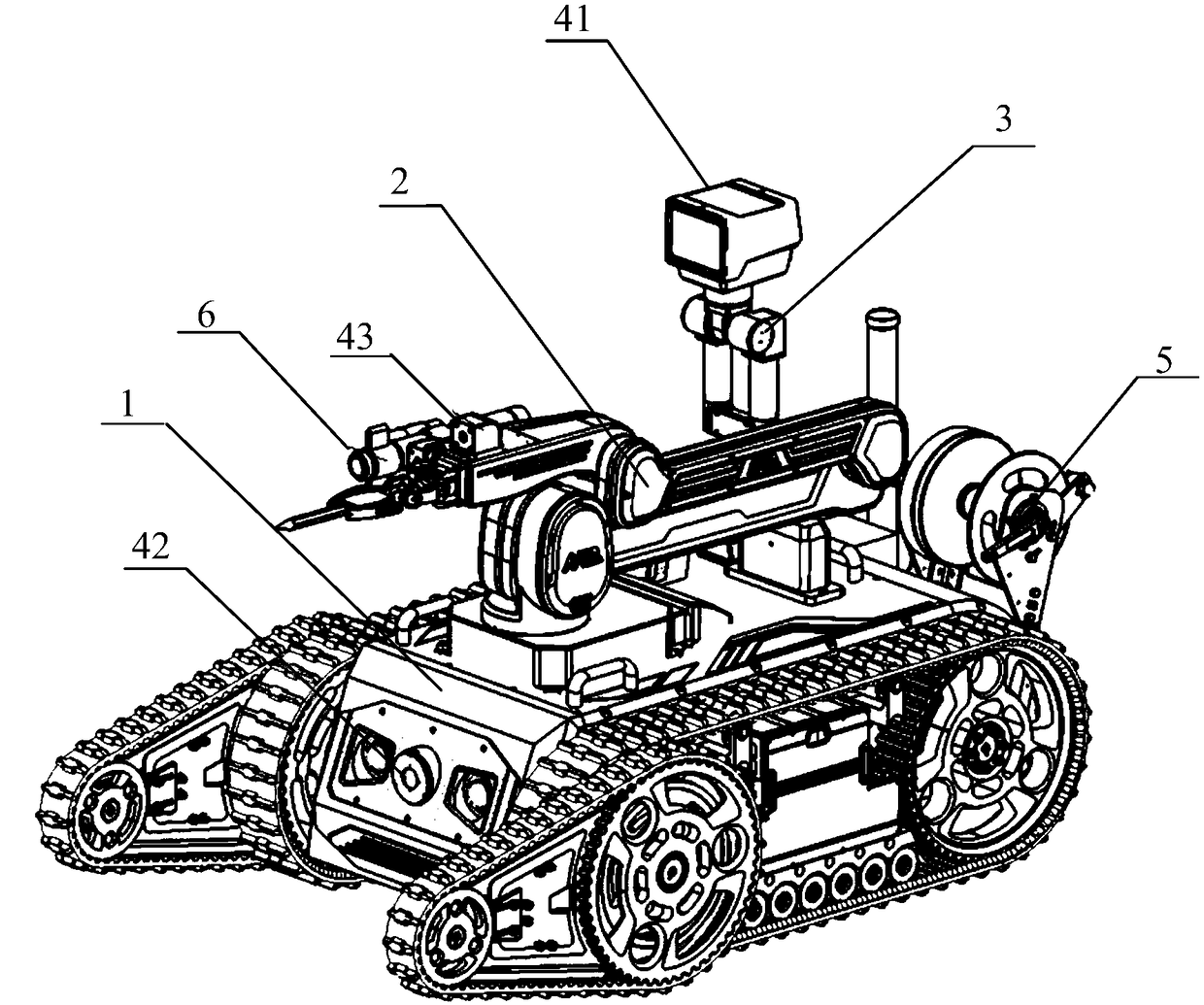

Public security mobile robot system and public security mobile robot

The invention relates to a public security mobile robot system. The public security mobile robot system comprises a mobile robot and a remote control terminal. The remote control terminal comprises ahandheld device and a mobility control knapsack. The handheld device comprises a key rocking bar module, a master control panel and a display module. The mobility control knapsack comprises an industrial personal computer, a power module and a knapsack communication module, wherein the industrial personal computer, the power module and the knapsack communication module are encapsulated in a sack body. The knapsack communication module is used for being in wireless communication with the mobile robot. The mobile robot comprises a robot body, a master control module, a body communication module,a chassis drive module, a mechanical arm drive module, a cloud deck drive module and a plurality of cameras, wherein the master control module, the body communication module, the chassis drive module, the mechanical arm drive module, the cloud deck drive module and the multiple cameras are arranged on the robot body. The mobile robot and the mobility control knapsack can further be switched in awired / wireless communication mode. According to the public security mobile robot system, the remote control terminal is composed of the handheld device and the mobility control knapsack, so that carrying and using are made convenient, operators can control the public security mobile robot system while walking, the working radius of the robot is increased, and the mobile inspection problem is solved.

Owner:北京军立方机器人科技有限公司

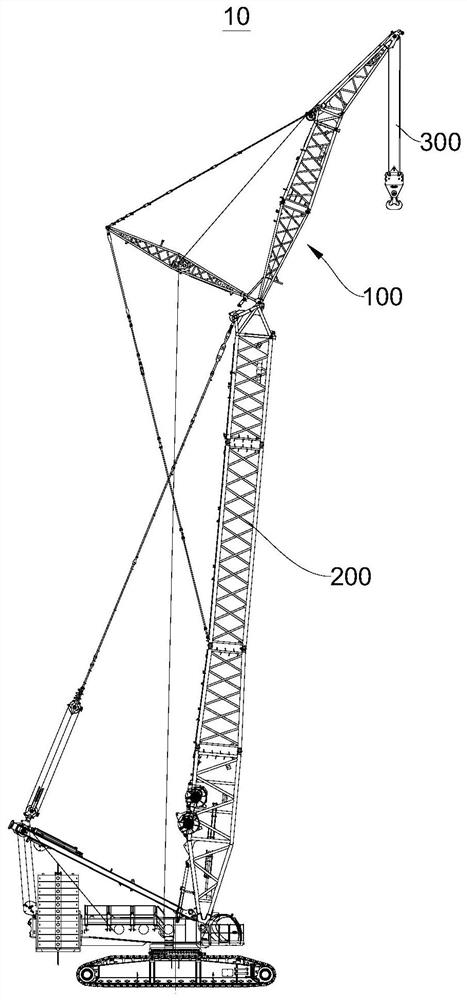

Method for mounting blast furnace framework structure by utilizing transverse hoisting beam

InactiveCN104709813ALarge working radiusExpand the lifting rangeLoad-engaging elementsTower craneIndustrial engineering

The invention relates to a method for mounting a blast furnace framework structure by utilizing a transverse hoisting beam, and is characterized in that firstly, the H-shaped transverse hoisting beam is prepared, and hoisting lugs are respectively welded on an upper flange plate and a lower flange plate of the transverse hoisting beam; before hoisting, a component ready for hoisting is welded with a hoisting lug and is connected at the lower side of the transverse hoisting beam through a steel wire rope; followed by, one end, being connected with the component, of the transverse hoisting beam is connected with a hook head of a 4000 t.m tower crane by a steel wire rope, the other end, being not connected with the component, of the transverse hoisting beam is connected with a hook head of the 4000 t.m tower crane by a steel wire rope and a guide chain, and the guide chain is pulled tightly; finally, the component is slowly hoisted; when the component is hoisted 100 mm away from the ground, hoisting is stopped, and the tensile force of the guide chain is adjusted, so that the transverse hoisting beam is kept horizontal, and after adjusting is finished, hoisting is continued and the component is mounted at a right position. The operation is simple; and through the transverse hoisting beam, the working radius of the tower crane is extended, the hoisting scope of the tower crane is enlarged, the construction cost is reduced, and the requirement of green construction is met.

Owner:CHINA MCC 2 GRP CO LTD

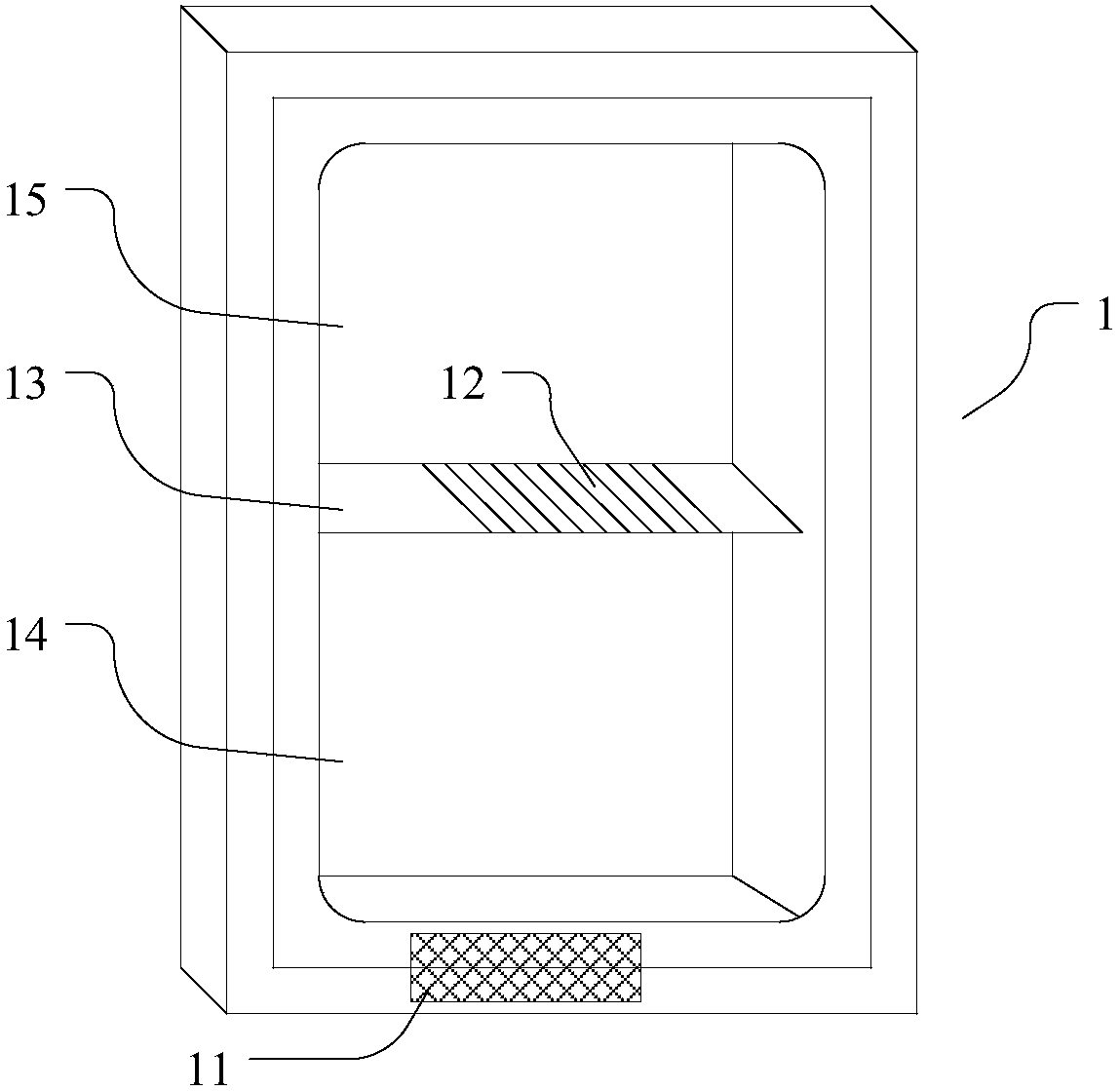

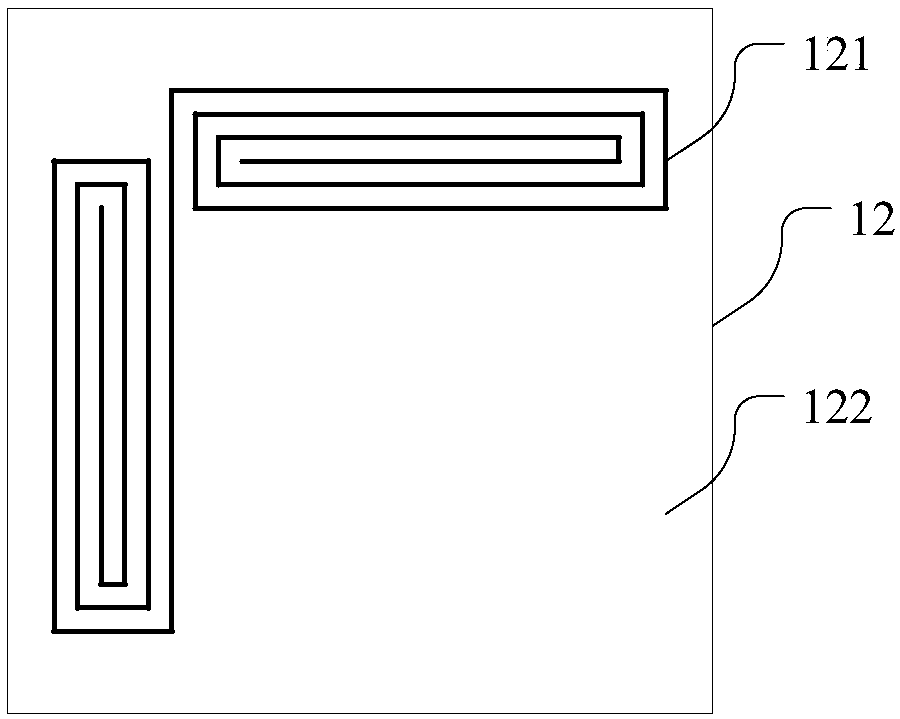

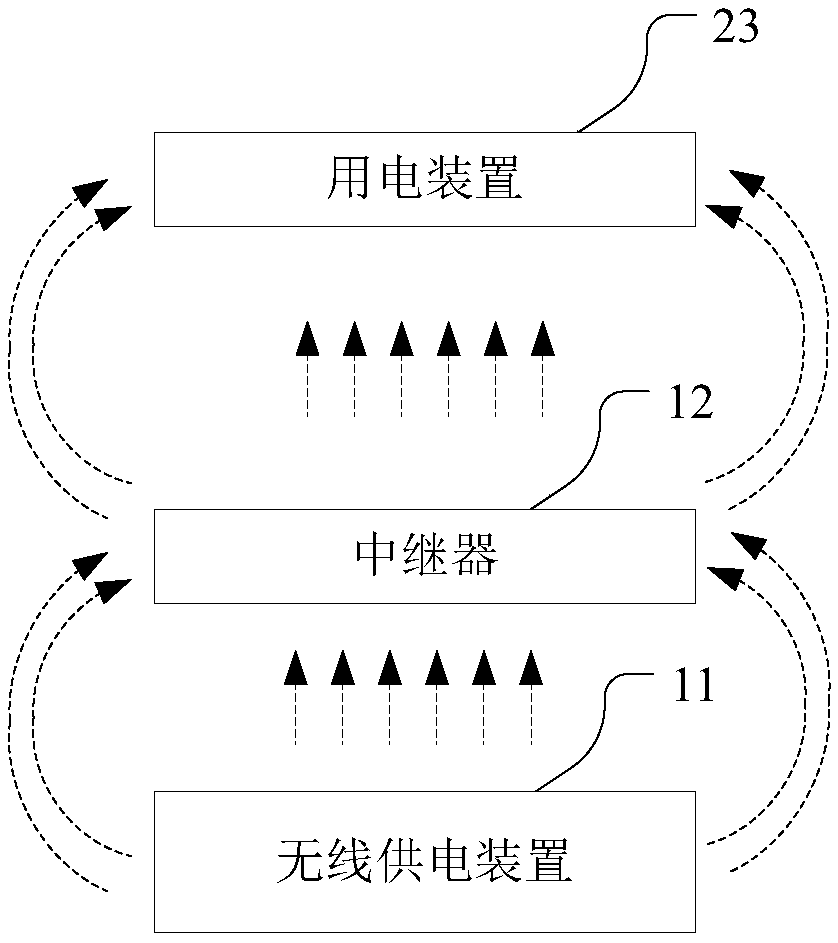

Household electrical appliance

ActiveCN108206708ALarge working radiusExpand coverageNear-field transmissionCircuit arrangementsElectromagnetic shieldingElectromagnetic signal receiver

A household electrical appliance comprises a wireless power supply device, at least one repeater and a power utilization device. The wireless power supply device emits an electromagnetic signal when power-on; the repeater is arranged in the coverage range of the electromagnetic signal emitted by the wireless power supply device, and transmits the electromagnetic signal when receiving the signal; and an electromagnetic signal receiver is arranged in the power utilization device, and generates current to supply power to the power utilization device when the electromagnetic signal is detected. Thus, the working radius of the wireless power supply device can be increased.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

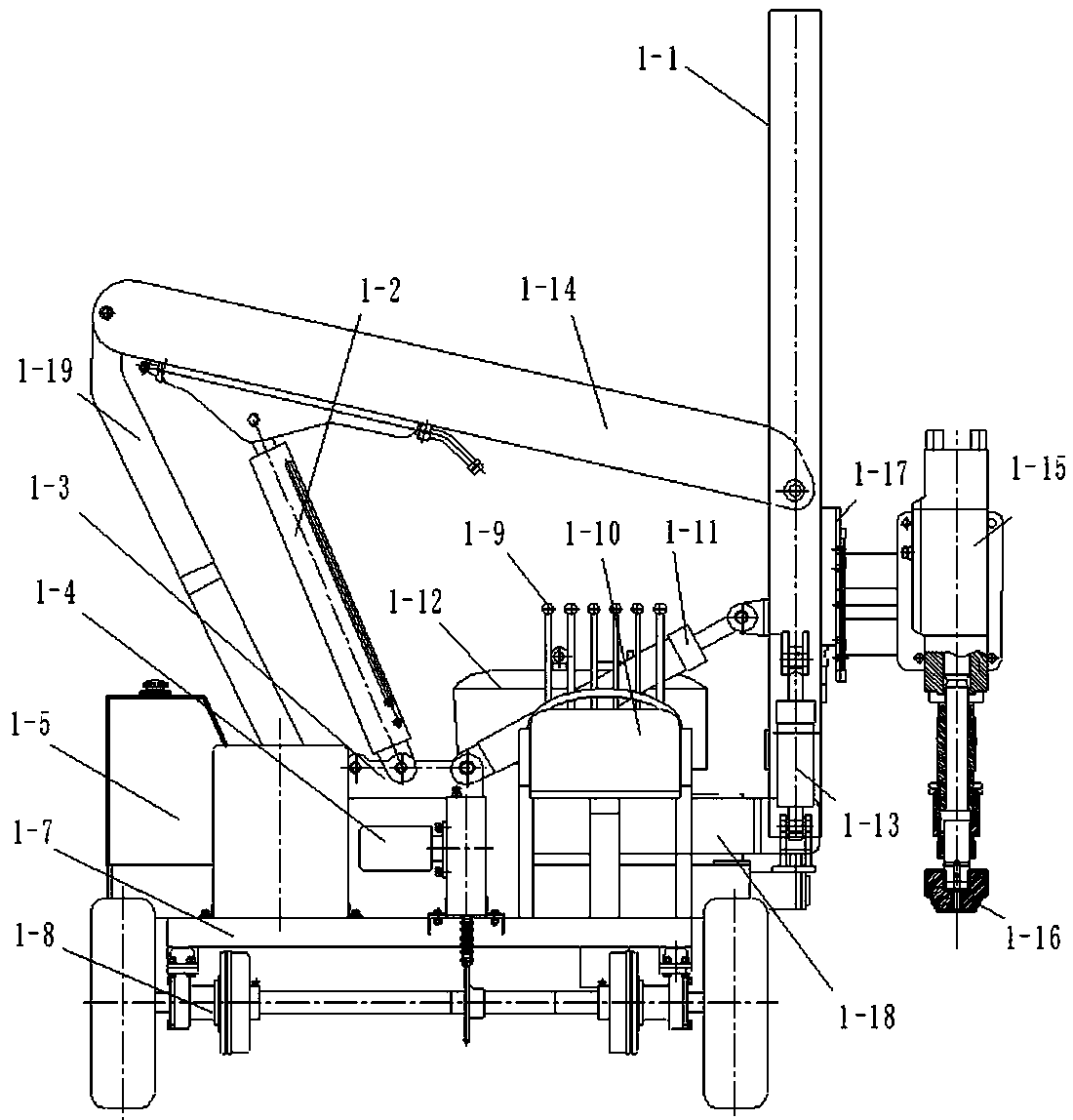

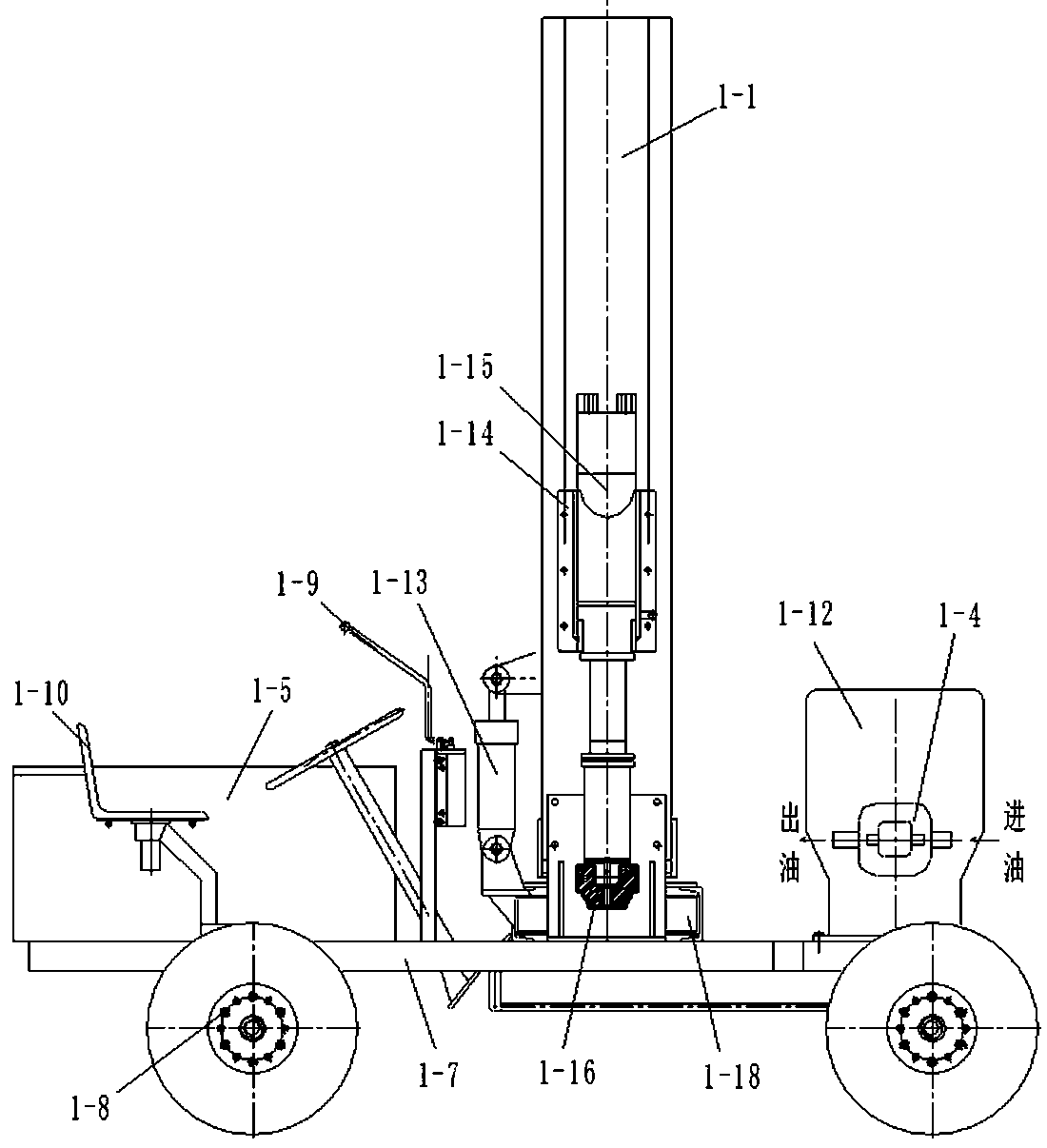

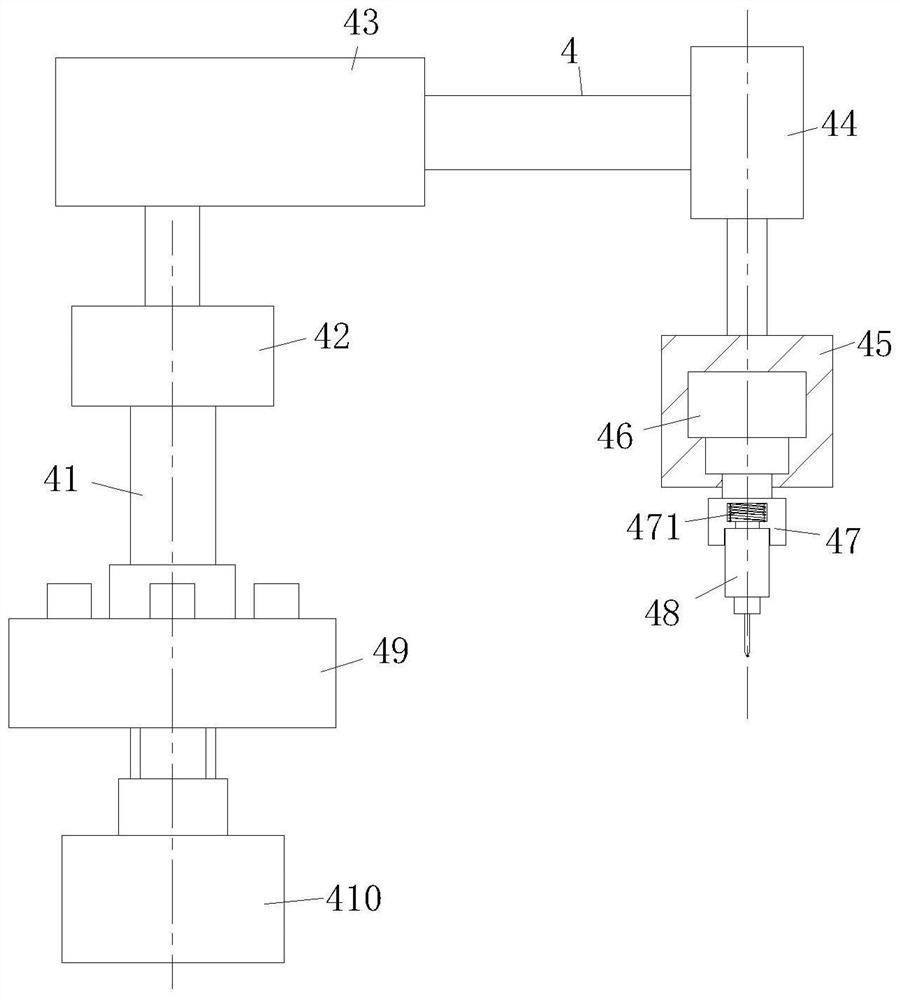

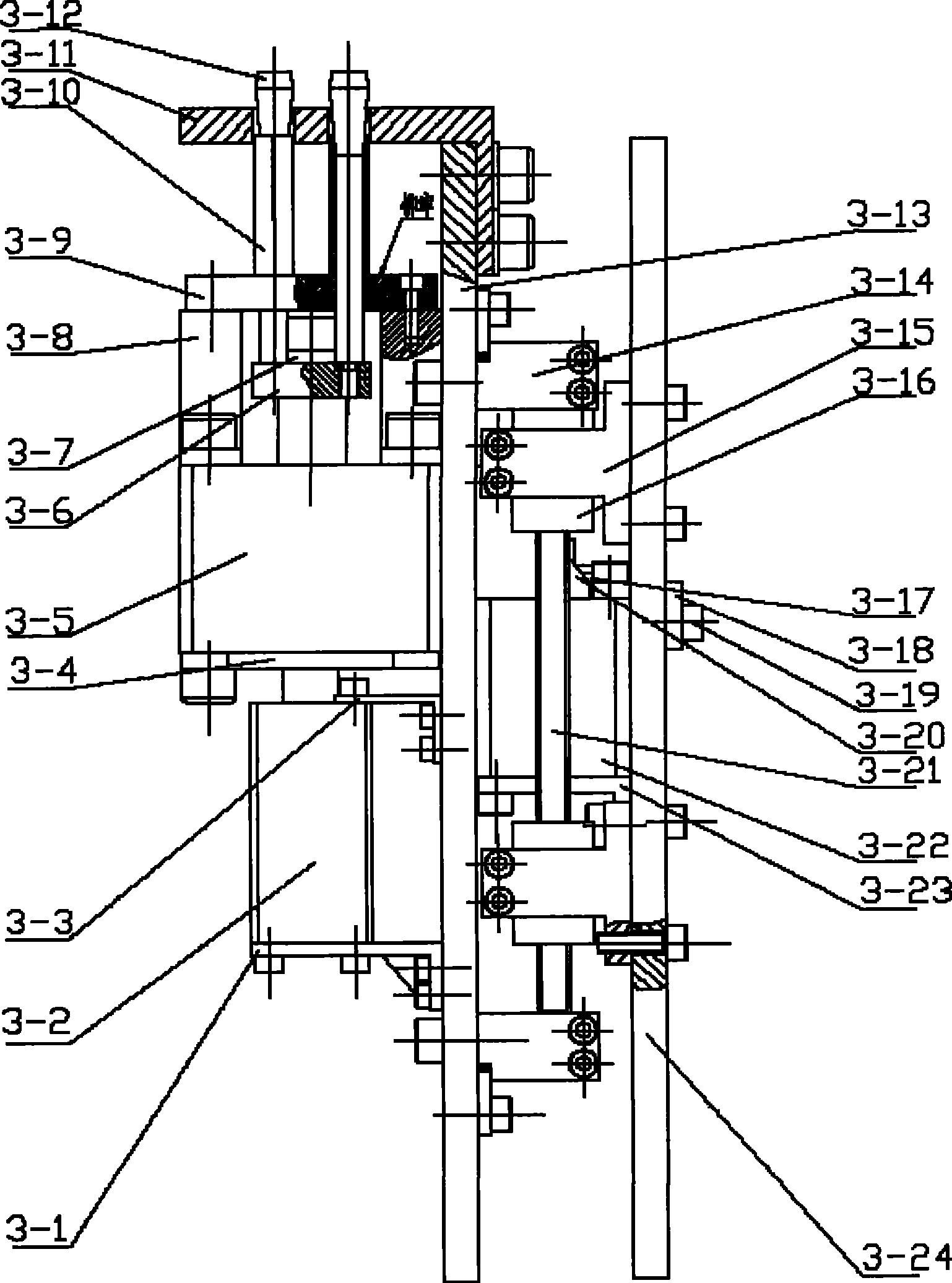

Operating mechanism of vehicle-mounted highway guardrail pile driving and pulling machine

ActiveCN108532603AImprove work efficiencyImprove verticalityBulkheads/pilesRoadway safety arrangementsEngineeringOperating speed

The invention provides an operating mechanism of a vehicle-mounted highway guardrail pile driving and pulling machine and belongs to vehicle-mounted highway guardrail pile driving and pulling machines. The operating mechanism is connected with a hydraulic oil tank on a transverse slideway. The lower portions of stand columns are connected with a limit stop and a pile gripper in sequence. An operating device is connected to the stand columns through a lifting device. The lifting device slides up and down along the stand column to drive the operating device to move up and down. The stand columnsare hinged to one end of a transverse device through a pitching device and can do transverse motion along with the transverse device and do pitching motion with the transverse device as the fulcrum point. The bottom of the transverse device is hinged to a rotation device. A left-right device is hinged between the transverse device and the rotation device. The transverse device is driven by the left-right device to do left-right motion with the stand columns with left and right hinged shaft holes at the bottom as fulcrum points. The operating mechanism has the advantages that operation is easy; the perpendicularity of driven guardrail piles is high; vibration of the whole machine is small; the service life of the whole machine is prolonged; the operation comfort of working staff is improved; the operating speed is high and the working radius is large.

Owner:徐州万盛工程设备有限公司

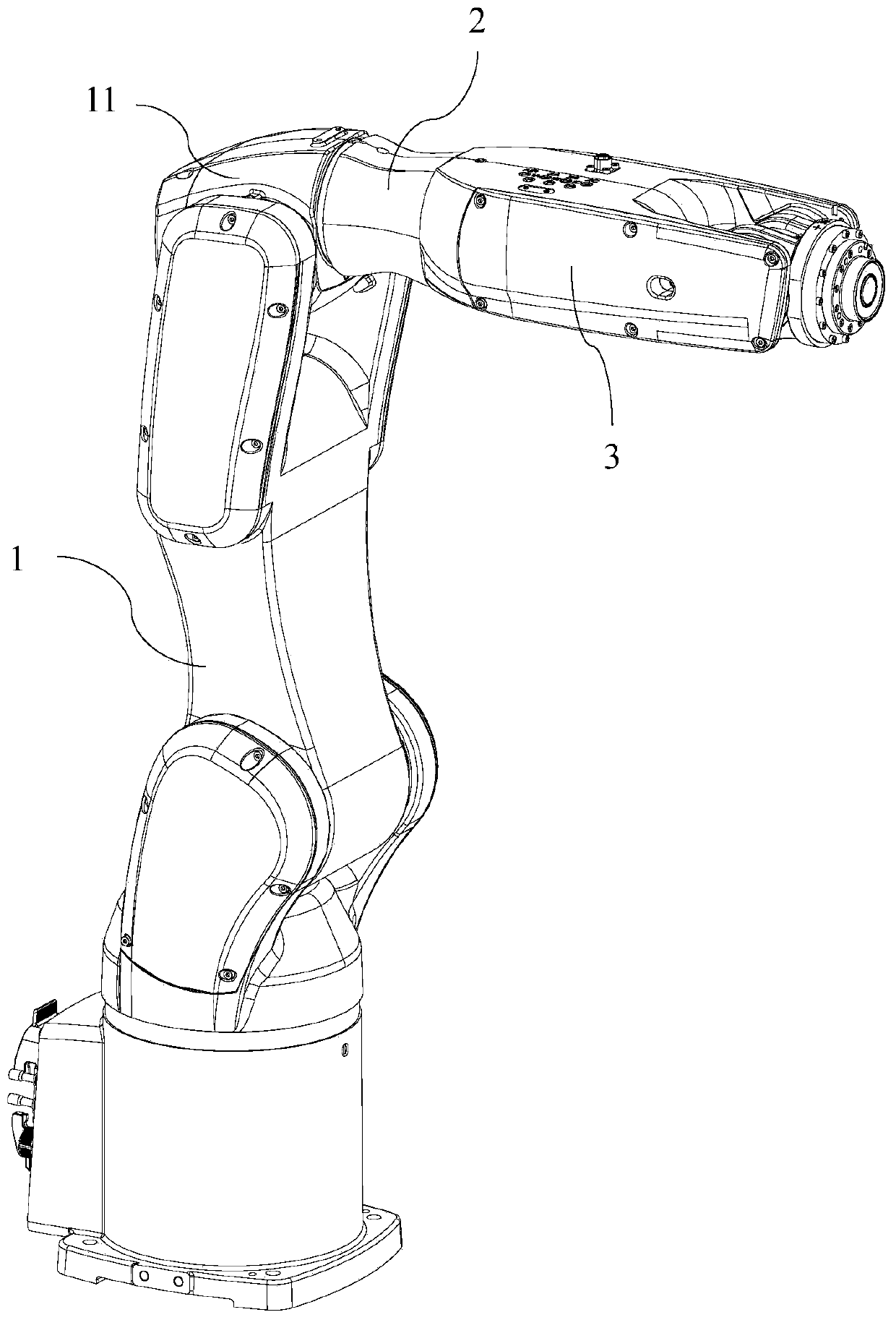

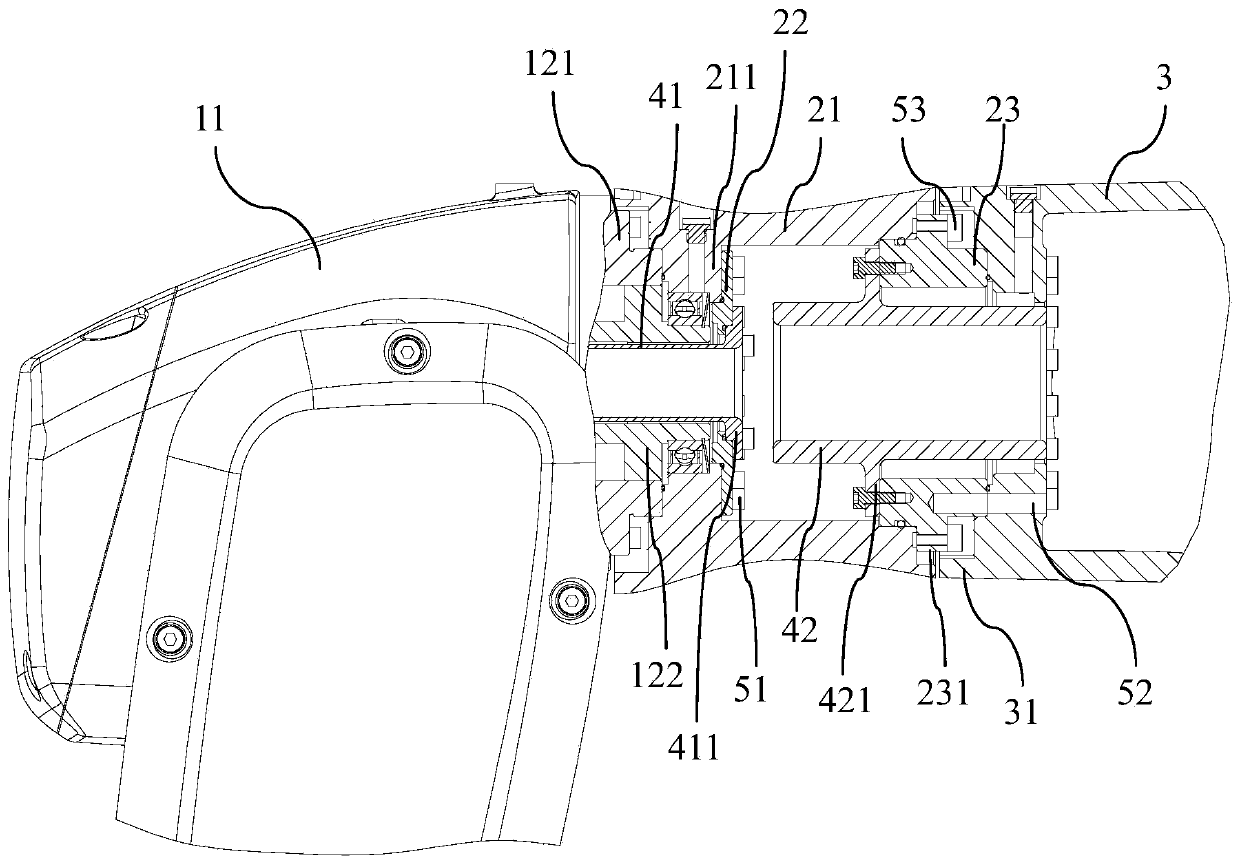

Industrial robot

PendingCN111546314ALarge working radiusIncrease flexibilityProgramme-controlled manipulatorIndustrial roboticsMechanical engineering

The invention provides an industrial robot which comprises a base body assembly, an extension arm assembly and a front arm assembly. The base body assembly comprises an elbow shell and a hollow type speed reducer fixedly arranged on a seam allowance at the front end of the elbow shell; the first end of the axial direction of the extension arm assembly is fixedly arranged at the output end of the speed reducer through a first screw; the front arm assembly is fixedly arranged at the second end of the axial direction of the extension arm assembly through a second screw; the installation surface of the first end of the axial direction of the extension arm assembly and the installation surface of the front arm assembly are the same; and the installation surface of the second end of the axial direction of the extension arm assembly and the installation surface of the output end of the speed reducer are the same. According to the industrial robot provided by the embodiment of the invention, the end faces of two ends of the axial direction of the extension arm assembly are the same as the installation surface of the front arm assembly and the installation surface of the output end of the speed reducer, so that the arm length of the industrial robot can be increased, the working radius of the industrial robot can be effectively increased, and meanwhile, the flexibility in assembling theindustrial robot is improved.

Owner:SUZHOU INOVANCE TECH CO LTD

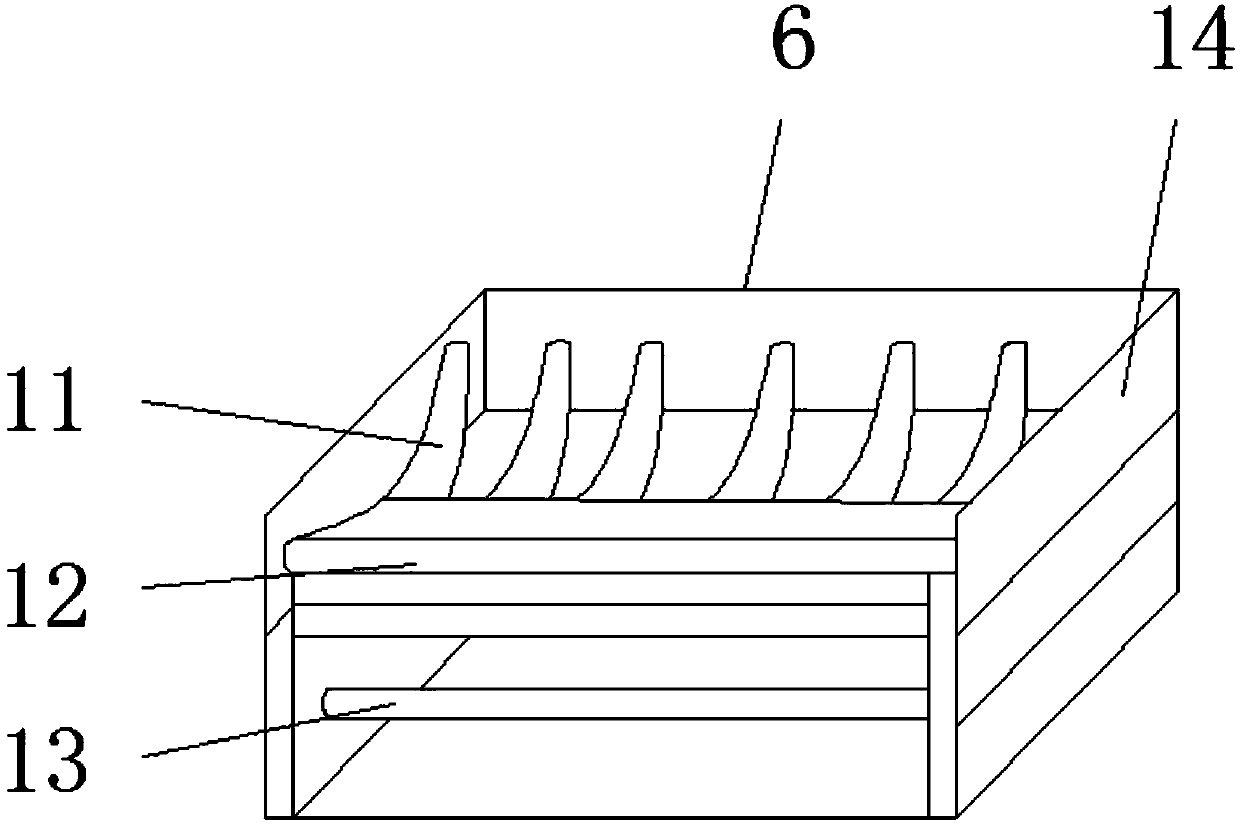

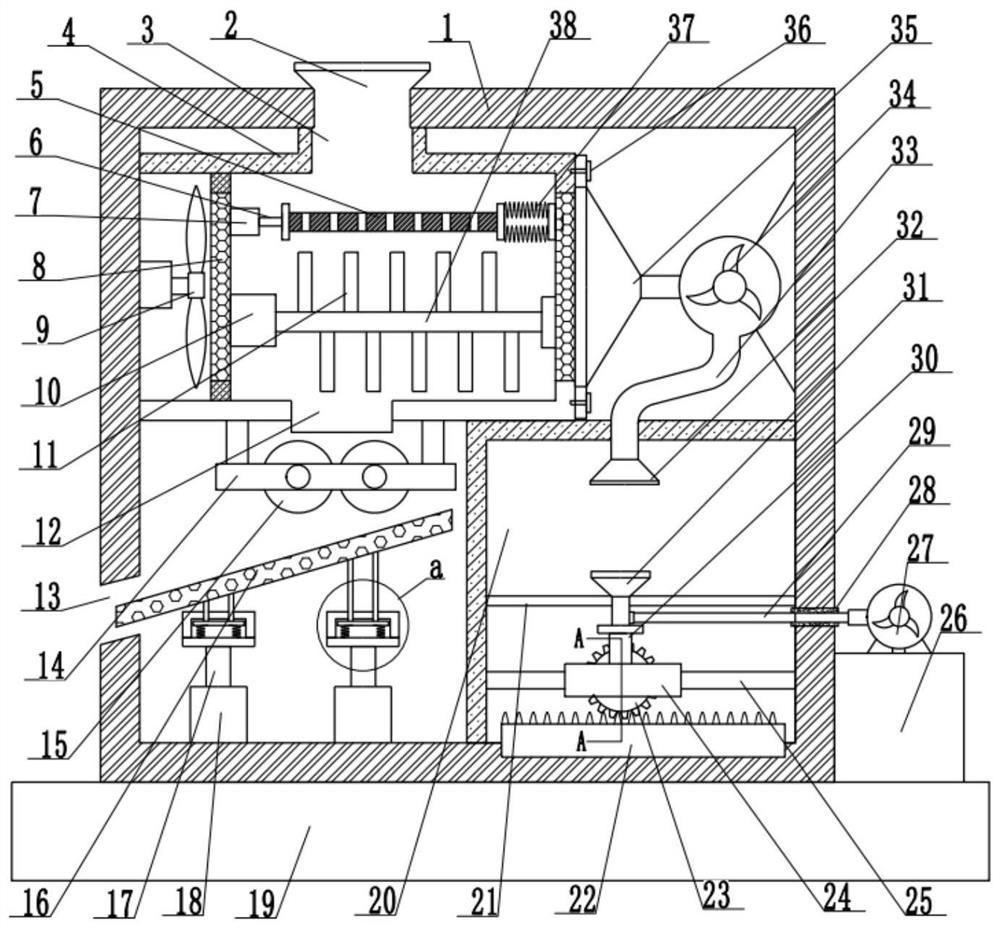

Dust removal device based on rice mill

InactiveCN112473770AAvoid cloggingAvoid pollutionGrain huskingGrain polishingAgricultural engineeringDust control

The invention discloses a dust removal device based on a rice mill, and belongs to the technical field of rice mills. The dust removal device based on the rice mill solves the problem of poor dust removal effect of an existing dust removal device based on a rice mill. The device comprises a rice mill shell, a stirring shell, a first servo motor, a fan, a driving gear, a dust collection valve, anda high-pressure water spray valve; the stirring shell is connected with a feeding port in the top of the rice mill shell through a stirring shell feeding port; the first servo motor is connected witha stirring shaft through a coupler; the surface of the stirring shaft is connected with a stirring paddle; the fan is fixed to one side of a ventilation net, and the other side of the ventilation netis connected with the dust collection valve through a bolt; a dust valve is connected with the dust collection valve through a air extracting pump and a dust removal pipe; the dust valve is fixedly connected with the inner wall of a dust removal chamber; the high-pressure water spray valve is connected with a water pump through a telescopic hose and further connected with a sliding table through ahigh-pressure water spray valve mounting plate; the driving gear is connected with a second servo motor through a driving shaft; and the driving gear is further engaged with a rack. The dust removaldevice based on the rice mill has the characteristics of being good in dust removal effect.

Owner:HUNAN JINSONG MACHINERY

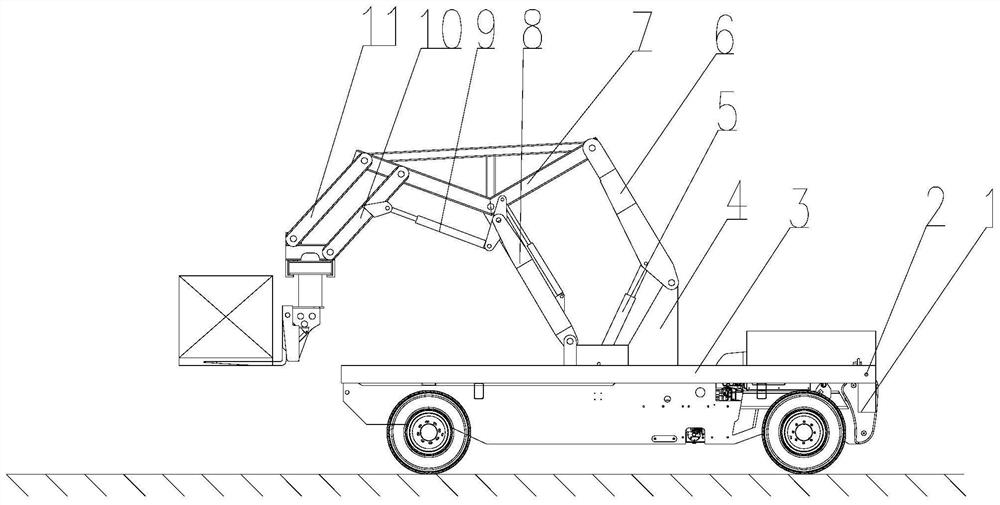

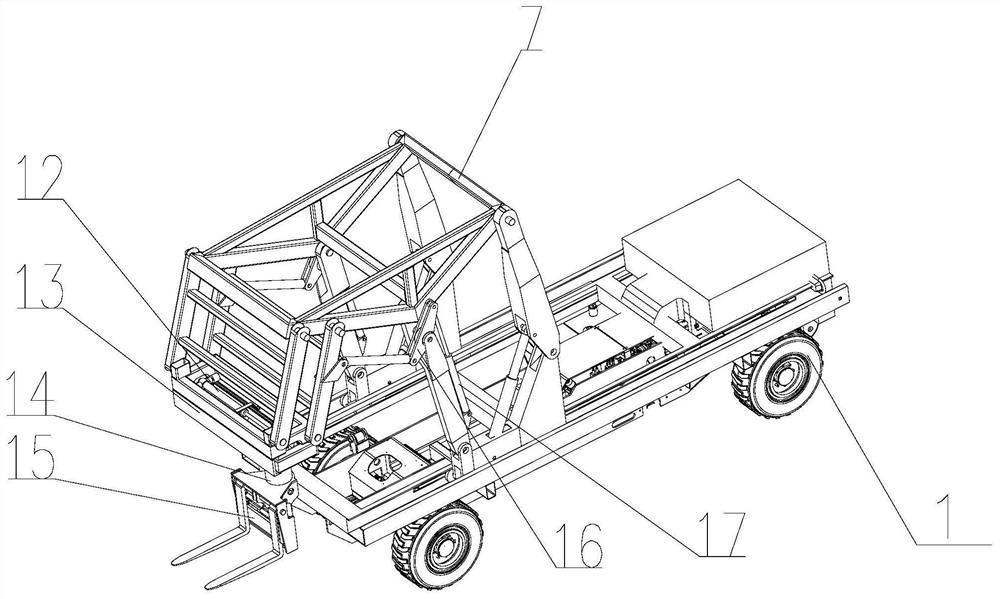

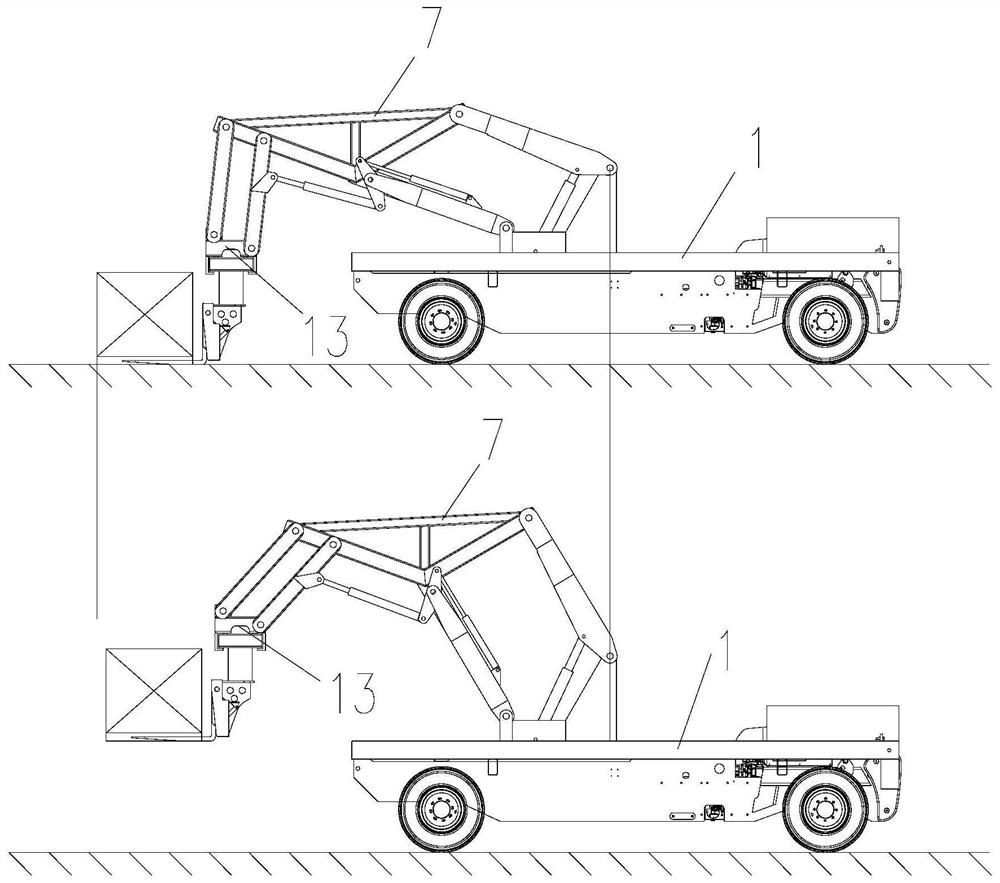

Cargo loading and unloading device and cargo loader

ActiveCN112079294AImprove loading and unloading efficiencySolving Telescopic Boom Clearance ProblemsLifting devicesLoading/unloading vehicle arrangmentTelescopic cylinderMechanical engineering

The invention discloses a cargo loading and unloading device and a cargo loader. The cargo loading and unloading device comprises a support connected with a vehicle body, a transfer frame and a translation frame which are arranged in a spaced manner in the front-back direction of the vehicle body, and a cargo loading and unloading mechanism arranged on the translation frame and used for being connected with cargoes. A first connecting rod and a second connecting rod which are arranged in parallel are hinged between the transfer frame and the support to form a first parallelogram connecting rodstructure; and a first telescopic cylinder used for pushing the first connecting rod and the second connecting rod to swing front and back is connected between the support and the first connecting rod. A third connecting rod and a fourth connecting rod which are arranged in parallel are hinged between the translation frame and the transfer frame to form a second parallelogram connecting rod structure; and a second telescopic cylinder for pushing the third connecting rod and the fourth connecting rod to lift and swing back and forth is hinged between the second connecting rod and the third connecting rod. Accordingly, through the movement of the transfer frame and the translation frame in the front-back direction and the up-down direction of the vehicle body, efficient loading, unloading or transferring of batched goods can be achieved.

Owner:SUNWARD INTELLIGENT EQUIP +1

Multi-station numerical control lathe

PendingCN114147241ASave time and costImprove processing efficiencyAutomatic control devicesAuxillary equipmentNumerical controlElectric machinery

The invention relates to the field of numerical control lathes, in particular to a multi-station numerical control lathe which comprises a flow guide mechanism, a charging mechanism, a limiting mechanism, a cutting mechanism and a flushing mechanism. The sliding block sleeves the sliding guide rod to form four stations, one station is used for lathe machining, one station is used for flushing, one station is used for discharging, one station is used for feeding, and the four stations are synchronously carried out to form streamline work, so that the time cost is saved, and the machining efficiency is improved; through the cooperation effect of a groove rod and a sliding bolt, the movement trend of a push rod and the movement trend of a limiting sliding bolt are consistent, and therefore the state of a material carrying plate is controlled, the position of a first chuck is controlled, and discharging and feeding are facilitated; the fixed disc needs to be fixedly installed, a second connecting rod is driven to rotate through a sixth motor, then a movable disc is driven to change different directions and angles through a first connecting rod, and therefore the high-pressure punch is driven to wash workpieces from different angles, sufficient cleaning is guaranteed, and the surfaces of the workpieces are prevented from being scratched by metal scraps.

Owner:田玉

Nuclear power steam generator pipe detection robot

InactiveCN101364452BEasy accessLower requirementNuclear energy generationNuclear monitoringDrive shaftNuclear power

The invention provides a pipeline inspection robot for a nuclear steam generator, which comprises two pawing mechanisms hinged with an upper cantilever via a driving shaft and a lower cantilever via a driven shaft. The upper cantilever is composed of two segments which are hinged with each other via a driving shaft; the lower cantilever is composed of two segments which are hinged with each othervia a driven shaft; a motor is connected with the lower ends of both the driving shaft between the upper cantilever and the two pawing mechanisms and the driving shaft between the two segments of theupper cantilever; and a potentiometer is arranged at the upper end of each driving shaft and is connected with a sensor guide arm which is hinged with a fixed column fixed on the upper cantilever. The pipeline inspection robot has the following advantages: small volume, so as to be easy to be put into the steam generator by an operator through a narrow manhole; convenient energy availability, andflexible and reliable control; cantilever structure with a relatively large working radius after being unfolded; low requirements for the motor, and reliable operation; and good adaptability of replacement parts to different apertures and aperture plates.

Owner:HARBIN ENG UNIV

Bird repelling unmanned aerial vehicle

InactiveCN107745815ASimple structureEasy to operateAircraft componentsAnimal repellantsUncrewed vehicleLoudspeaker

The invention belongs to the technical field of unmanned aerial vehicles and particularly relates to a bird repelling unmanned aerial vehicle. The bird repelling unmanned aerial vehicle comprises an unmanned aerial vehicle body, a loudspeaker, a nozzle, a compressed bird repelling agent and unmanned aerial vehicle supports. The loudspeaker is arranged above the unmanned aerial vehicle body; the nozzle is arranged in one unmanned aerial vehicle support, the outer end of the nozzle is exposed, and the nozzle is connected with the compressed bird repelling agent; the compressed bird repelling agent is arranged in the unmanned aerial vehicle body; and the four unmanned aerial vehicle supports are arranged below the unmanned aerial vehicle body and used as undercarriages, and the nozzle is installed on any one of the four unmanned aerial vehicle supports. The working mode of the unmanned aerial vehicle includes the steps that a worker operates the unmanned aerial vehicle to get close to a region where a bird flock is located and controls the loudspeaker to play bird flock repelling sound, and meanwhile, the compressed bird repelling agent is sprayed through the nozzle until the bird flock leaves. After the compressed bird repelling agent is used up, the unmanned aerial vehicle can fly back to the ground to replace or fill the compressed bird repelling agent. The bird repelling unmanned aerial vehicle is simple in structure, convenient to operate, capable of repelling the bird flock at upper air, large in working radius and remarkable in working effect due to the utilization of combination of the sound and the bird repelling agent.

Owner:FOSHAN SHENFENG AVIATION SCI & TECH

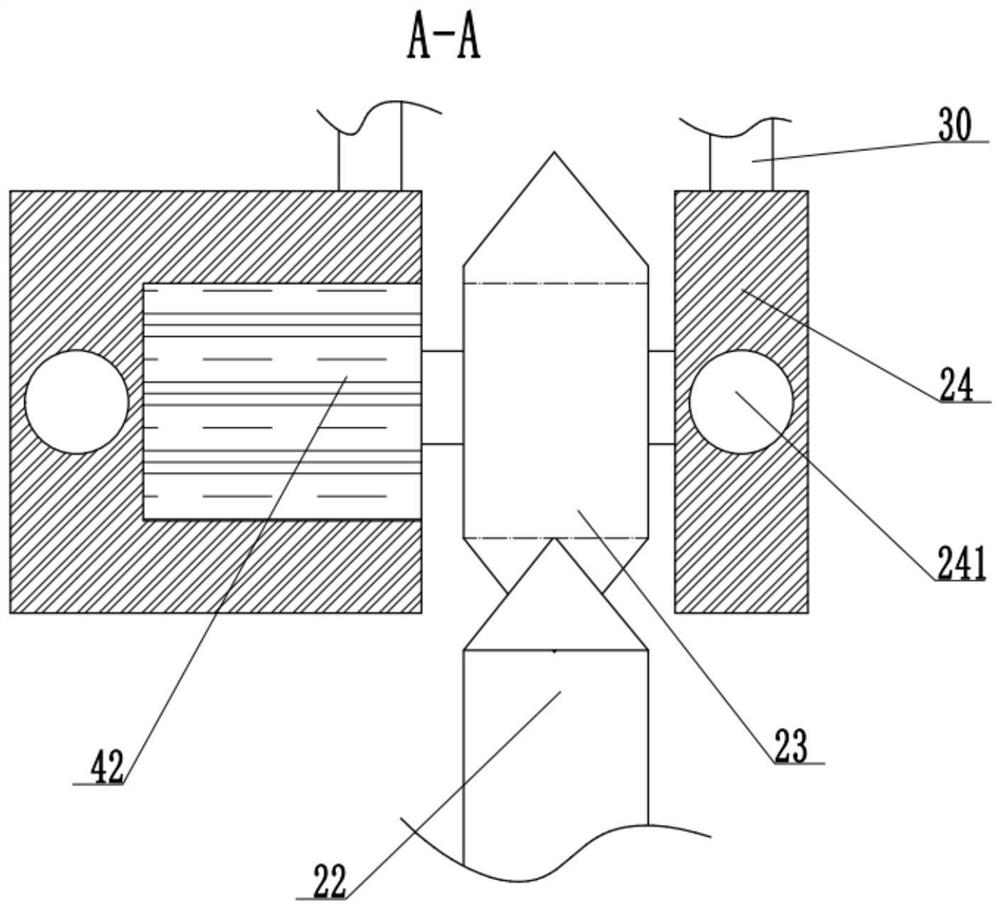

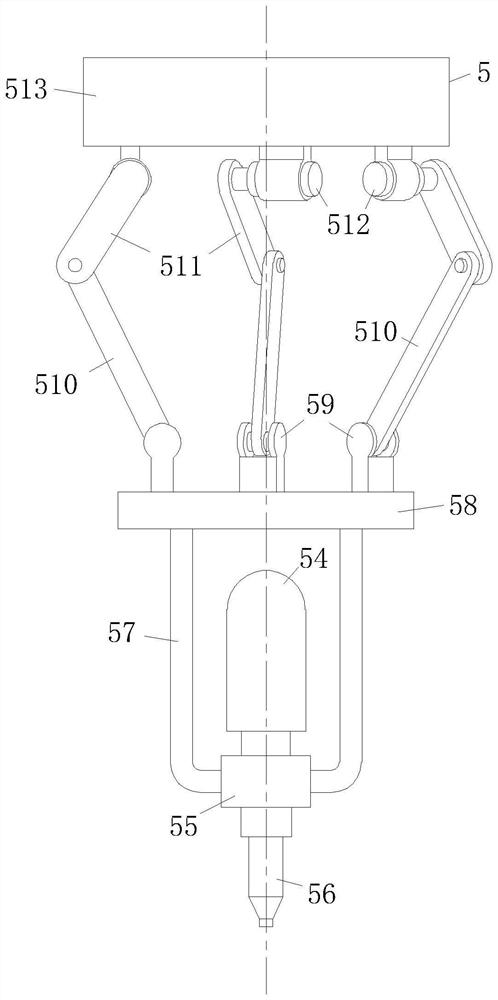

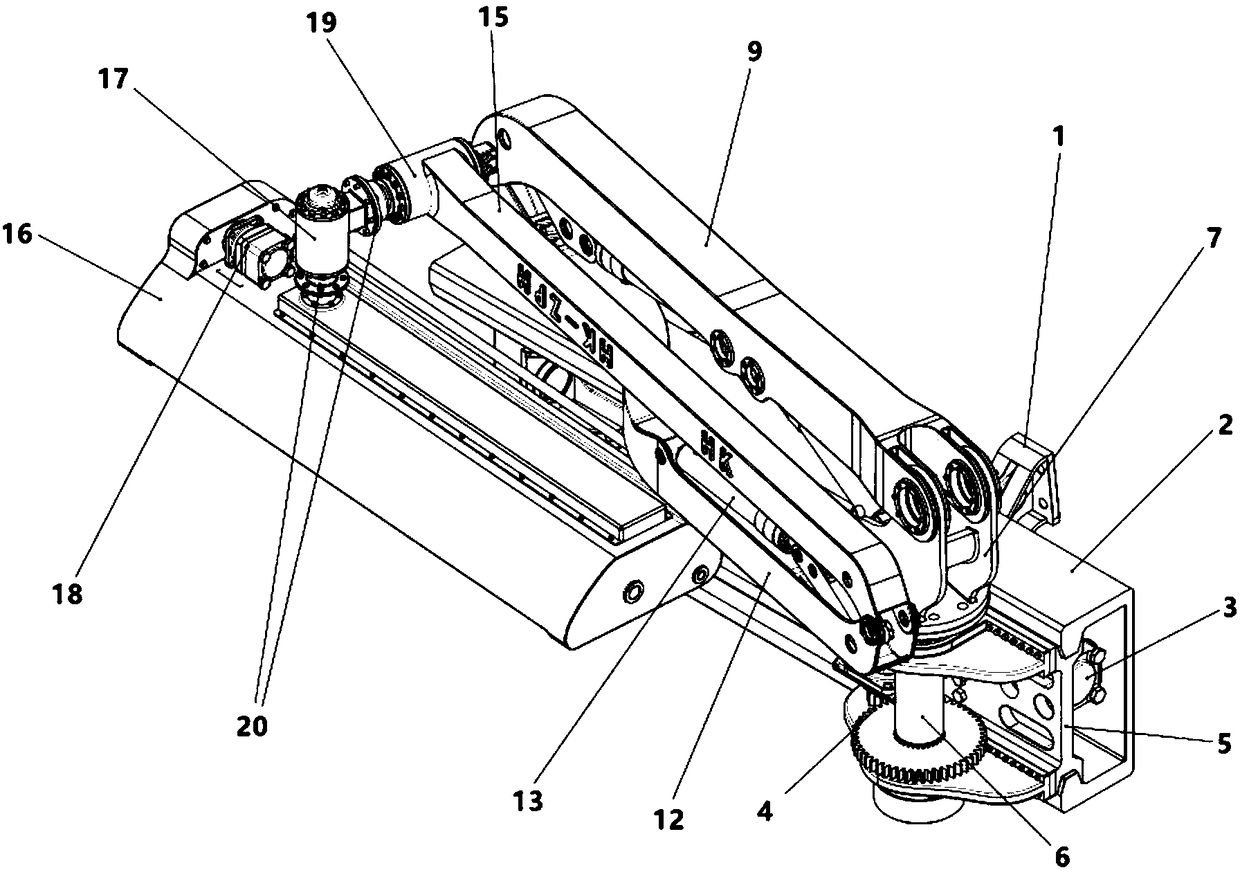

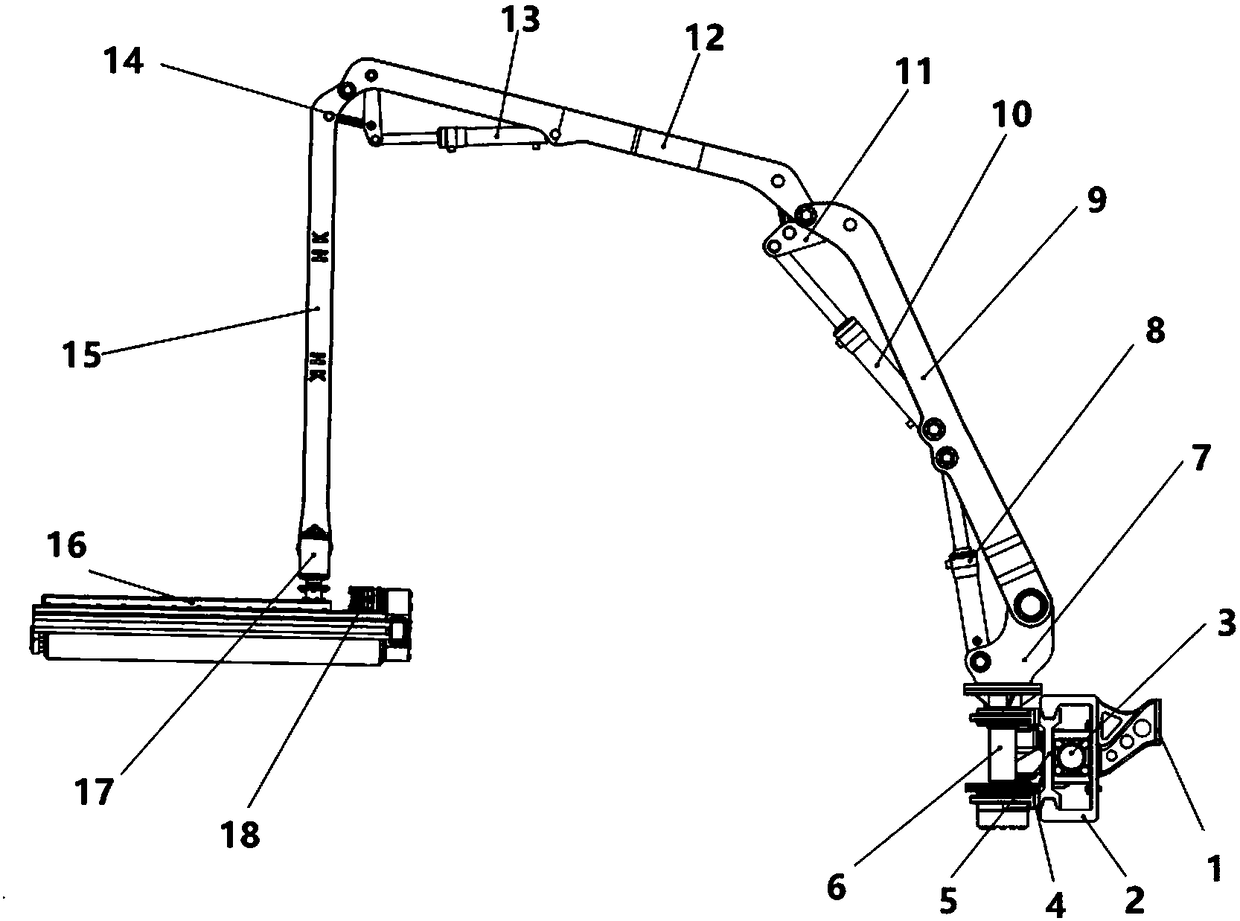

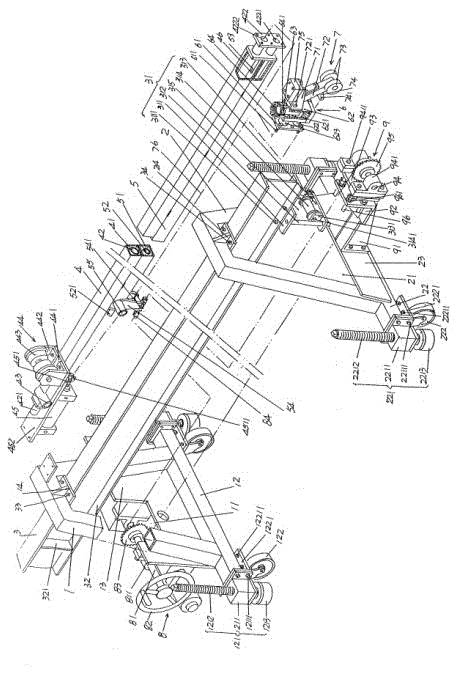

An industrial robot for material selection, clamping and handling in forging industry

InactiveCN103213839BLarge working radiusRealize telescopic swingConveyor partsDrive shaftEngineering

The invention discloses a sorting, clamping and conveying industrial robot applied to forging industry. The sorting, clamping and conveying industrial robot is characterized by comprising a rotary base, a large arm, a small arm, a material sucking and clamping device, a large arm driving mechanism and a small arm driving mechanism, wherein the large arm is arranged on the rotary base, the small arm is arranged on the head of the large arm, and a workpiece clamping device is arranged on the small arm; and the large arm is driven by the large arm driving mechanism to swing along a large arm transmission shaft, and the small arm is driven by the small arm driving mechanism to swing along a small arm transmission shaft. The sorting, clamping and conveying industrial robot disclosed by the invention, can realize the telescopic swing of the large arm and the small arm, the automatic sorting and the operation of clamping a workpiece into an inlet of a diathermanous furnace through the large arm arranged on the rotary base and the small arm arranged on the large arm, has the advantages of large working radius, high working efficiency, low noise and the like, saves a great amount of labors, has a simple structure, and is reliable in working and lower in manufacturing and maintenance costs.

Owner:钟昀晖

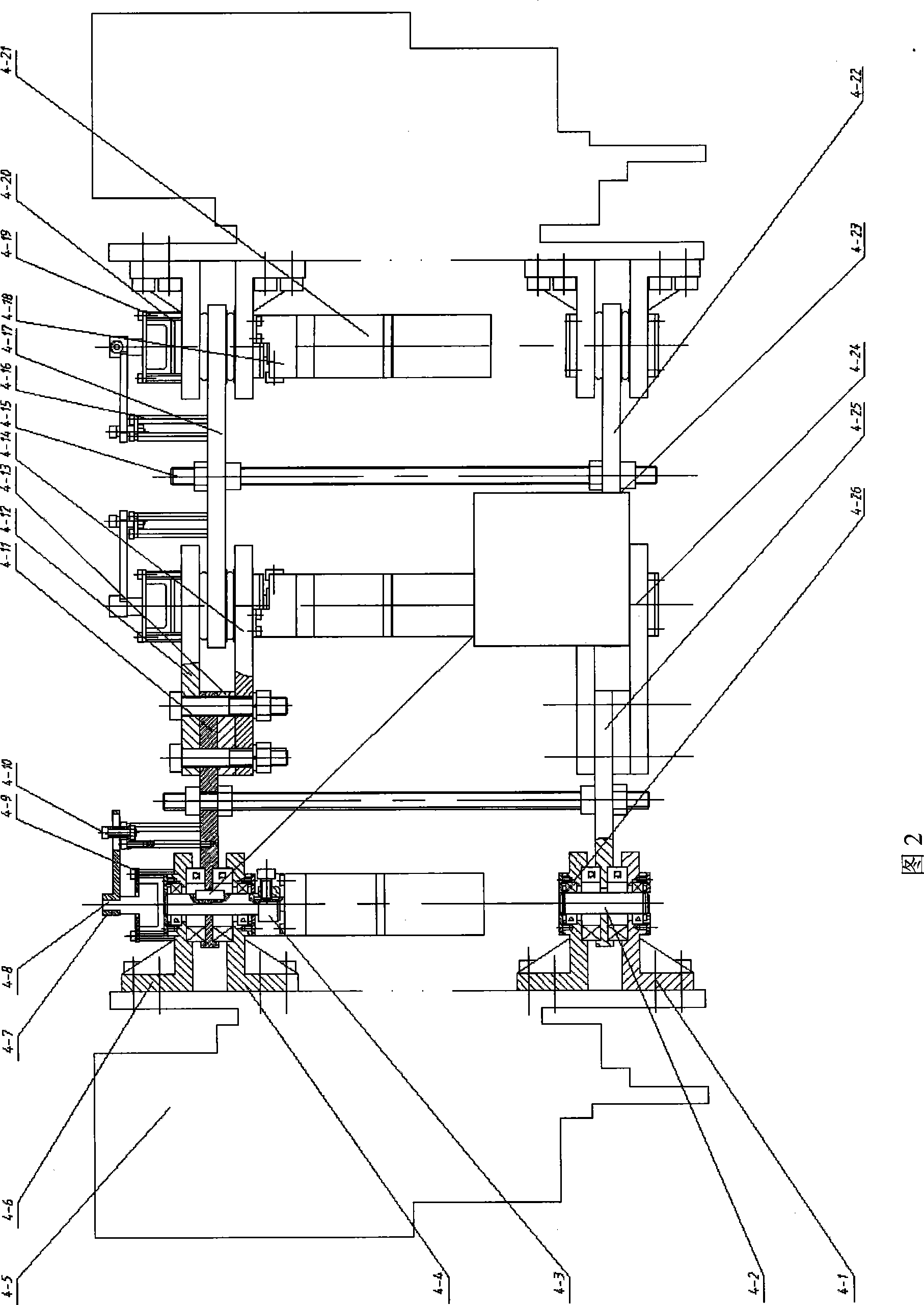

Automatic torpedo ladle inserting and pulling system and inserting and pulling method

PendingCN114256718ASatisfy the work of automatic plugging and unpluggingImprove flexibilityMelt-holding vesselsCoupling device engaging/disengagingControl systemStructural engineering

The invention discloses an automatic torpedo ladle inserting and pulling system and an inserting and pulling method. The torpedo ladle plug comprises a torpedo ladle plug female head, wherein the torpedo ladle plug female head is mounted on a torpedo ladle; the device comprises a torpedo ladle plug male head, the torpedo ladle plug male head is installed at the execution end of a plugging mechanism, the fixed end of the plugging mechanism is connected with an industrial robot system through a connecting flange, and a laser vision system is installed on the connecting flange. The industrial robot system comprises a robot body, the robot body is connected with the control system through a connecting cable, and the control system is connected with the demonstrator. Laser vision is adopted to detect the position of the plug male head on the torpedo tank car, and automatic plugging power taking of the torpedo tank car can be achieved in cooperation with a robot and a specially-designed plugging mechanism; the robot is good in flexibility and can execute complex actions; the stability is high, the device can be suitable for severe work, and the maintenance cost and workload are low; the working radius is large, and automatic plugging work of various torpedo tank cars can be met.

Owner:湖南严格智能技术有限公司

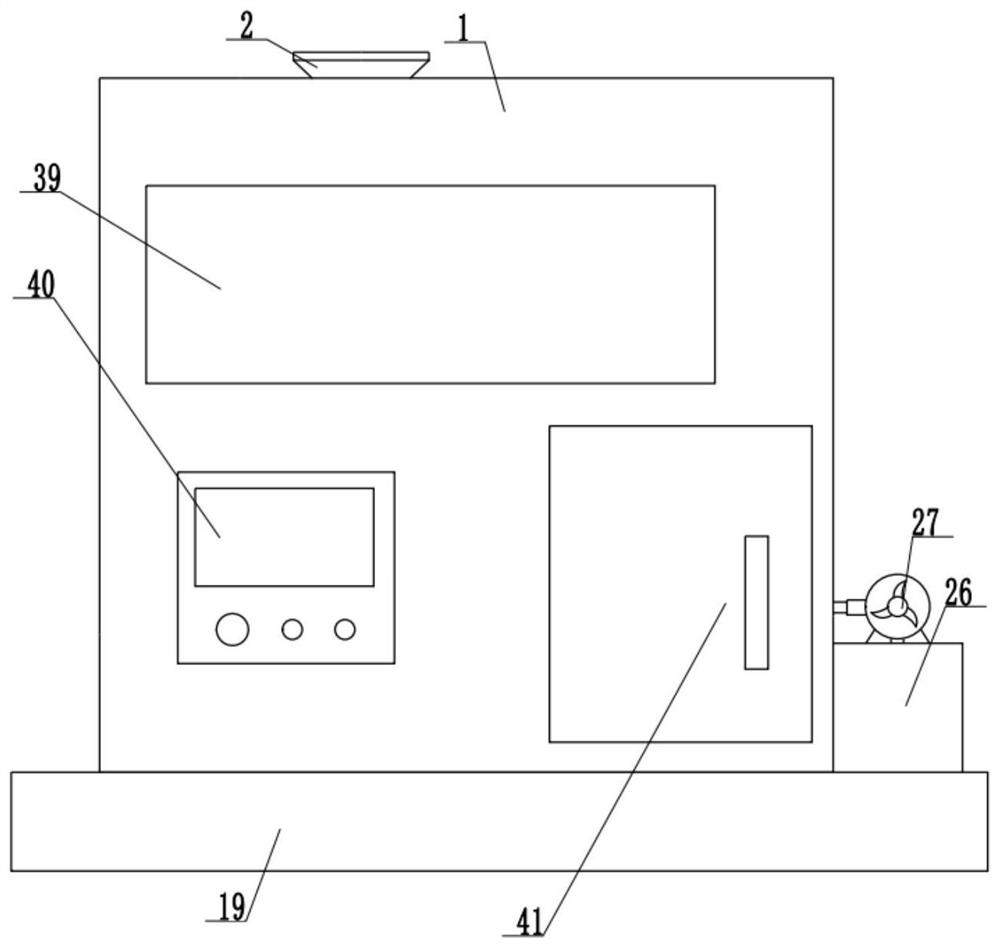

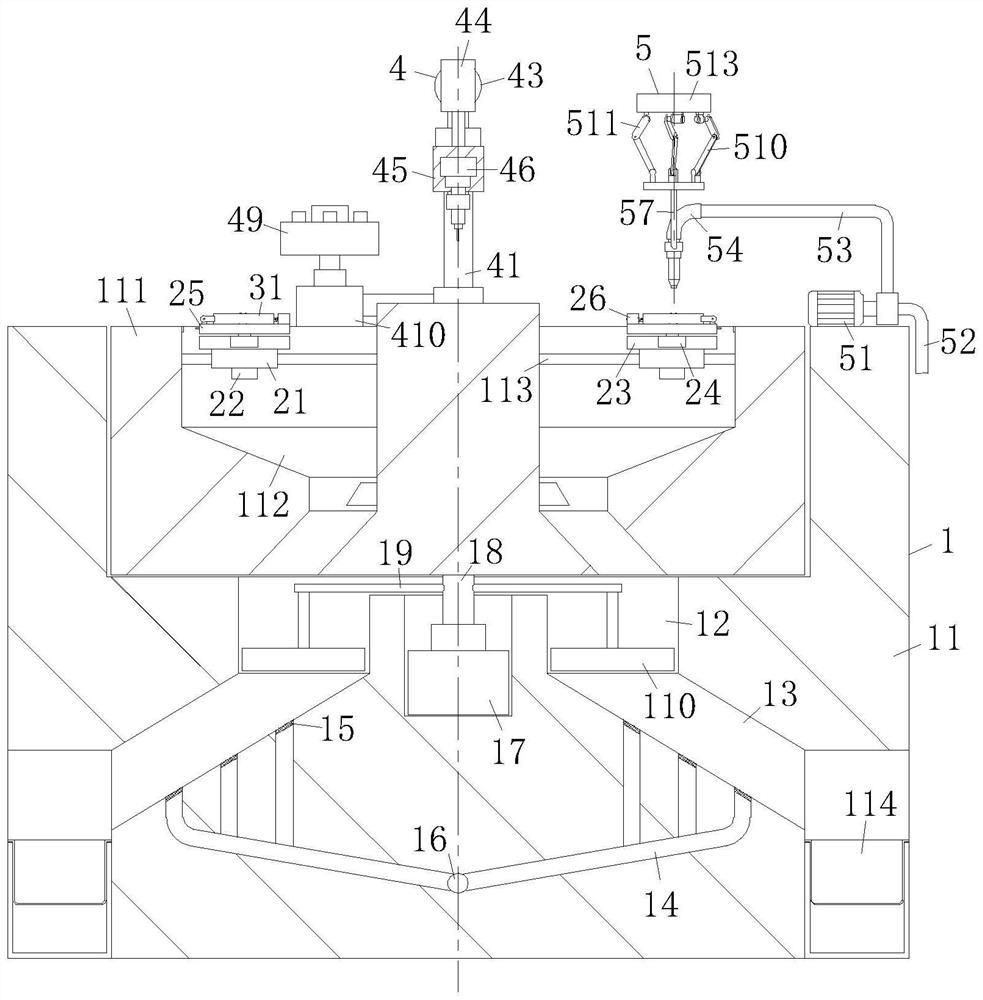

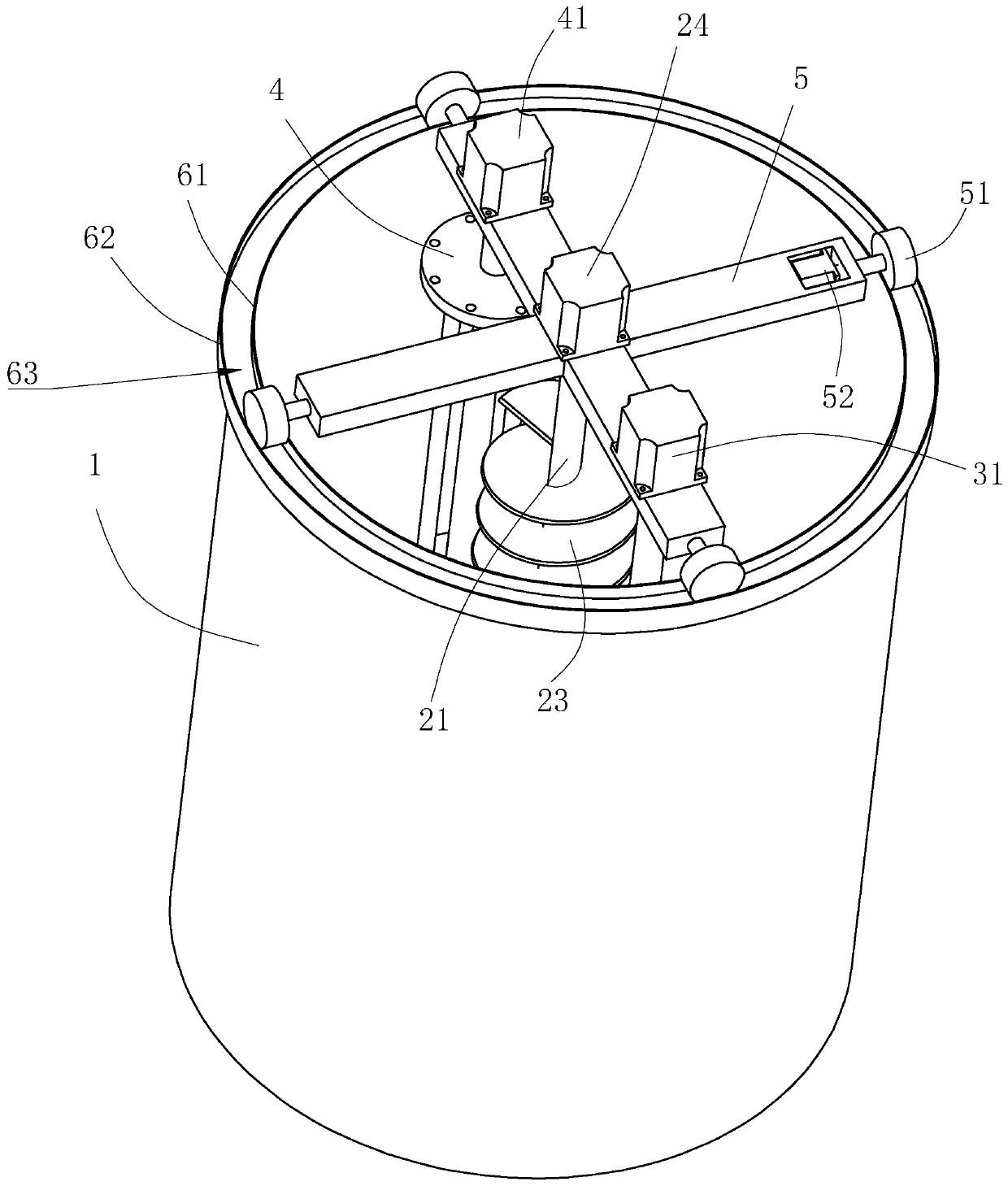

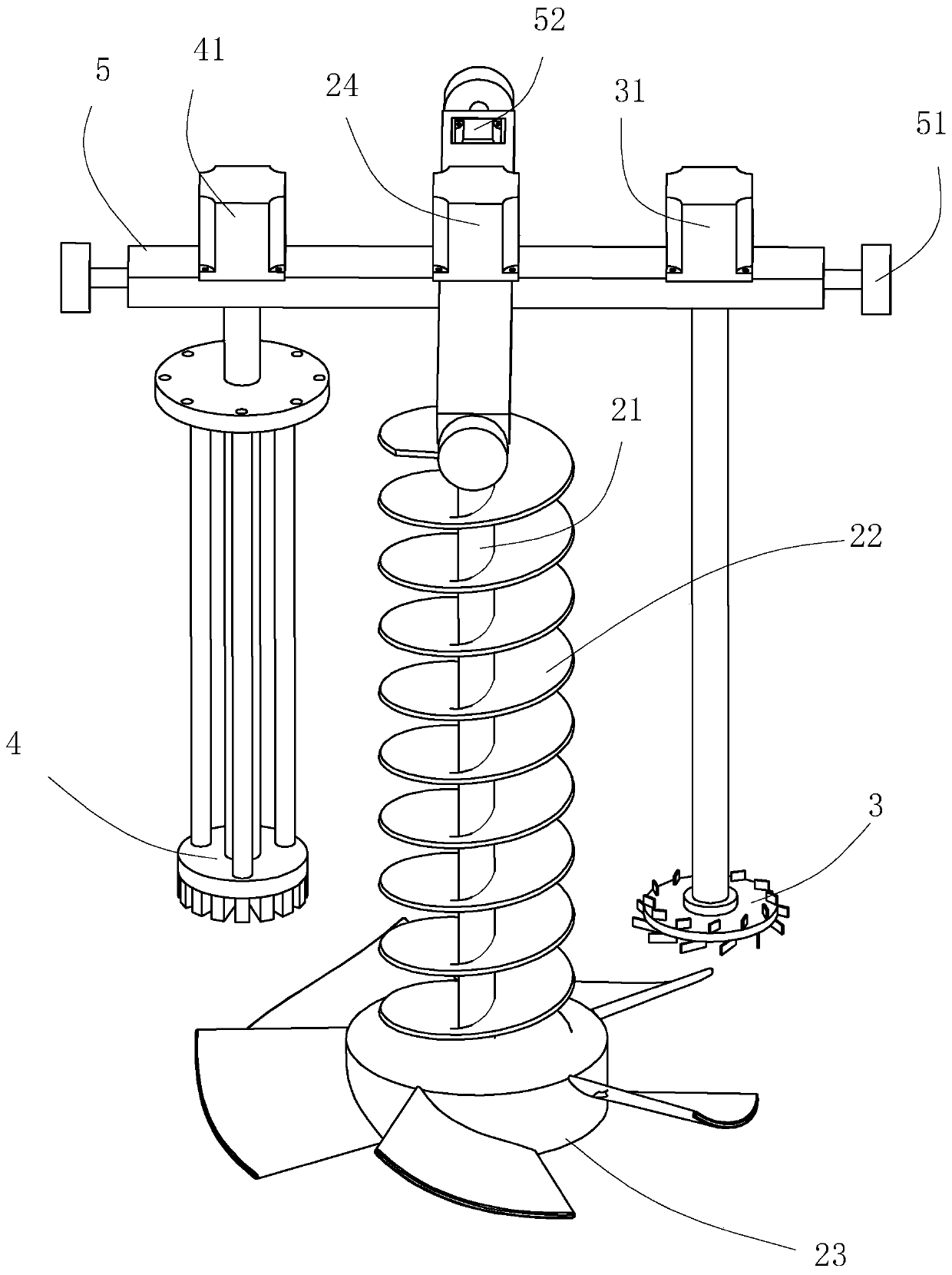

Printing water-based coating varnish manufacturing apparatus

PendingCN110090577AShorten the timeLow costTransportation and packagingMixing methodsWater basedPulp and paper industry

The invention relates to a printing water-based coating varnish manufacturing apparatus. The apparatus comprises a production kettle, a stirring device driven by a first motor, a dispersing machine driven by a second motor and an emulsifying machine driven by a third motor are arranged in the production kettle, the opening of the production kettle is provided with a heavy frame, and the heavy frame is used for hanging the stirring device, the dispersing machine and the emulsifying machine. The stirring device can stir a plurality of raw materials poured into the production kettle, and the dispersing machine and the emulsifying machine can disperse and emulsify the mixed raw materials to avoid distribution dispersing and emulsifying of the raw materials in multiple steps, so the forming time of the water-based varnish is greatly shortened, and the production efficiency is increased. The opening of the production kettle is provided with the heavy frame for hanging the stirring device, the dispersing machine and the emulsifying machine, so the heavy frame makes the stirring device, the dispersing machine and the emulsifying machine extend into the production kettle for production working.

Owner:YONGLIAN PRINTING CONSUMABLES SHENZHEN

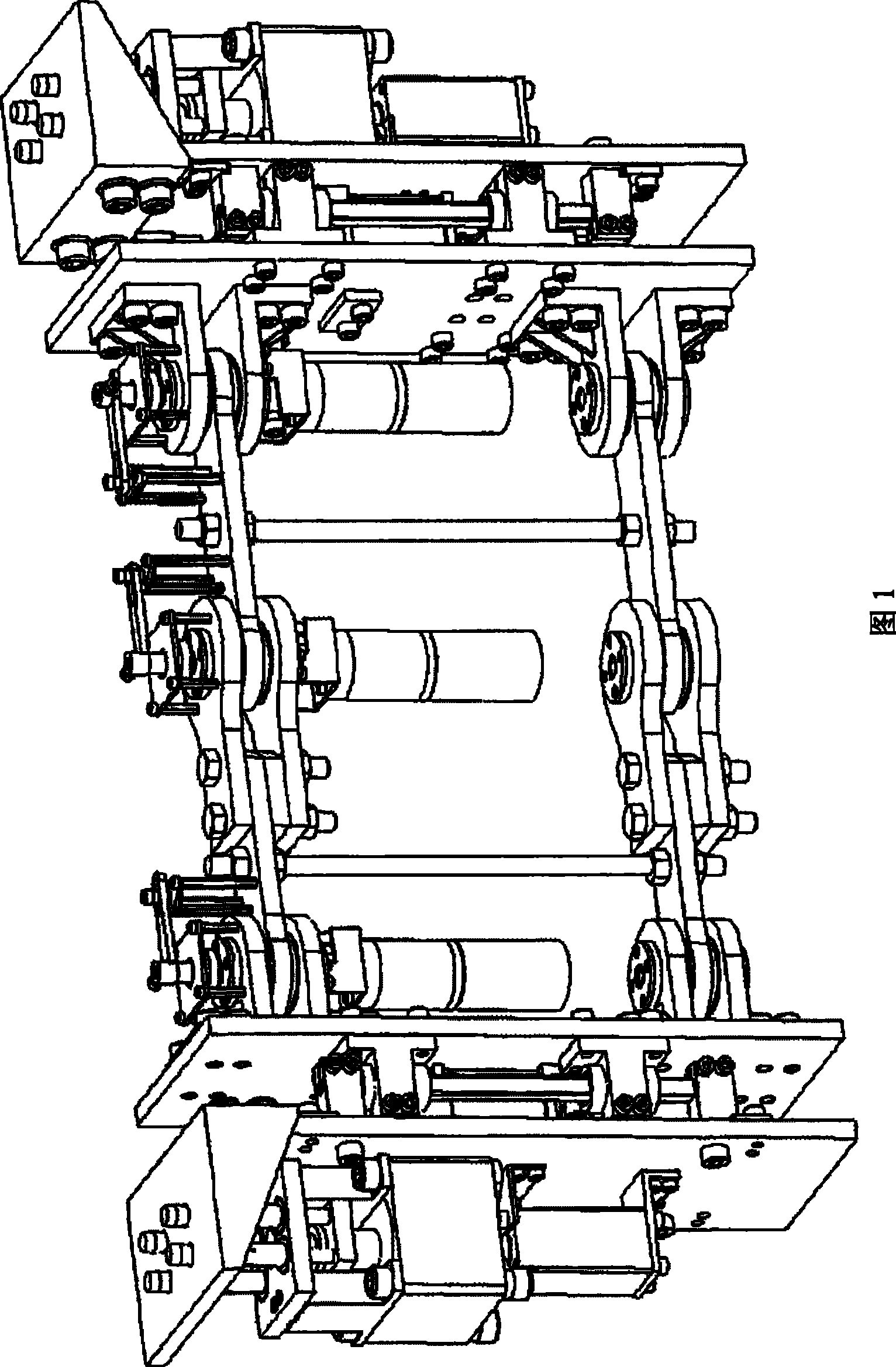

Multi-purpose afforestation maintenance mechanical device

ActiveCN108466282ASolve the problem of quickly changing different pruning knivesReduce use costGripping headsClimate change adaptationThree levelModularity

The invention relates to a multi-purpose afforestation maintenance mechanical device. The device is provided with working accessory heads with different functions. The working accessory heads of modularized design are flexibly replaced according to different requirements of working projects, and the functions of hedgerow shape clipping, lawn clipping, pesticide spraying, advertising board cleaning, guard bar cleaning, floor cleaning, twig pruning and the like can be achieved; the single device can be used for multiple purposes; the use cost is lowered; and work efficiency is improved. The device is provided with three levels of mechanical arms, two rotating platforms and a sliding platform, and therefore, the large working radius and more working postures can be achieved; meanwhile, the three levels of mechanical arms of the device can be folded, the small initial state size can be achieved, the occupied space of equipment is reduced, the device is more convenient to transport, and theconvenient and fast transportation requirement for cross-regional operation is met; in addition, fully-hydraulic drive is adopted, and noise generated in the working process is avoided to a great extent; and the device can be mounted by being matched with different types of carrying tools such as a light truck and a large agricultural tractor, and practicability of the device is improved.

Owner:DALIAN JIAOTONG UNIVERSITY

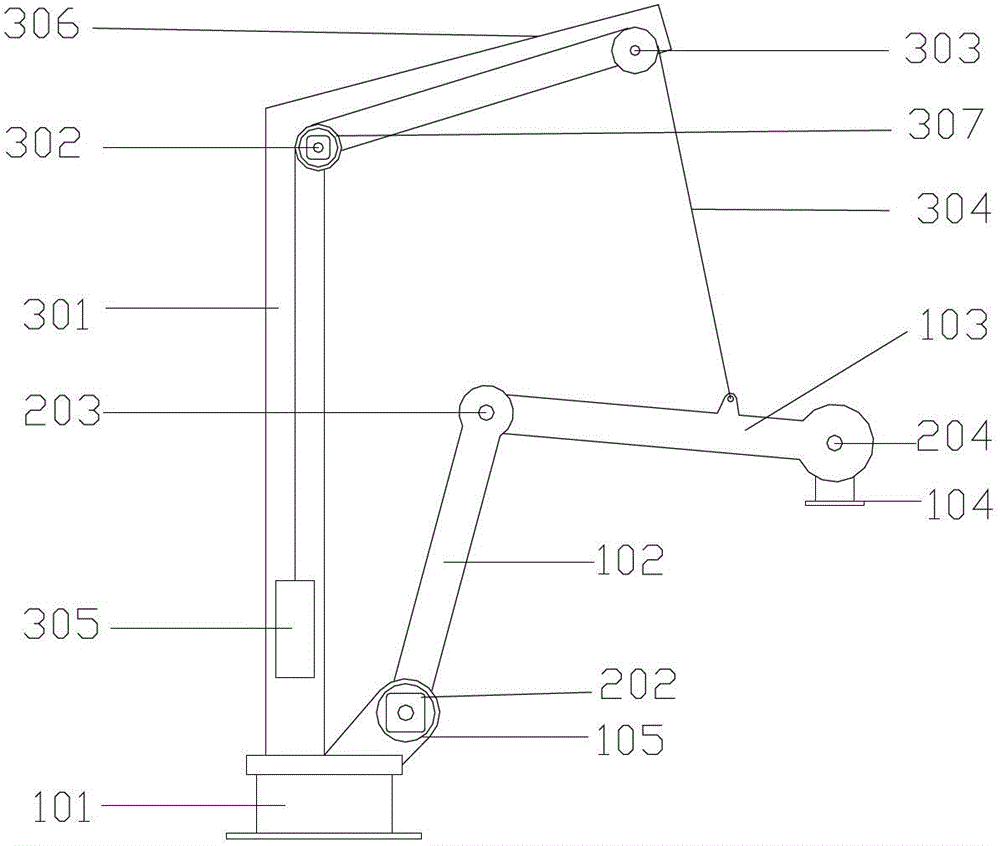

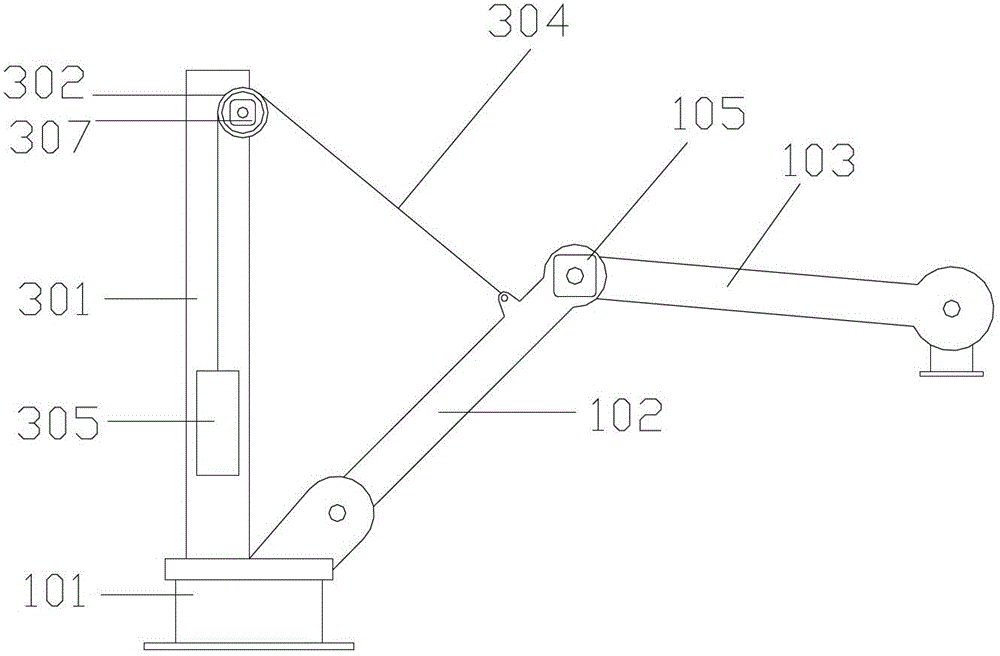

A robot driving structure

ActiveCN103419189BReduce structural strengthLight weightProgramme-controlled manipulatorDrive wheelControl theory

A robot driving structure has a base (101), a first arm (102) hinged to the base (101), a second arm (103) hinged to the first arm (102), at least two servo power units (105, 307), and a driving wheel (302) and a flexible rope (304) which are arranged on the base (101). The driving wheel (302) is connected to the base (101) by a supporting arm; one servo power unit (105) is provided between the base (101) and the first arm (102), and the driving wheel (302) is connected to another servo power unit (307). The flexible rope (304) is engaged with the driving wheel (302), and one end of the flexible rope (304) is connected to the second arm (103).Driven by the driving wheel (302), the flexible rope (304) pull the second arm (103) to swing, and the two servo power units (105, 307) drive the first arm (102) and the second arm (103) together to realize a coordination movement. The joint of the flexible rope (304) and the second arm (103) is located on the far end of the second arm (103), thus the driving force can be applied more directly, and the working accuracy and the load capacity of the driving structure can be improved.

Owner:范红兵

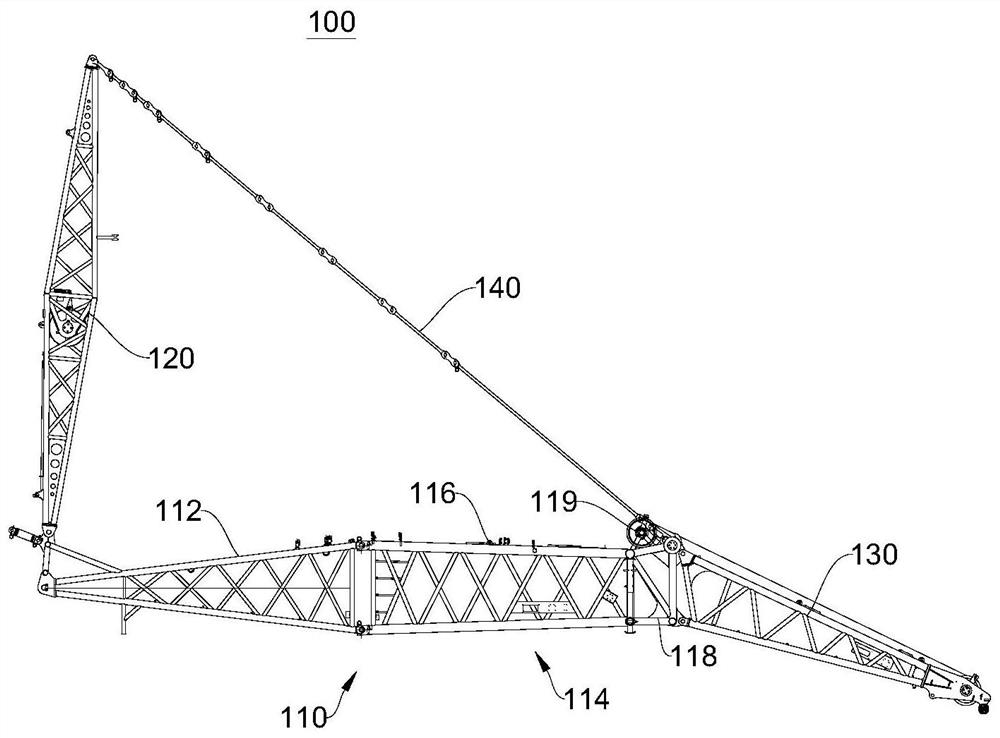

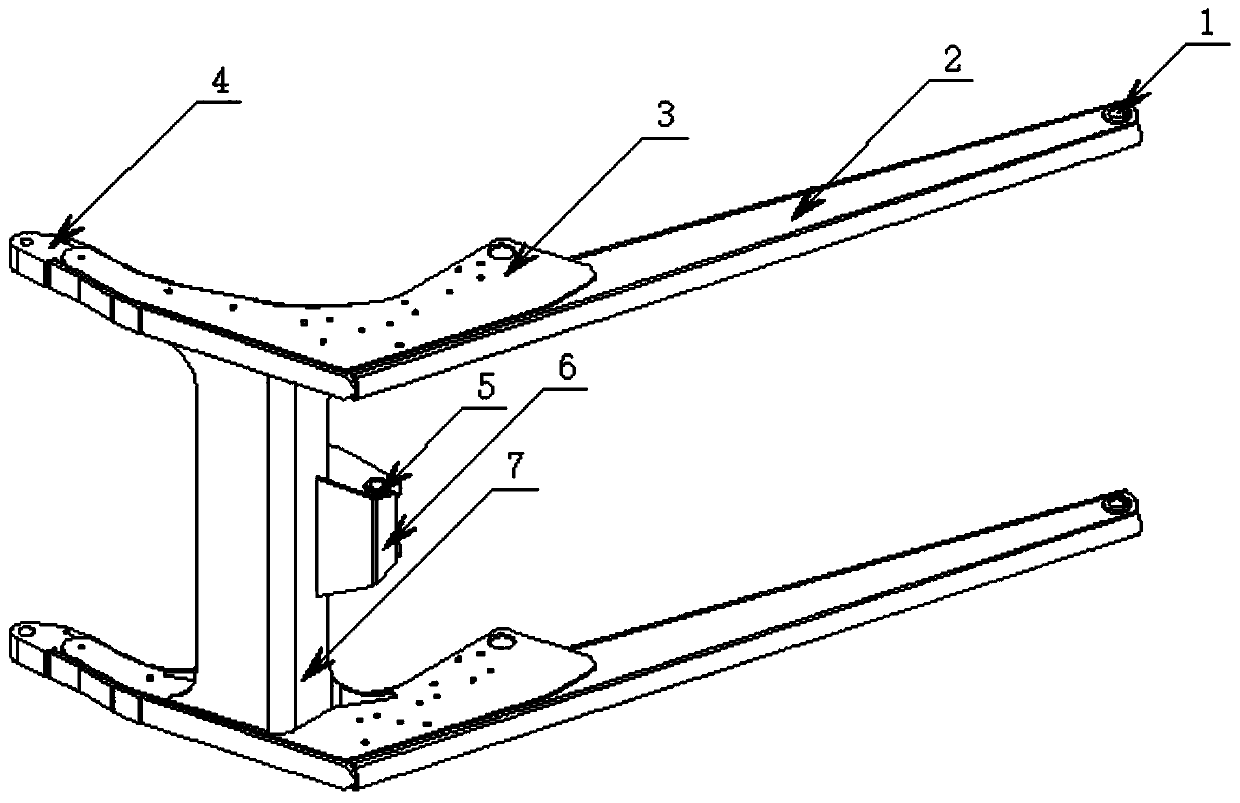

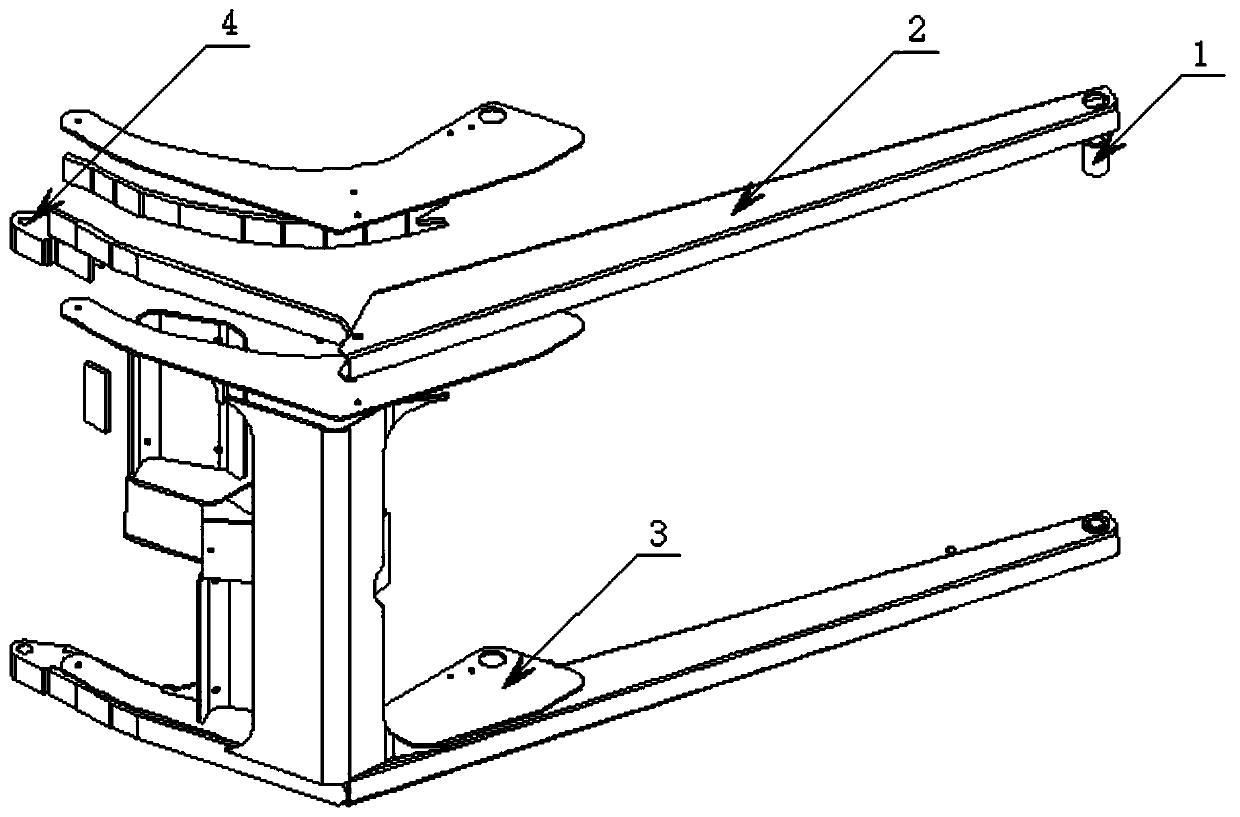

Connecting vice jib and engineering machinery

The embodiment of the invention provides a connecting vice jib and an engineering machinery, and relates to the technical field of engineering machinery. The connecting vice jib comprises a mast, a connecting arm, an extra arm and a pull plate, wherein one end of the mast is connected with one end of the connecting arm; one end of the pull plate is connected with one end, far away from the connecting arm, of the mast; the other end of the pull plate is connected with one end, far away from the mast, of the connecting arm; one end of the extra arm is connected with one end, far away from the mast, of the connecting arm; the other end of the extra arm is used for installing a lifting tackle; and the extra arm and the connecting arm are arranged to form an included angle. According to the connecting vice jib and the engineering machinery provided by the embodiment of the invention, the extra arm and the connecting arm are connected and are arranged to form the included angle, the extra arm is connected with the connecting arm so as to stretch out of the connecting arm in a suspension way, the extra arm and the connecting arm form a fixed included angle, and when the lifting tackle arranged on the extra arm lifts cargoes during work, the working radius is extended in the cargo lifting process since the extra arm and the connecting arm are arranged to form the included angle, so that the cargoes cannot collide the connecting arm, and the working stability of the connecting vice jib is improved.

Owner:ZHEJIANG SANY EQUIP

Sand blasting device

ActiveCN104259996BAvoid occupyingLarge working radiusAbrasive feedersAbrasive machine appurtenancesPipe waterSand blasting

Owner:苏州华威工程技术有限公司

Novel skid type loader lifting arm

The invention discloses a novel skid type loader lifting arm which comprises a lifting arm body composed of two carframe connecting shaft sleeves, two arm bodies, two side plates, two accessory connecting blocks, an oil cylinder connecting shaft sleeve, an oil cylinder protective plate and a connecting support. The lifting arm body is formed by welding all the parts. The carframe connecting shaftsleeves and the oil cylinder connecting shaft sleeve are each of an alloy high-strength steel structure. The arm body is arranged in an L shape. The lifting arm is provided with the accessory connecting blocks adopting the conical assembling hole structure, the accessory grasping force is increased, the stress of an oil cylinder of the lifting arm is concentrated, the overall stress is high, the working intensity is effectively increased, the hollow arm body structure is adopted, the strength of the arm body is ensured while the quality is effectively lowered, the working service life is prolonged, the size of the lifting arm is lowered while the working radius is effectively increased, the working applicability is wider, the lifting arm is connected in a welded mode, and the strength is increased.

Owner:合肥佳恩特机械制造有限公司

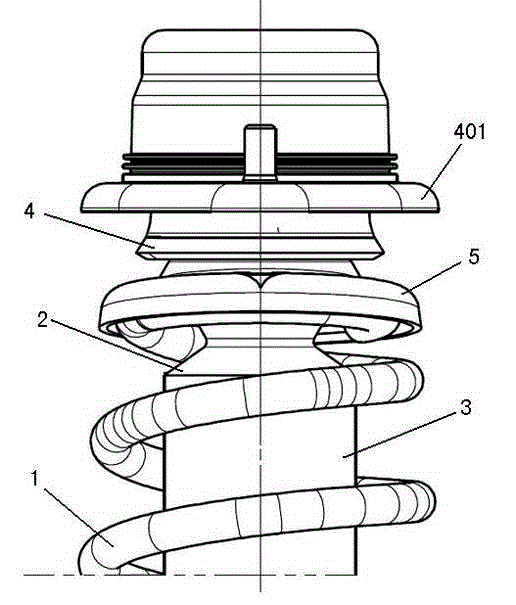

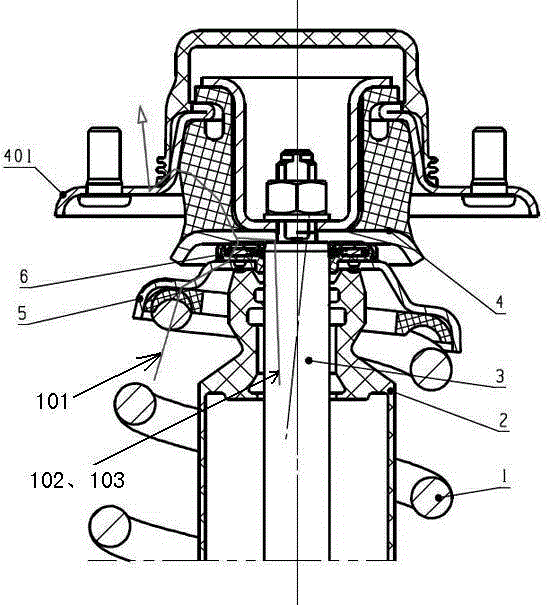

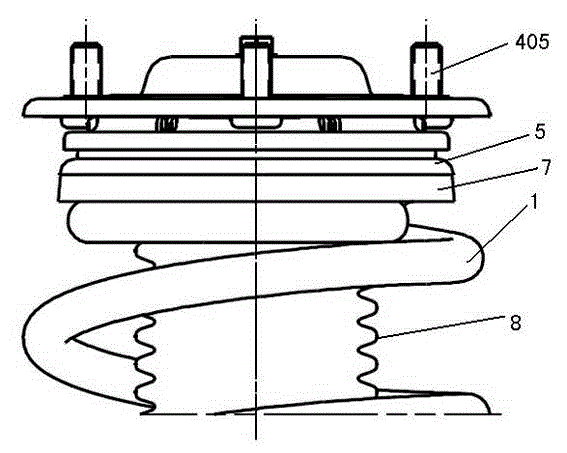

Separation buffering type shock absorber strut and automobile

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Unified control of multifunctional UAV swarms

ActiveCN106919183BLarge working radiusImprove battery lifePosition/course control in three dimensionsData informationUncrewed vehicle

The invention discloses a uniformly controlled multifunctional unmanned aerial vehicle group. The unmanned aerial vehicle group is provided with a plurality of unmanned aerial vehicles, and is characterized in that the unmanned aerial vehicles carry different working devices, so that different unmanned aerial vehicles can be selected when different tasks are executed. Each unmanned aerial vehicle carries a small number of working devices and is low in cost, so that the economic loss is within a controllable range even if the unmanned aerial vehicle runs into an accident and is damaged. In addition, data information is transferred through a ZigBee wireless module, and a plurality of ZigBee wireless modules form a network. The plurality of unmanned aerial vehicles are controlled by using a single device through a data transmission module, so that the manpower and material resource cost brought about by controlling a plurality of unmanned aerial vehicles is saved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

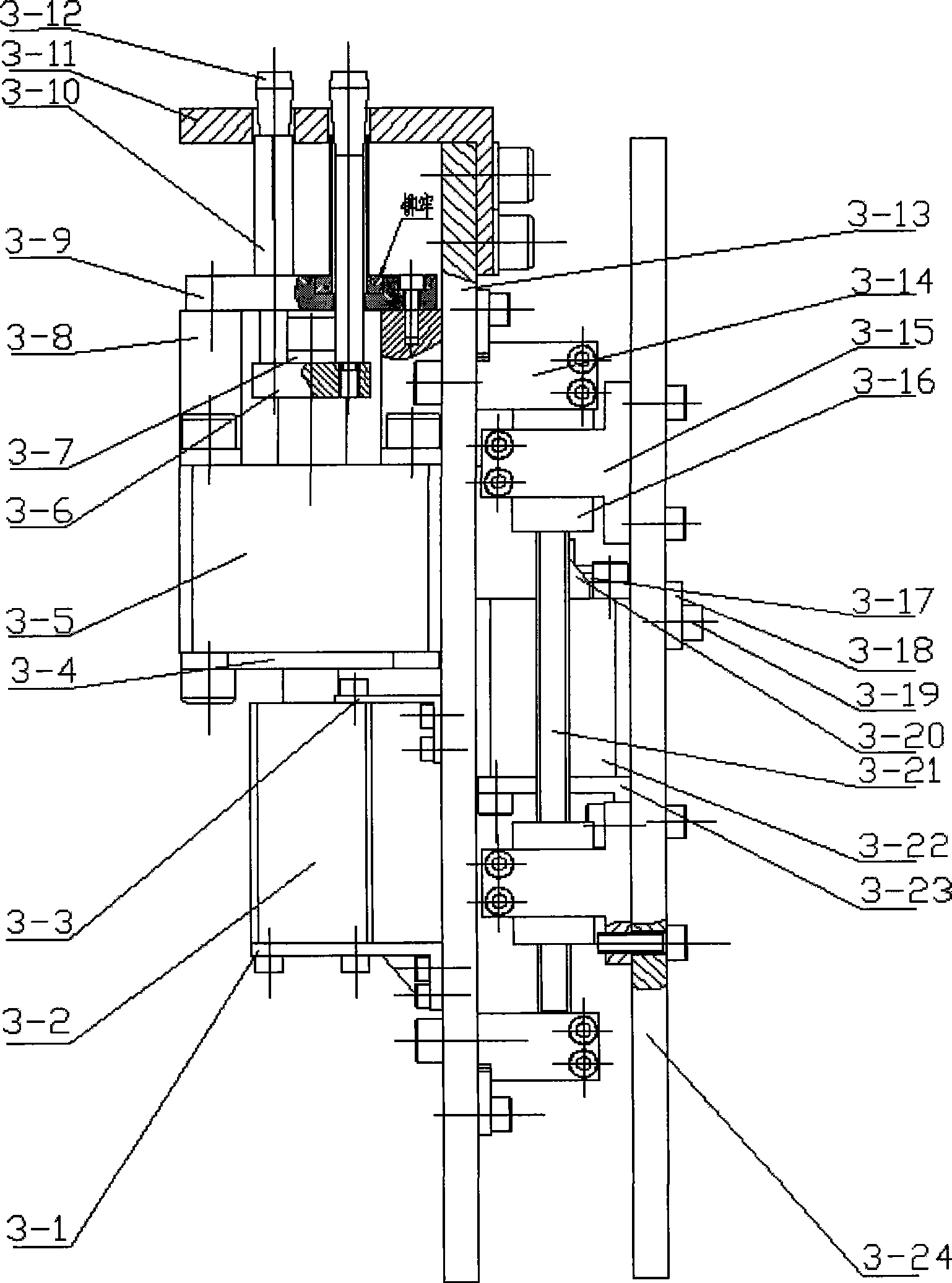

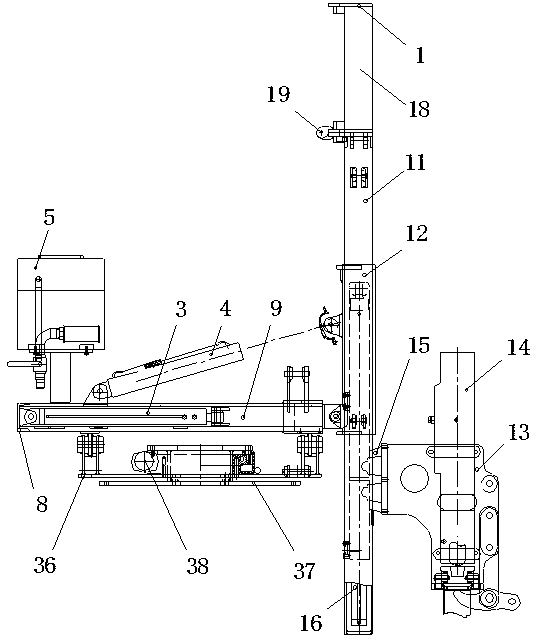

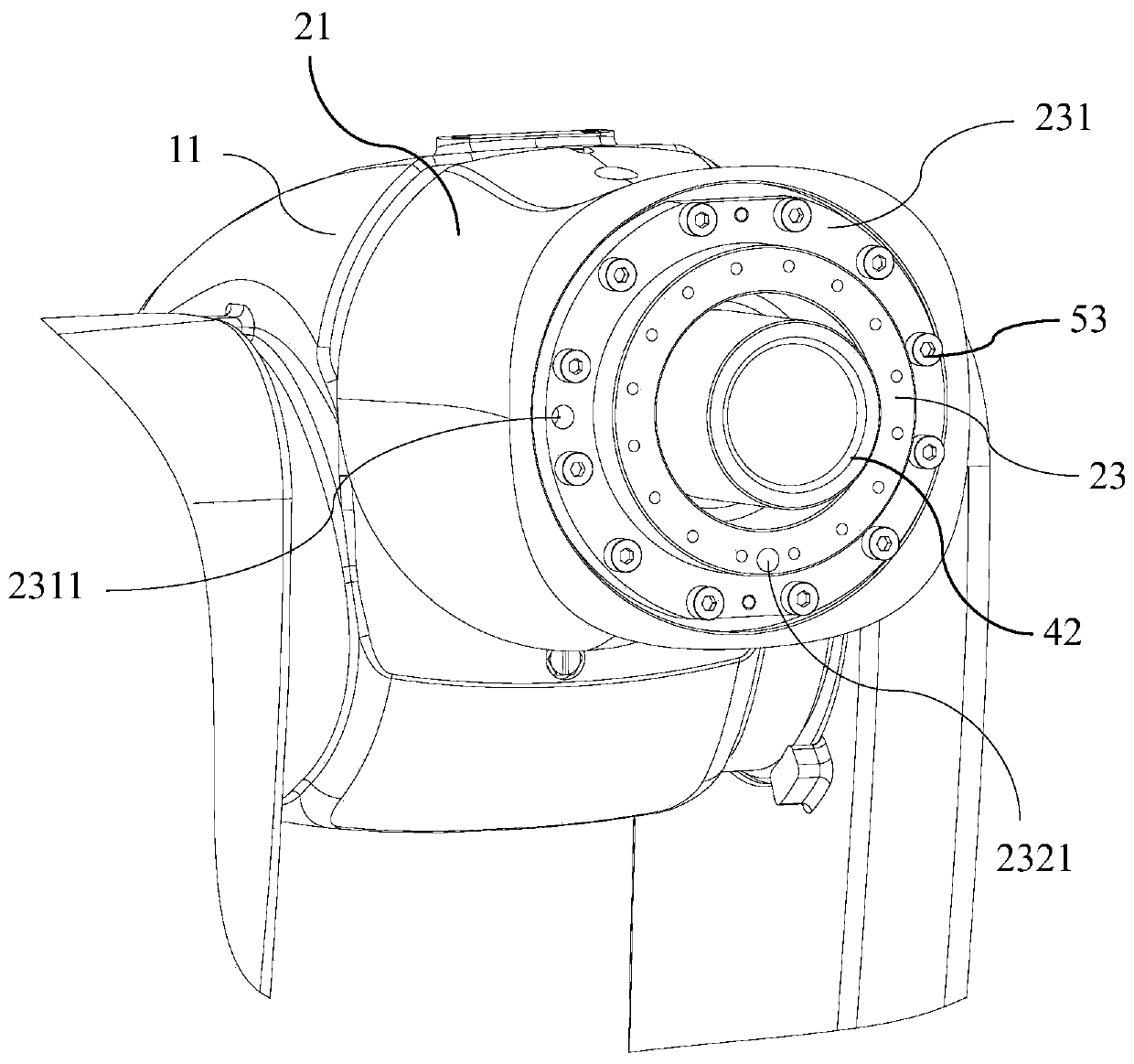

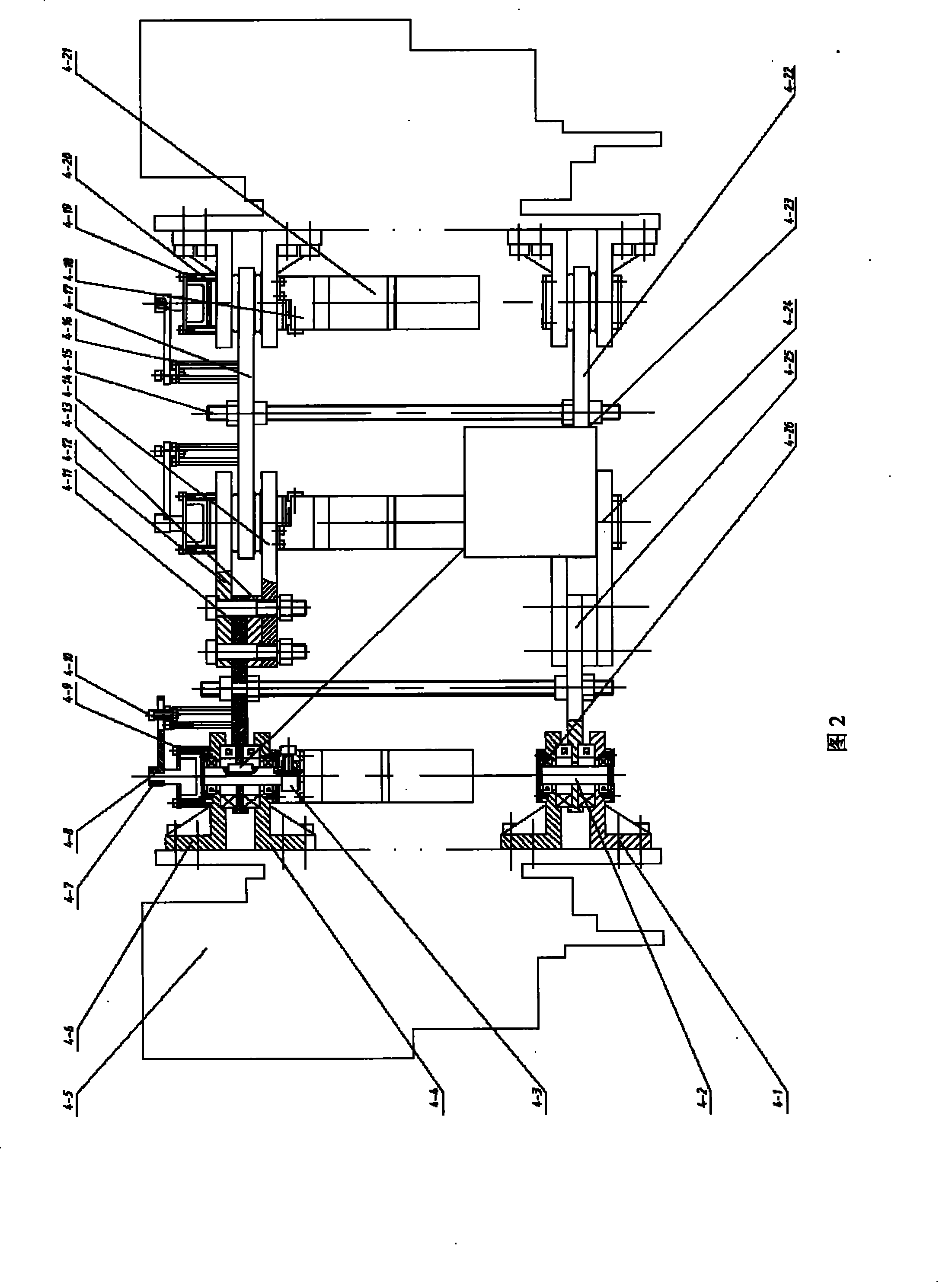

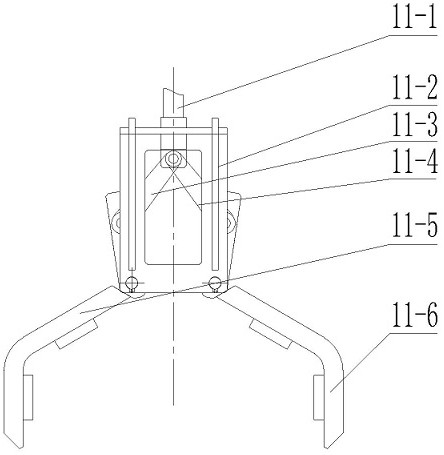

Mining drill rod changing manipulator

PendingCN113107400ALarge driving force per unit volumeLarge working radiusDrilling rodsDrilling casingsControl engineeringStructural engineering

The invention discloses a mining drill rod changing manipulator, and belongs to the technical field of mining mechanical equipment. The mining drill rod changing manipulator comprises a base, a slewing bearing, a lifting part, a translation part and a gripper assembly; the slewing bearing is arranged between the base and the lifting part; the lifting part is vertically arranged and is used for controlling the vertical lifting of the manipulator; the translation part is horizontally arranged and used for controlling the horizontal movement of the manipulator, and one end of the translation part is fixedly connected with the top end of the lifting part through a flange; the gripper assembly is vertically arranged and comprises a gripper opening and closing oil cylinder, a fixing frame, a four-bar mechanism, a left holding claw and a right holding claw; the fixing frame is arranged on the gripper opening and closing oil cylinder; the top end of the gripper opening and closing oil cylinder is in transmission connection with the translation part through a swing oil cylinder, and the bottom end of the gripper opening and closing oil cylinder is fixedly connected with the top end of the four-bar mechanism; the bottom end of the four-bar mechanism controls the left holding claw and the right holding claw correspondingly; and the top end of the left holding claw and the top end of the right holding claw are both hinged to the fixing frame. The problem that when drill rods are spliced and disassembled, operation of workers is difficult can be effectively solved.

Owner:徐州富锲机电科技有限公司

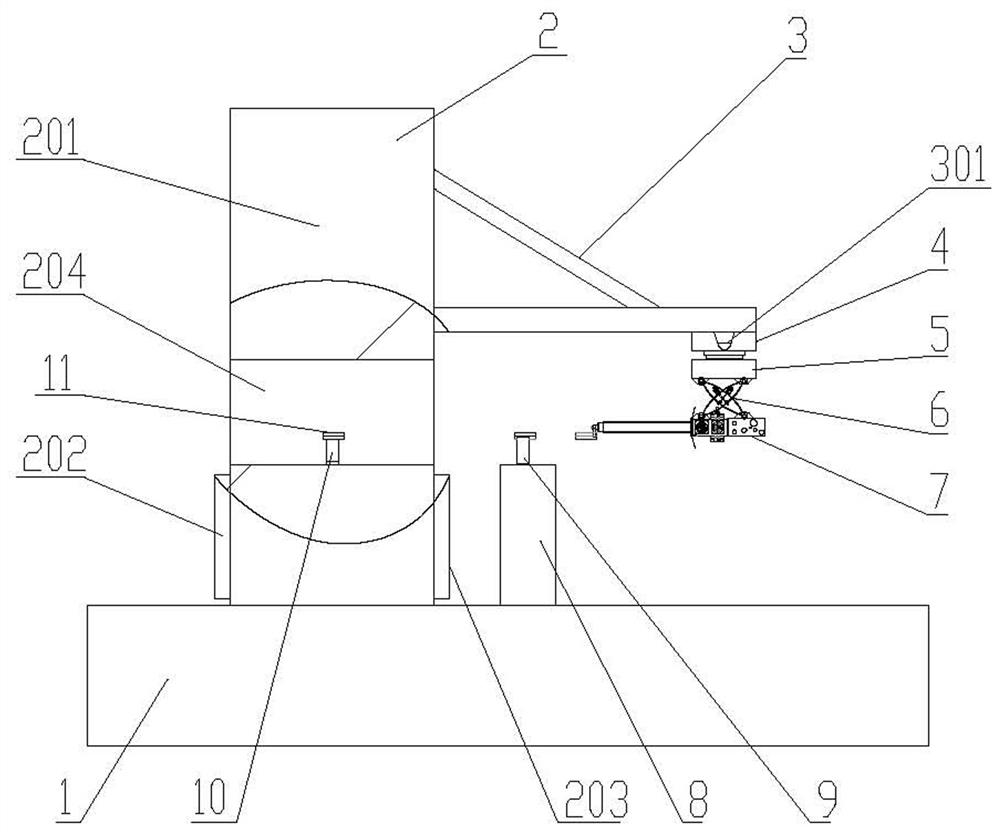

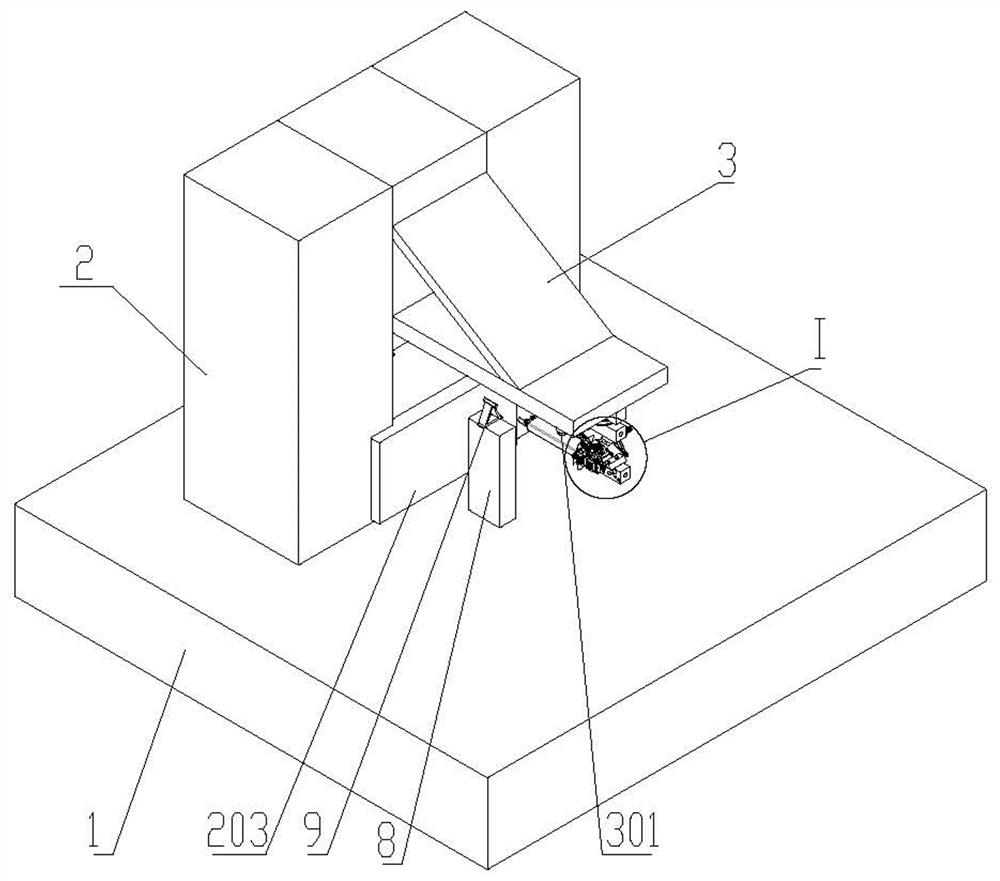

Sectional material clamping upside-down hanging table type equipment

PendingCN114111349ALarge working radiusImprove work efficiencyCharge manipulationForge furnacesSlide plateRotary stage

The invention relates to table type equipment, in particular to sectional material clamping inverted hanging table type equipment. Comprising a heat treatment furnace, a suspension support, a walking sliding plate, a rotating table, a flexible driving mechanism and a movable clamping platform, the suspension support is arranged above a feeding port of the heat treatment furnace, a linear module capable of outputting power in the direction close to or away from the feeding port is arranged at the bottom of the suspension support, and the walking sliding plate is connected with the linear module; a rotating table is arranged below the walking sliding plate, the lower portion of the rotating table is connected with the two sides of a movable clamping platform through two flexible driving mechanisms, the flexible driving mechanisms are used for adjusting the posture of the movable clamping platform, and the movable clamping platform is used for clamping profiles for feeding or discharging. The device has the advantages of large working radius, high working efficiency, low noise and the like, and a large amount of labor is saved; and the device is simple in structure, reliable in work and low in manufacturing cost and maintenance cost.

Owner:潍坊新松机器人自动化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com