Cleaning device

A technology for cleaning and cleaning mechanisms, applied in the direction of heating devices, solar thermal devices, cleaning methods and appliances, etc., can solve the problems of reducing the size or height of the brush holding device, and the inconspicuous height, so as to achieve safe operation and high The effect of operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

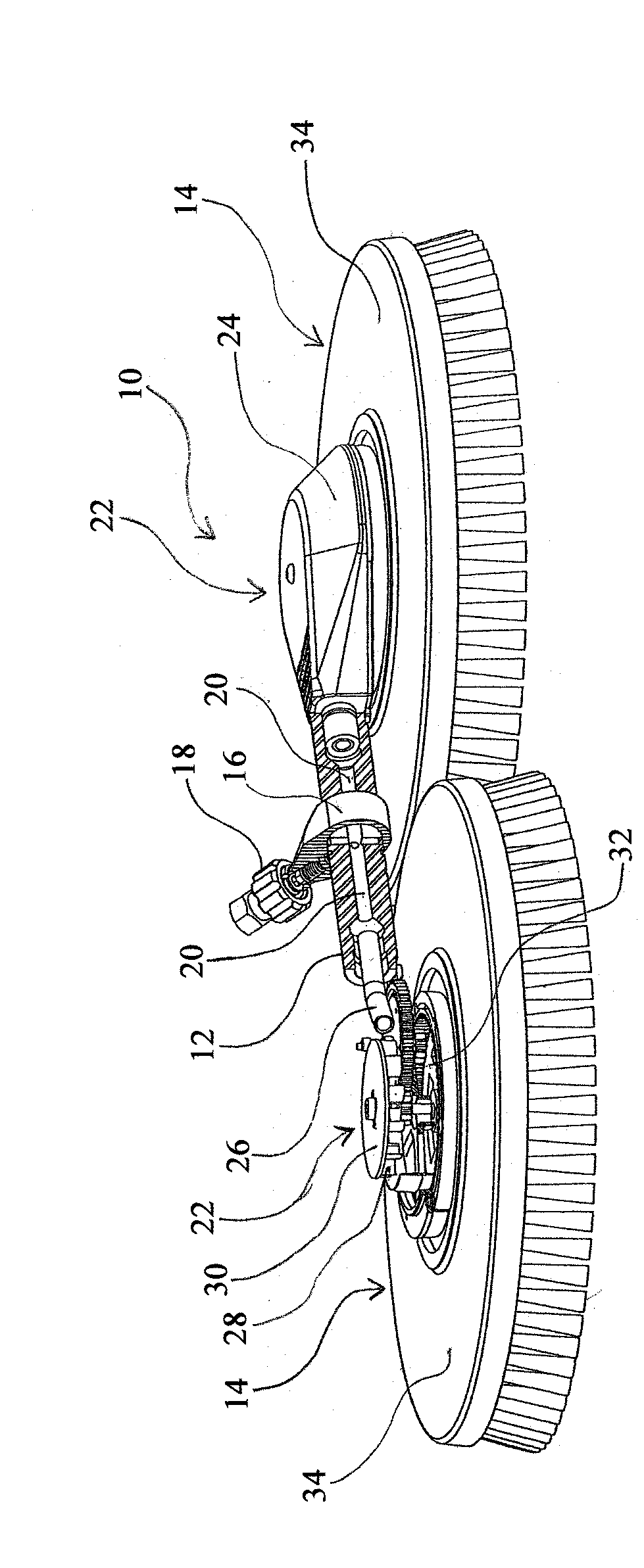

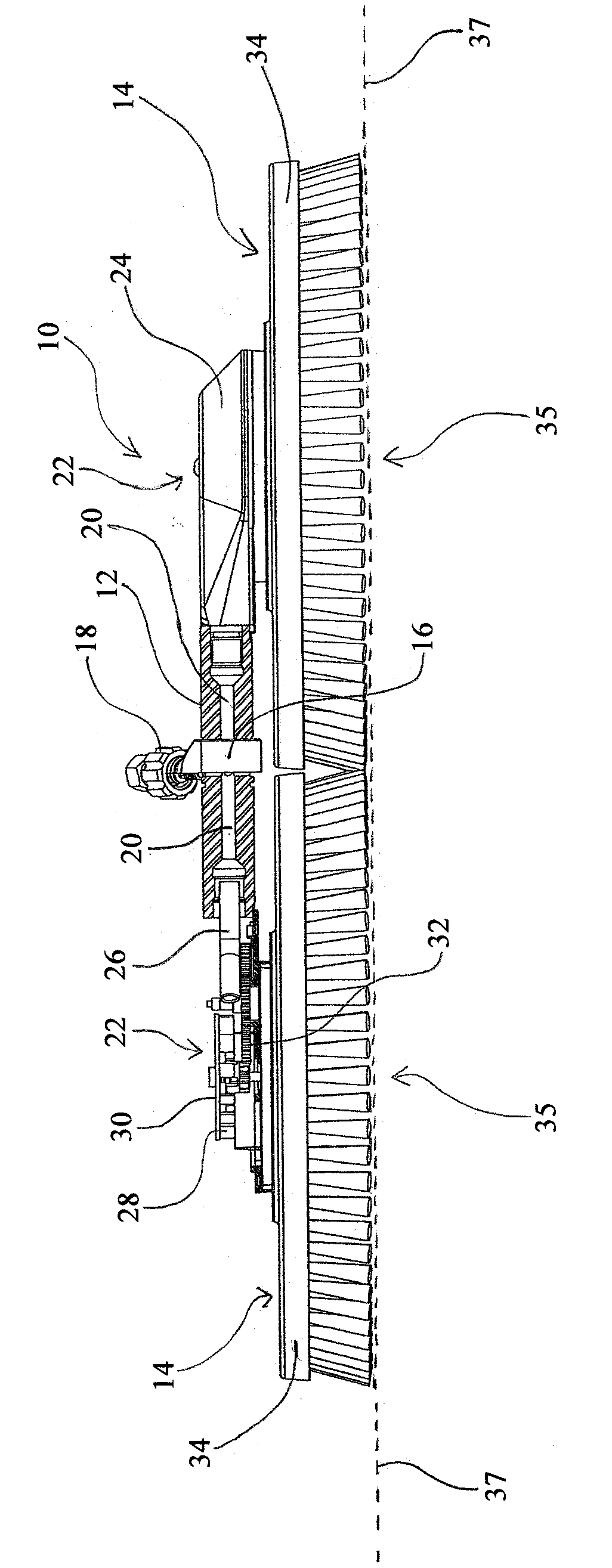

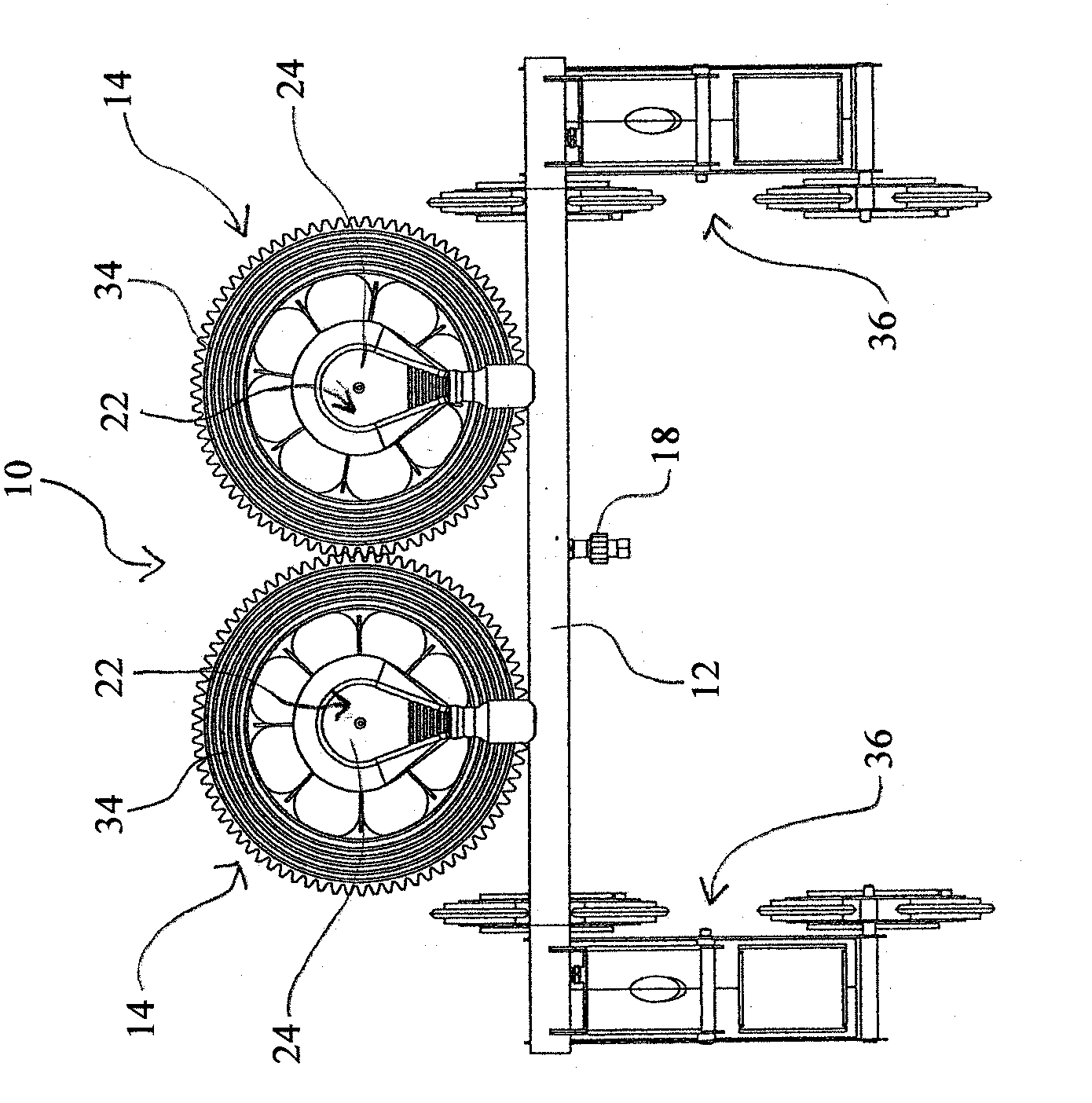

[0025] Such as Figure 1A and 1B As shown in , the device 10 according to the first embodiment of the present invention comprises an elongated frame 12 and two cleaning mechanisms 14 axially arranged on opposite ends of the frame 12 .

[0026] The support 12 has a hinge 16 centrally between the two cleaning elements 14 , into which a connecting element 18 is inserted which is designed for the connection of an external liquid supply line, in particular a hose or a nozzle. The inclination of the external liquid supply line can be adjusted relative to the working plane with the aid of the hinge 16 . The support 12 is provided with a channel extending in the axial direction on both sides of the connecting means 18 and serves as a liquid supply line 20 from the connecting means 18 to the two cleaning means 14 .

[0027] The cleaning means 14 is connected axially on the end side to a liquid supply line 20 . For this purpose, an axial outlet 26 is provided at both ends of the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com