Hand-held grinding machine especially storage cell powered hand-held grinding machine

A grinding tool and hand-held technology, applied in the field of hand-held grinding tools, can solve the problems of ergonomic design, ease of operation, adverse effects of manufacturing costs, large volume of components, large structural dimensions, etc., and achieve savings. Effects of structural length, low center of mass, high area machining capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

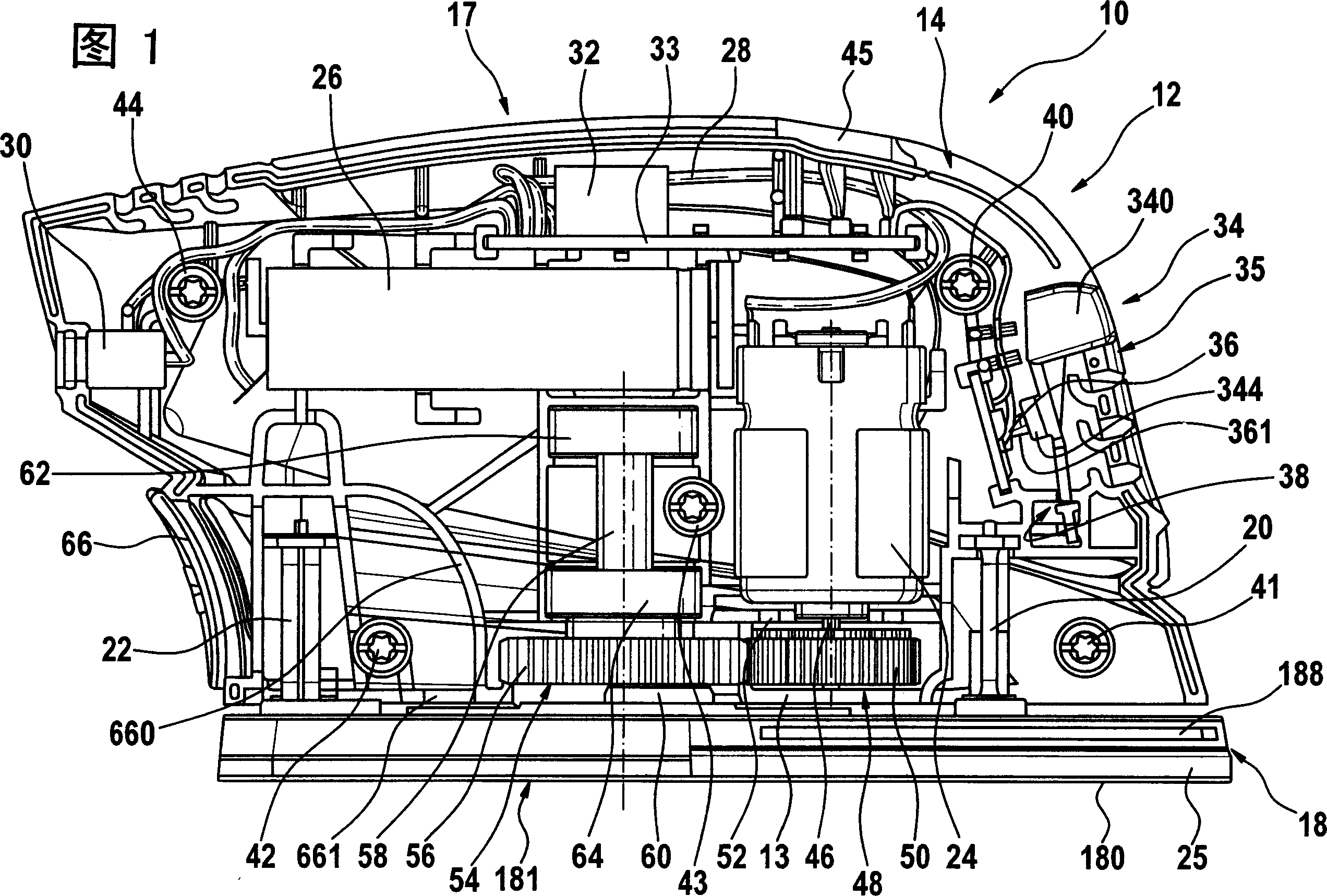

[0054] FIG. 1 shows a particularly small and compact battery-powered grinding machine 10 whose housing 12 is shown open by removing the right housing shell 16 and the line of sight can freely penetrate into the interior of the housing 12 or Said on the components in the housing shell 14 which will be described in detail below.

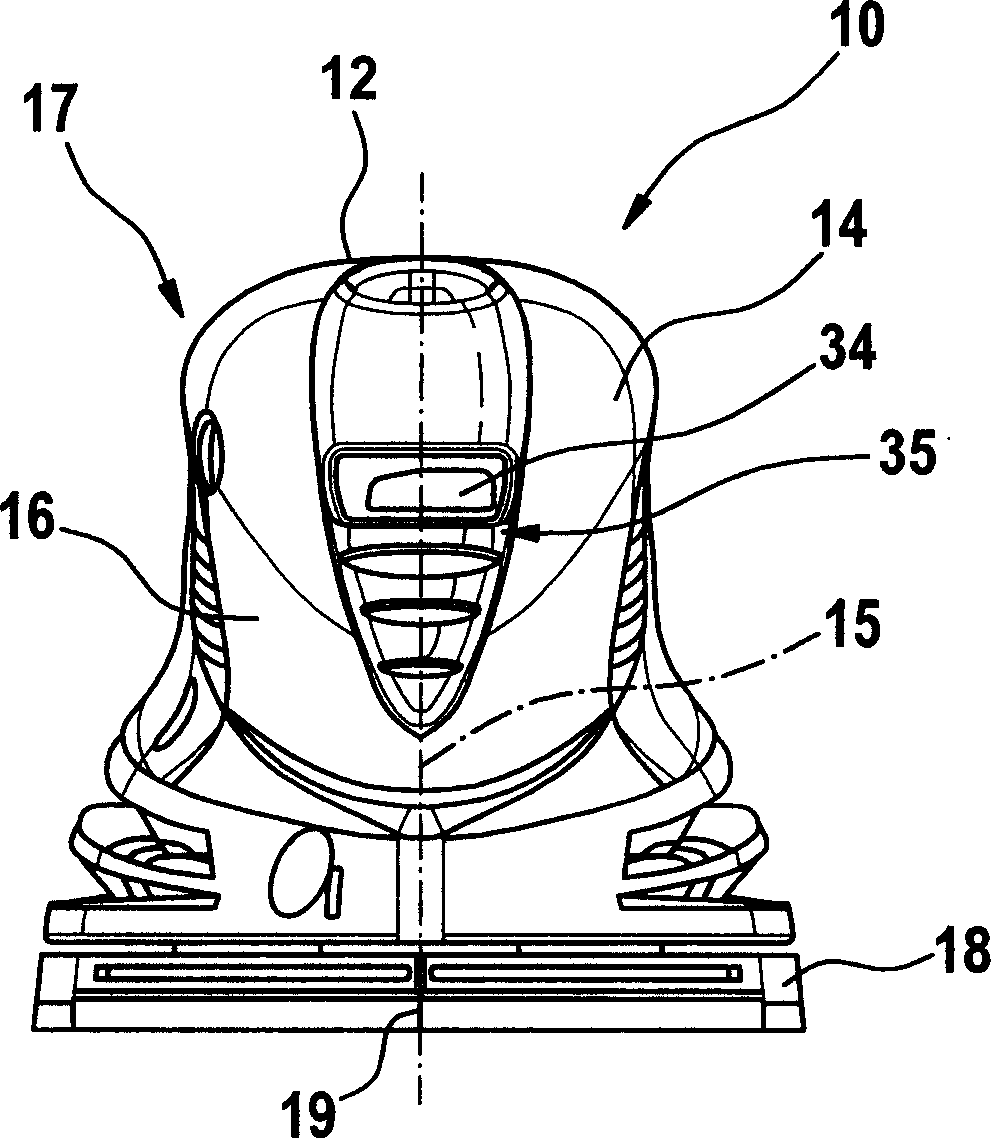

[0055] The housing 12 is formed from two half shells 14 , 16 which can join together in a central plane 15 in a sealingly supportive manner. For this reason five screws pass through some holes in the upper half shell 16 ( figure 2 ) are screwed into the five screw sleeves 40, 41, 42, 43, 44 of the lower half-shell 14 in order to fix the two to each other. The upper region of the housing 12 forms a curved handle region which can also be comfortably held by small hands.

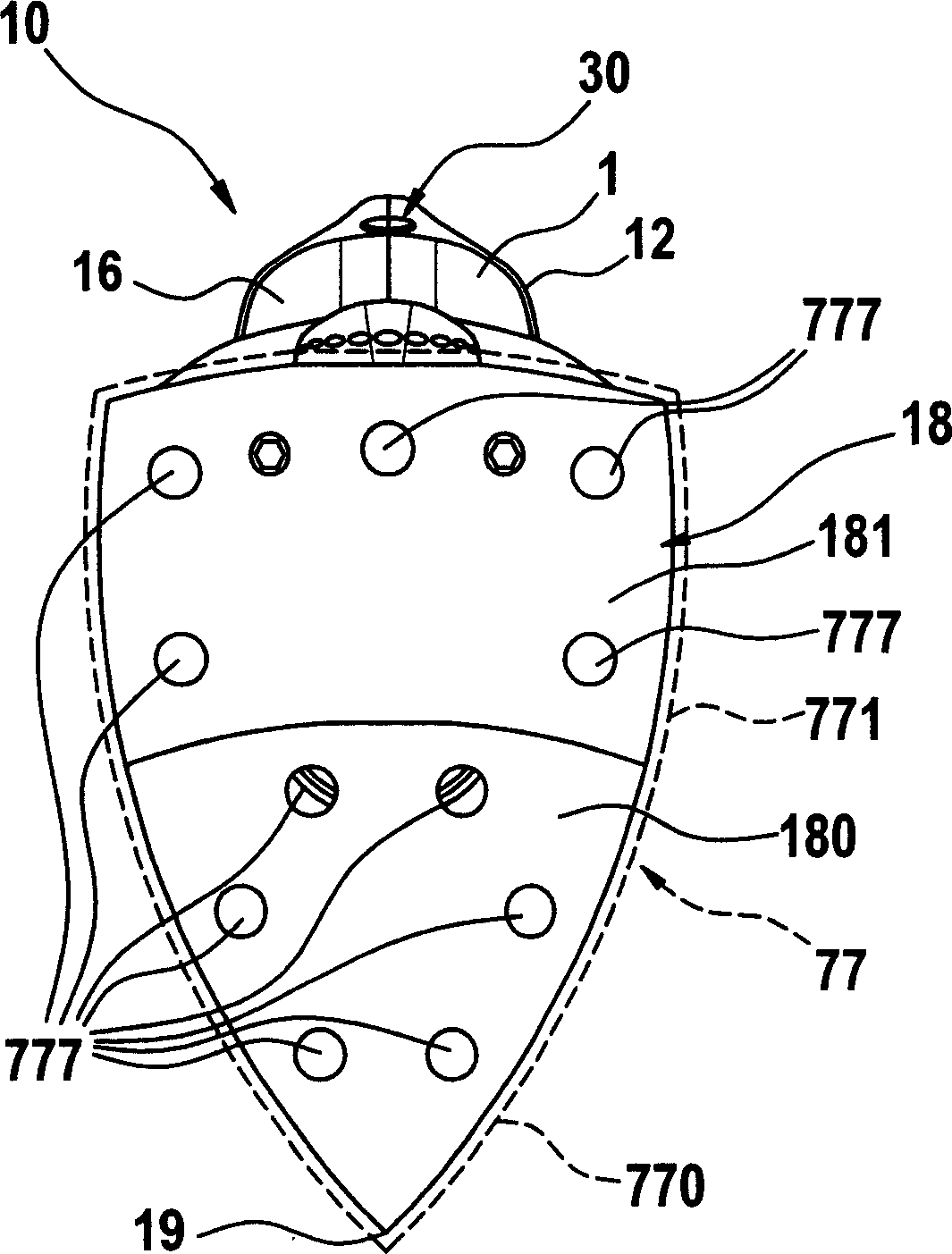

[0056] Below the viewing direction, the housing 12 carries an iron-like, triangular-shaped grinding disc 18 whose disc tip 19 points to the right in the viewing direction and defines ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com