Electric machine

A kind of bearing and cylindrical bearing technology, applied in the field of motor, to achieve the effect of smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

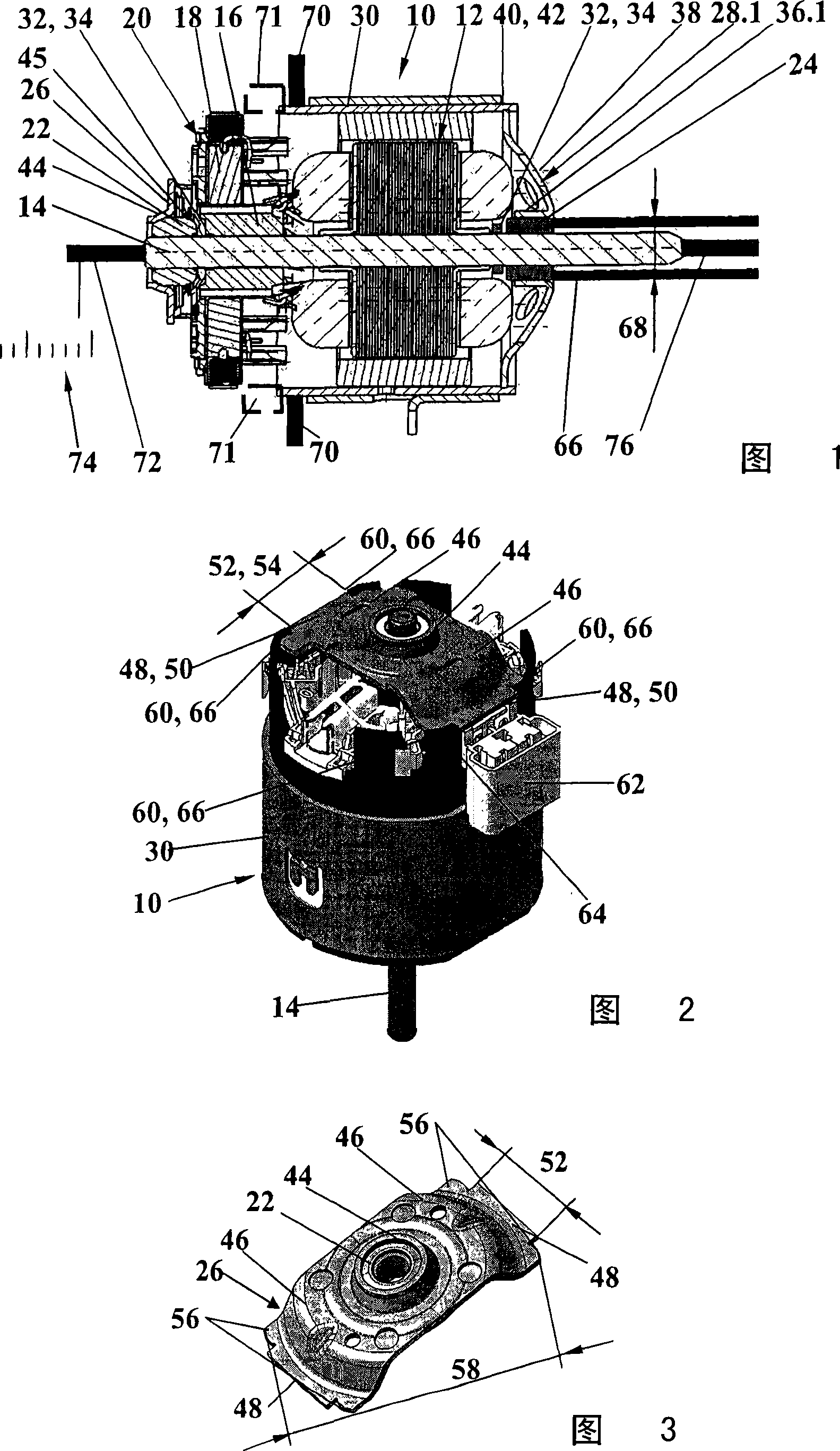

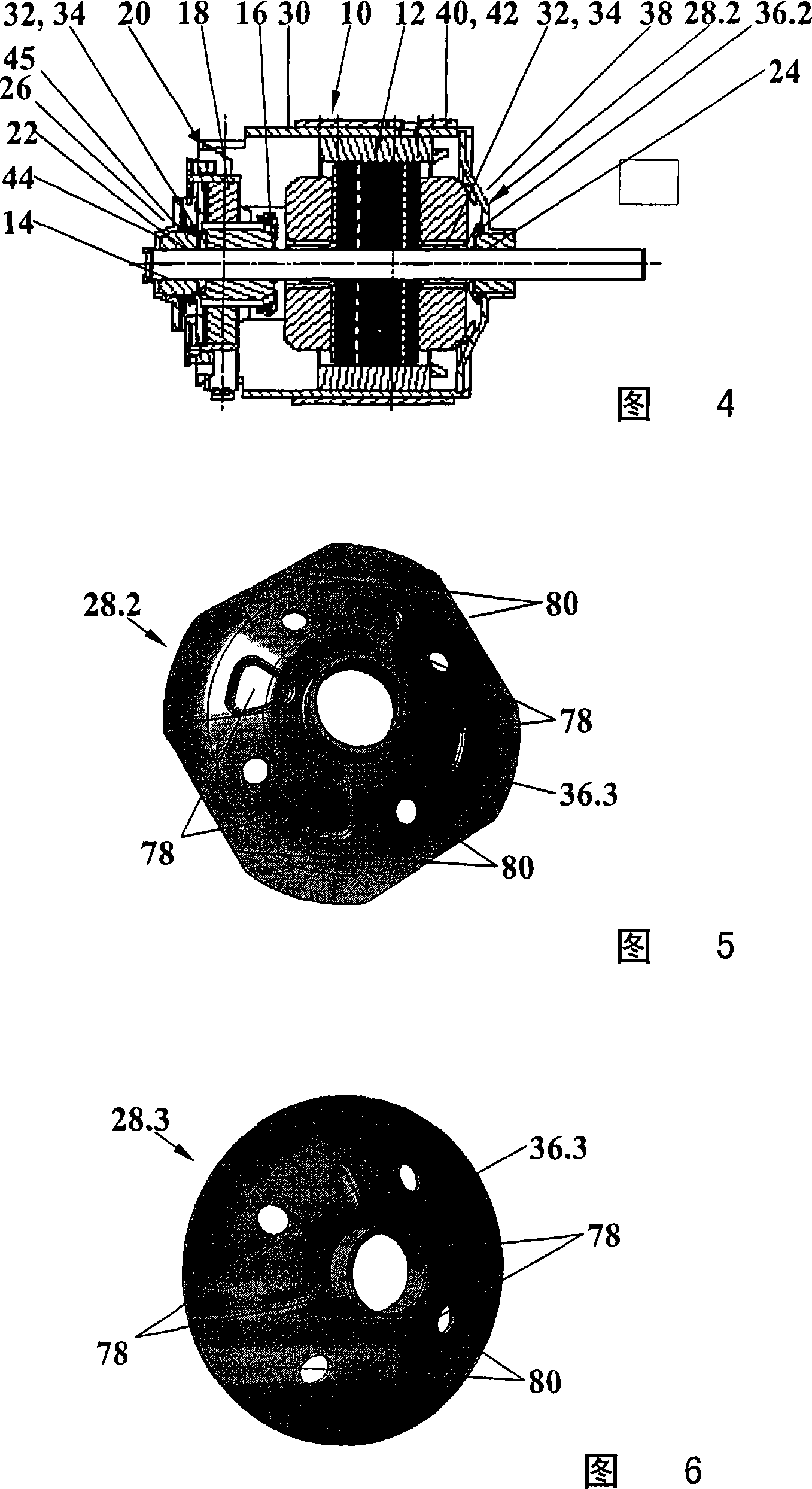

[0025] Figure 1 shows a simplified longitudinal section of a rotating electric machine. The electric machine is an electric motor 10 which is used in motor vehicles, for example, in window lifters, wiper drives, preferably in heating drives and / or fan drives or the like. But it can also be a generator.

[0026] The electric motor 10 has a wound armature 12 which is arranged on a shaft 14 . The armature 12 is connected to a commutator 16 which in turn is connected to the brushes 18 of a brush holder 20 . Instead of the rectifier 16 , a current collector of the generator can also be provided.

[0027] The shaft 14 is supported in spherical cap bearings 22 and cylindrical bearings 24 . In the present embodiment, the bearings 22 , 24 are sintered bearings or plain bearings impregnated with oil. The spherical cap bearing 22 is arranged on a bearing pressure plate 26 in the area of the brush holder 20 . The cylindrical bearing 24 is arranged on the output side in the end shie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com