Dust removal device based on rice mill

A dust removal device and rice milling machine technology, applied in the field of rice milling machines, can solve the problems that rice dust cannot be completely raised and discharged, the dust removal effect is poor, and it is easy to dirty the staff, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

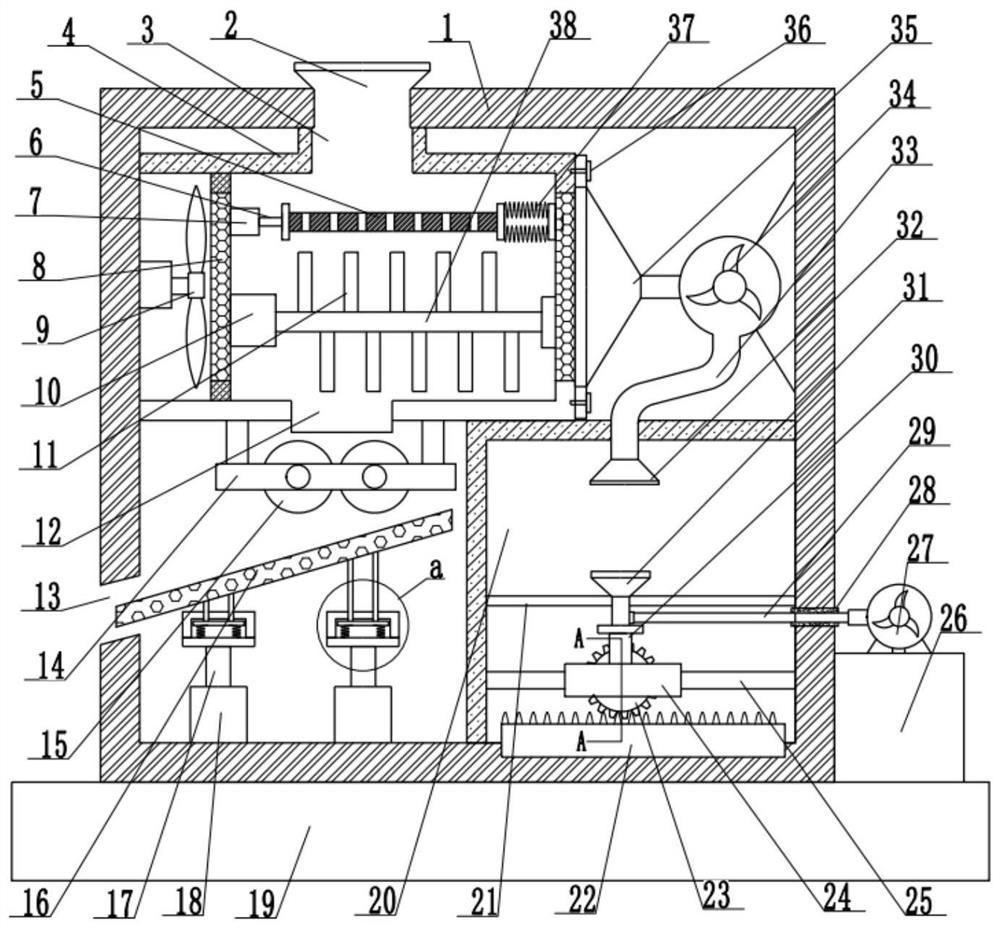

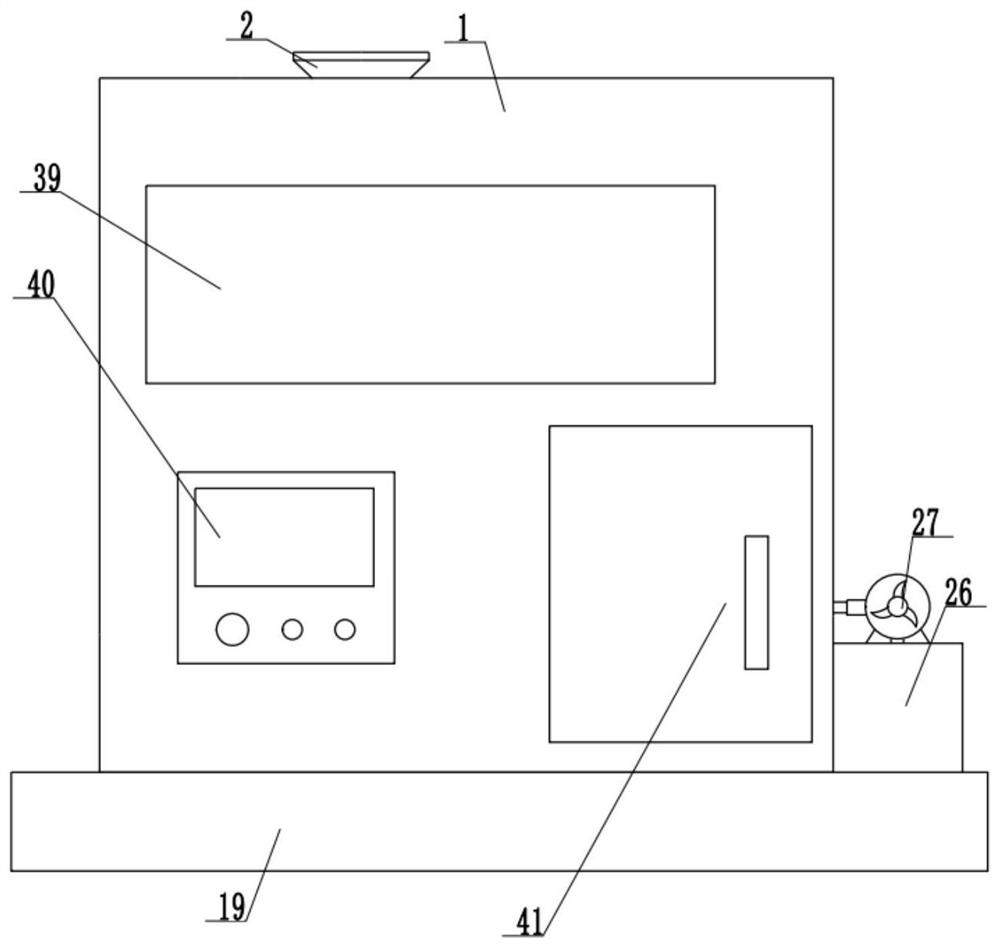

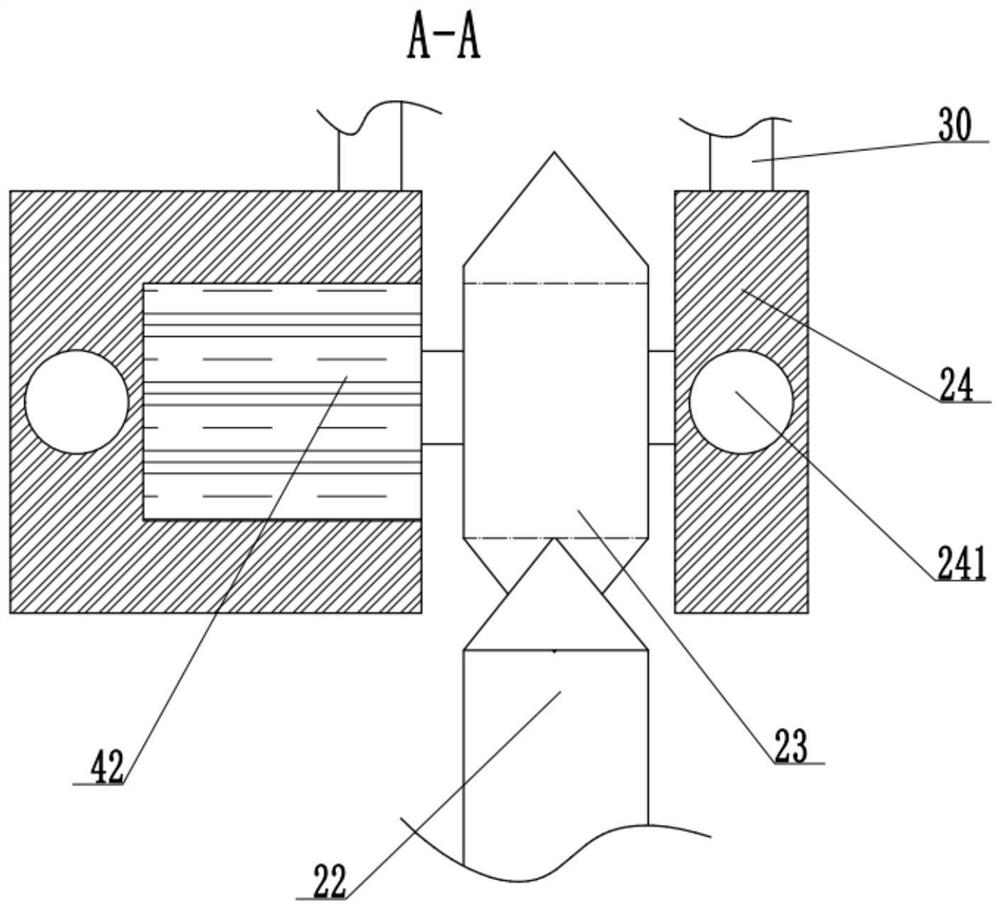

[0027] see Figure 1 to Figure 3 , a dust removal device based on a rice mill, comprising a rice mill housing 1, a stirring housing 4, a first servo motor 10, a fan 9, a drive gear 23, a dust collection valve 35 and a high-pressure water spray valve 31, the The stirring shell 4 is connected to the feeding port 2 inlaid on the top of the rice mill shell 1 through the stirring shell feed port 3, and a rolling roller 15 is arranged below the blanking port 12 fixedly connected to the bottom of the stirring shell 4, so that The number of the rolling rollers 15 is two, and they are connected to the stirring shell 4 through a bracket 14. The first servo motor 10 is embedded in the inner wall of the stirring shell 4, and is connected to the stirring shaft 38 through a coupling. The stirring shaft 38 surfaces are fixedly connected with some stirring paddles 11, and the stirring paddles 11 can prevent the feeding port 12 from being blocked on the one hand, and can raise the dust attache...

Embodiment 2

[0034] see figure 1 and Figure 4, a kind of dedusting device based on a rice mill, also includes a rolling roller 15, a second sieve plate 16 is arranged below the rolling roller 15, and a plurality of filter holes are provided on the surface of the second sieve plate 16, and the The diameter of filter hole 1 is smaller than the diameter of rice, which can filter out the smaller granular impurities in the rice and improve the quality of rice. The bottom of the second sieve plate 16 is connected to the support plate 173 through the support column 174, and the support The plate 173 is embedded in the cavity provided inside the buffer seat 171, and the bottom of the support plate 173 is connected to the inner wall of the cavity through the first spring 172, and the buffer seat 171 is connected to the second cylinder 18 through the second piston rod 17, and the second cylinder 18 The second piston rod 17 drives the second sieve plate 16 to move up and down according to a certain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com