Automatic torpedo ladle inserting and pulling system and inserting and pulling method

An automatic plug-in and torpedo technology, which is applied in the connection/disconnection of connection devices, coupling devices, electrical components, etc., can solve the problems of inconvenient automation, uncertain position of the female head of the plug, and increasing the design difficulty of the plug-in mechanism. , to achieve the effect of improving reliability, maintenance cost and workload, and improving anti-environmental interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

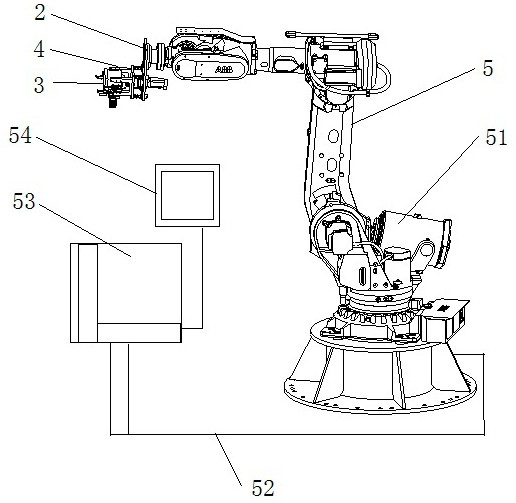

[0043] The invention provides a torpedo can robot automatic insertion and extraction system, which is mainly composed of an insertion and extraction mechanism, a robot system, a laser vision system, a control system and the like.

[0044] The torpedo can plug female head 1 is installed on the torpedo can;

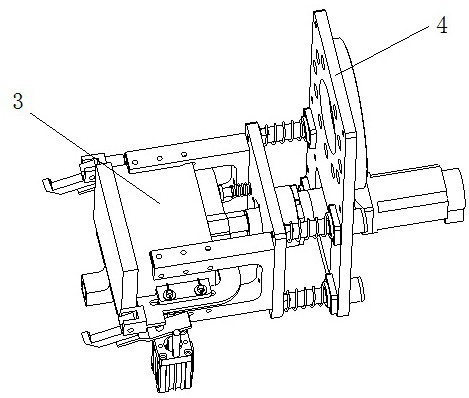

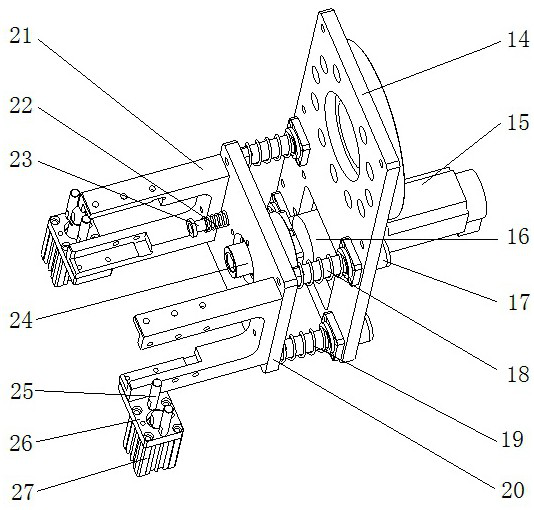

[0045] as attached figure 1 As shown, the male torpedo plug 3 is installed on the execution end of the plug-in mechanism 4, and the fixed end of the plug-in mechanism is connected to the industrial robot system 5 through the connecting flange 14, and the connecting flange 14 is equipped with a laser vision system 2;

[0046] The laser vision system uses a three-dimensional intelligent contour scanning sensor, and the 2140 series is selected according to the detection accuracy and field of view requirements. By scanning the female head of the plug, the position coordinates of the female head of the plug are detected, which guides the robot to perform the plugging and unplu...

Embodiment 2

[0059] According to the torpedo tank robot automatic plugging system described in embodiment 1, its plugging method:

[0060] (1) When the torpedo tanker arrives at the pouring room, the body position detection part of the system prompts and guides the driver to park the vehicle at the designated position, ensuring that the deviation of the torpedo tanker in the track direction is within ±300mm;

[0061] (2) The laser vision system 2 scans the torpedo tank car, finds out the position of the female head 1 of the torpedo tank plug, and calculates the coordinate value;

[0062] (3) The robot moves to the specified position according to the coordinates given by the laser vision system 2, and aligns the torpedo can plug male 3 with the torpedo can plug female 1;

[0063] (4) The locking cylinder 27 moves upwards, compressing the spring 22;

[0064] (5) The servo motor 15 starts to drive the screw 12 to rotate, and when the specified torque is reached, the servo motor 15 stops, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com