Method for mounting blast furnace framework structure by utilizing transverse hoisting beam

A technology of frame structure and installation method, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of inability to hoist, increase the construction cost, prolong the construction period, etc., achieve convenient and fast construction, extend the working radius, and expand the hoisting. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

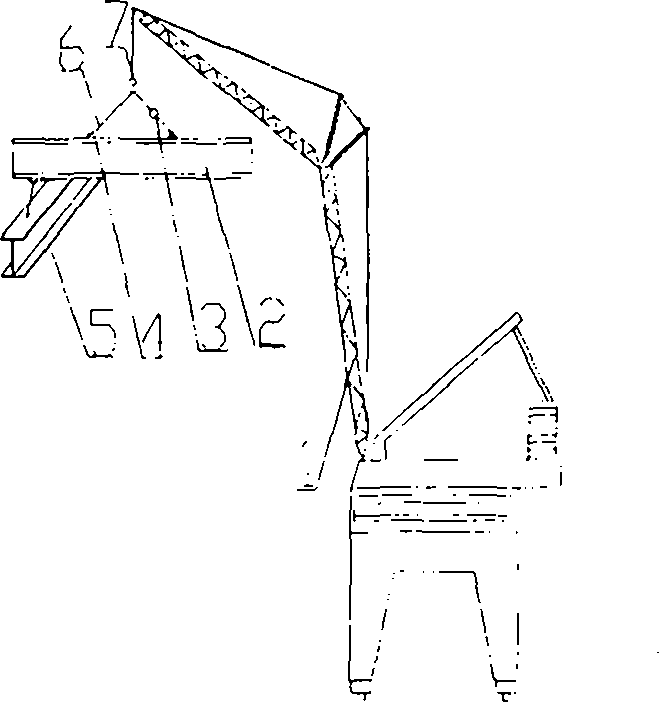

[0007] Embodiment one: see figure 1 , it is characterized in that: first make an I-shaped cross-hung beam 2 with a length of 15m, said cross-hung beam 2 is made of a steel plate, on the longitudinal centerline of the flange plate on the cross-hung beam 2, at a distance from the cross-hung beam 2 At the position of 2m from the transverse centerline, weld a lifting lug 4 on each side, on the longitudinal centerline of the lower flange plate of the transverse hanging beam 2, weld a lifting lug 4 at a position 1m from the end of the transverse hanging beam 2, before hoisting, First weld the lifting lug 4 on the component 5 to be hoisted, and connect it to the bottom of the horizontal suspension beam 2 with a steel wire rope 6, and then use a 3m long steel wire rope 6 at one end of the connecting component 5 to weld it on the horizontal suspension beam 2 The lifting lug 4 on the flange plate is connected to the hook head of the 4000t.m tower crane 1, and the other end without the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com