Nuclear power steam generator pipe detection robot

A steam generator and pipeline detection technology, applied in the field of detection robots, can solve problems such as polluted steam generators, low detection efficiency, troublesome application, etc., and achieve the effects of flexible and reliable control, convenient energy acquisition, and clean application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

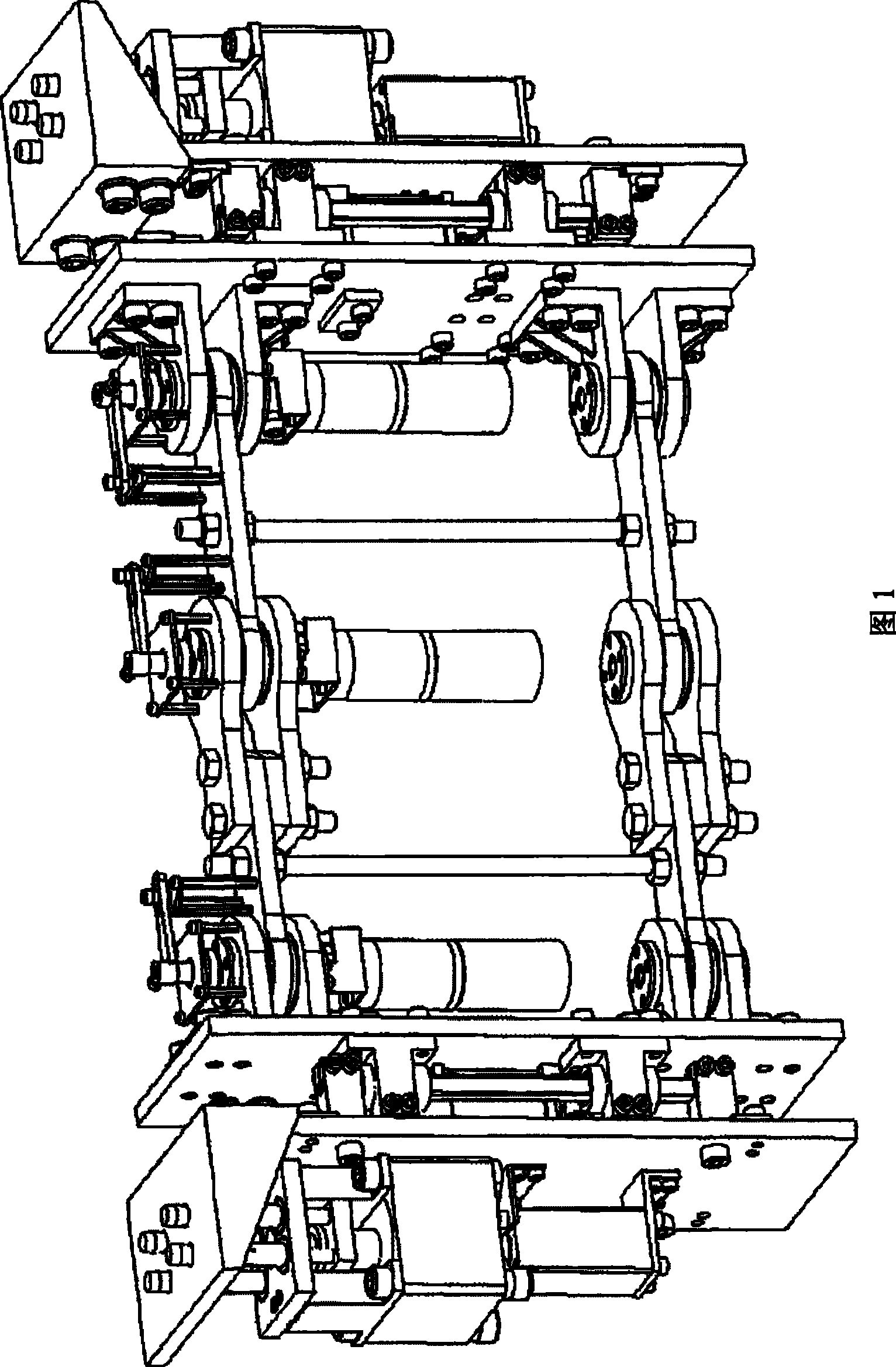

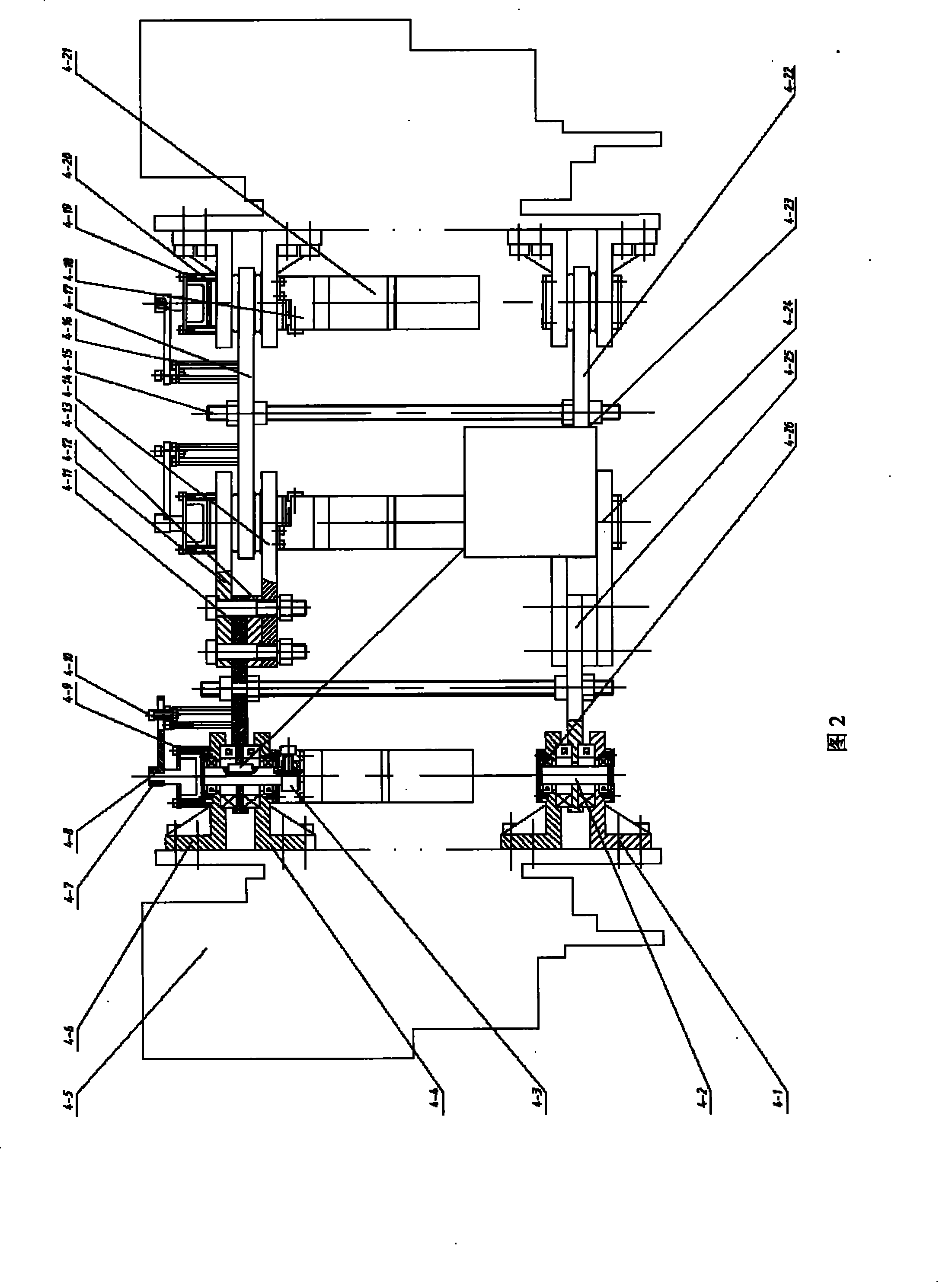

[0021] The composition and assembly method of the nuclear steam generator pipeline inspection robot are as follows:

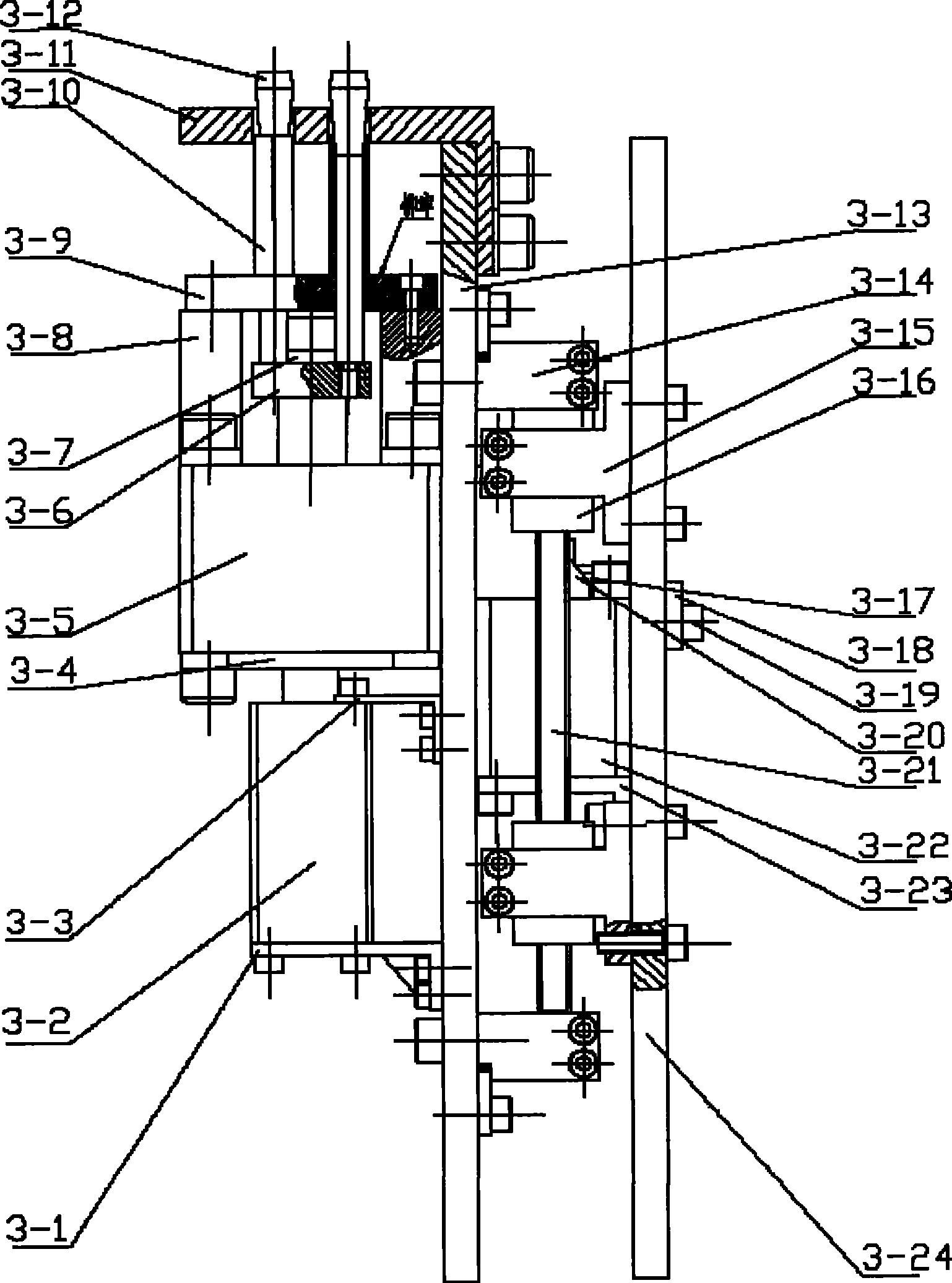

[0022] combine image 3 , first the tensioning cylinder 3-5 and the support member 3-8 are fixed by screws, and then the tie rod connecting plate 3-6 and the gasket 3-7 are fixed to the cylinder rod of the tensioning cylinder 3-5 by screws. The expansion flap 3-10 is fixed on the expansion flap fixing plate 3-9 by riveting, and then the expansion flap fixing plate 3-9 is fixedly connected with the support member 3-8 with screws. Then the connecting rod 3-12 is passed through the expansion flap 3-10 one by one, and is fixed on the pull rod connecting plate 3-6 with the screw thread at its end, and glues to prevent loosening. The push-up cylinder 3-2 is fixed on the fixed plate 1 3-13 by screws on the upper 3-3 and the lower 3-1 of the push-up cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com