Printing water-based coating varnish manufacturing apparatus

A technology for manufacturing equipment and water-based coating, applied to mixers, mixing methods, mixers with rotating stirring devices, etc., can solve problems such as low production efficiency, improve production efficiency, reduce equipment costs, and increase working radius Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

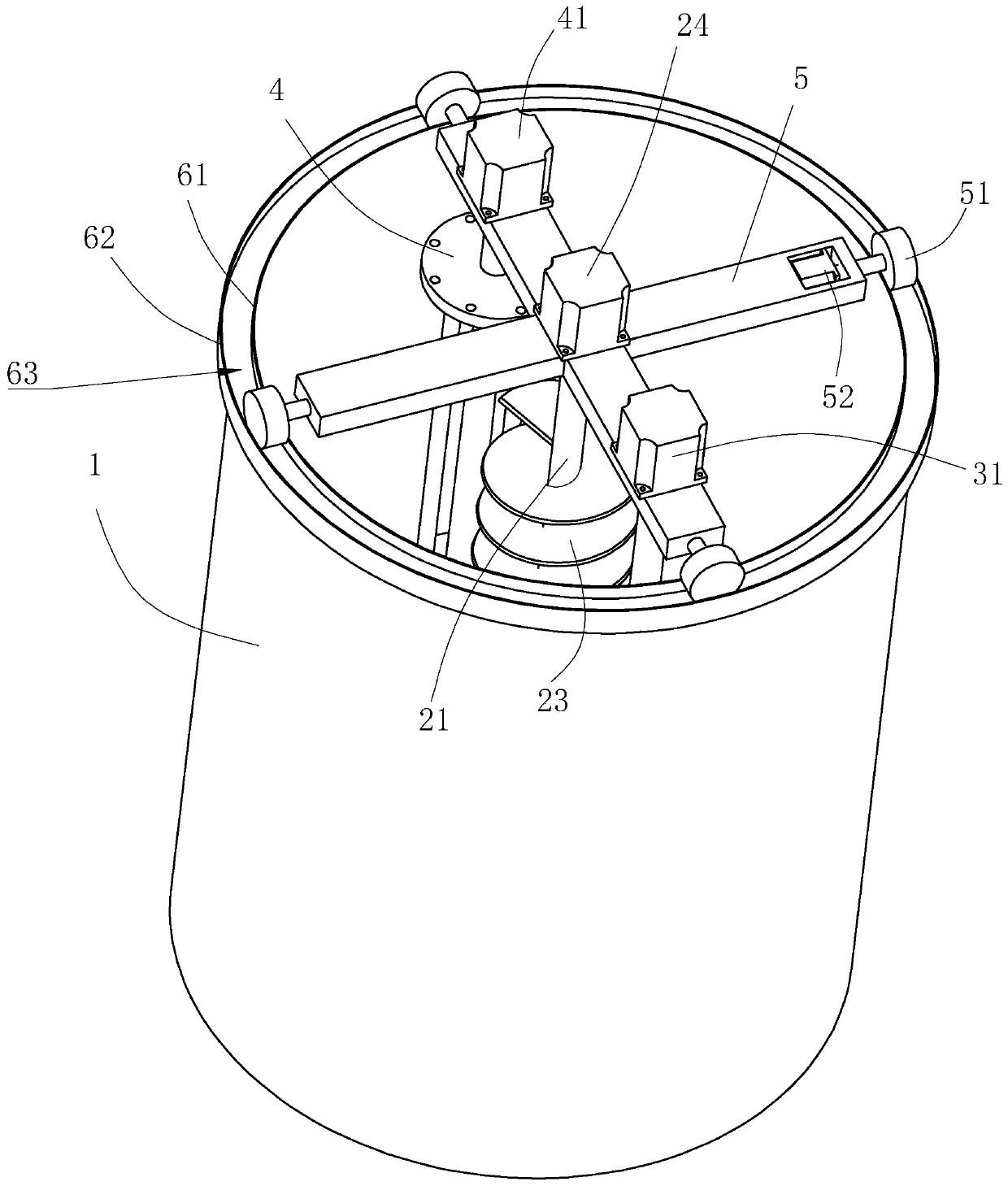

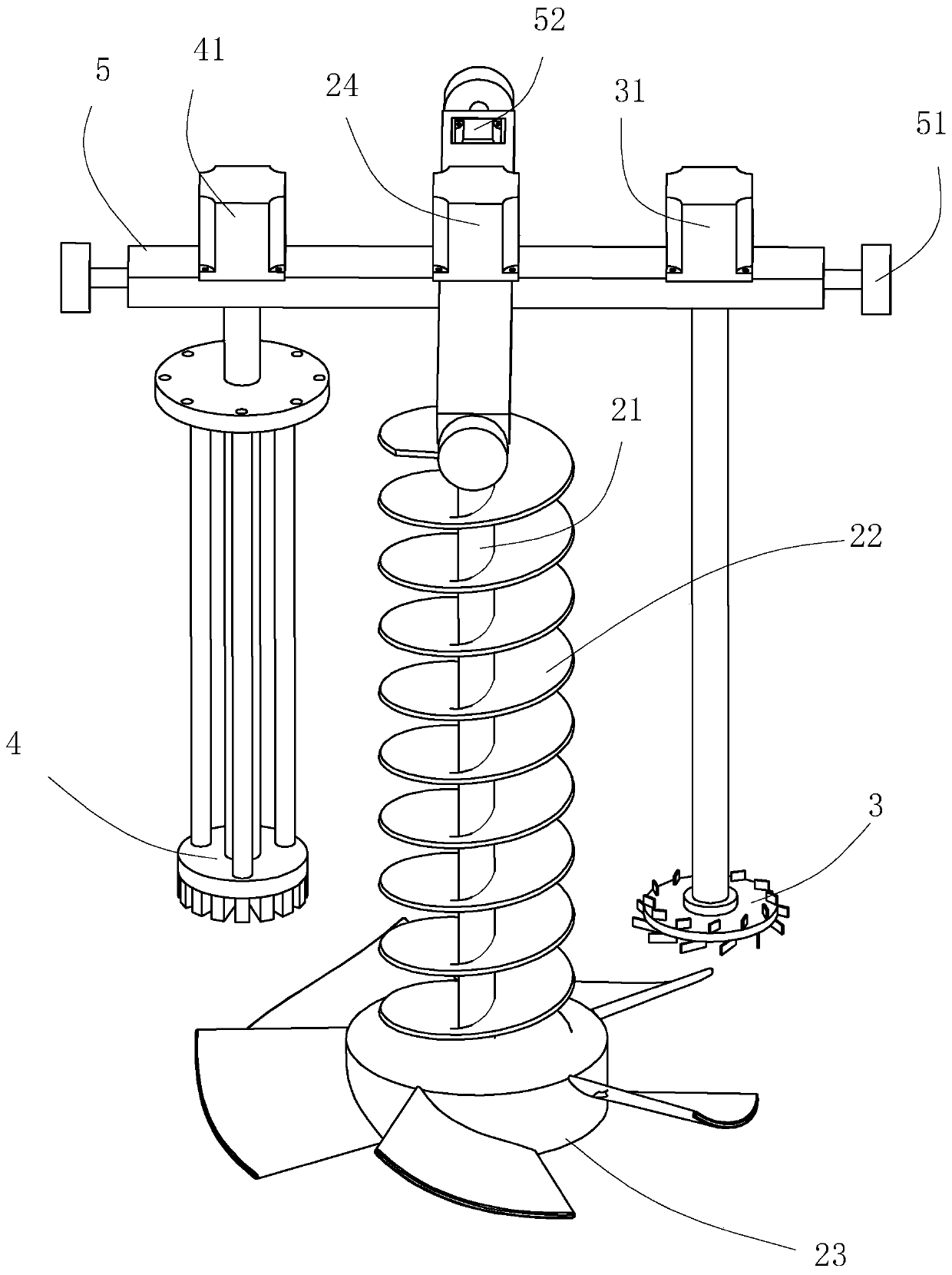

[0030] Such as Figure 1 to Figure 2 As shown, a kind of printing water-based coating varnish manufacturing equipment disclosed by the present invention includes a cylindrical production kettle 1, and the opening of the production kettle 1 is formed with inner ribs 61 and The outer rib 62 forms an annular positioning groove 63 on the upper end surface of the production kettle 1 through the inner rib 61 and the outer rib 62 .

[0031] The opening of the production kettle 1 is provided with a cross-shaped load-bearing frame 5, and the four ends of the load-bearing frame 5 are rotatably connected with positioning wheels 51. The positioning wheels 51 are placed in the positioning groove 63, and the axis of the positioning wheels 51 faces the load-bearing frame 5. The center supports the load-bearing frame 5 by the upper end surface of the production kettle 1. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com