Operating mechanism of vehicle-mounted highway guardrail pile driving and pulling machine

A technology of working mechanism and highway guardrail, which is applied in the direction of roads, roads, sheet pile walls, etc., can solve the problems of large vibration, short stroke, complicated operation, etc., and achieve the effect of small vibration, large working radius and fast running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

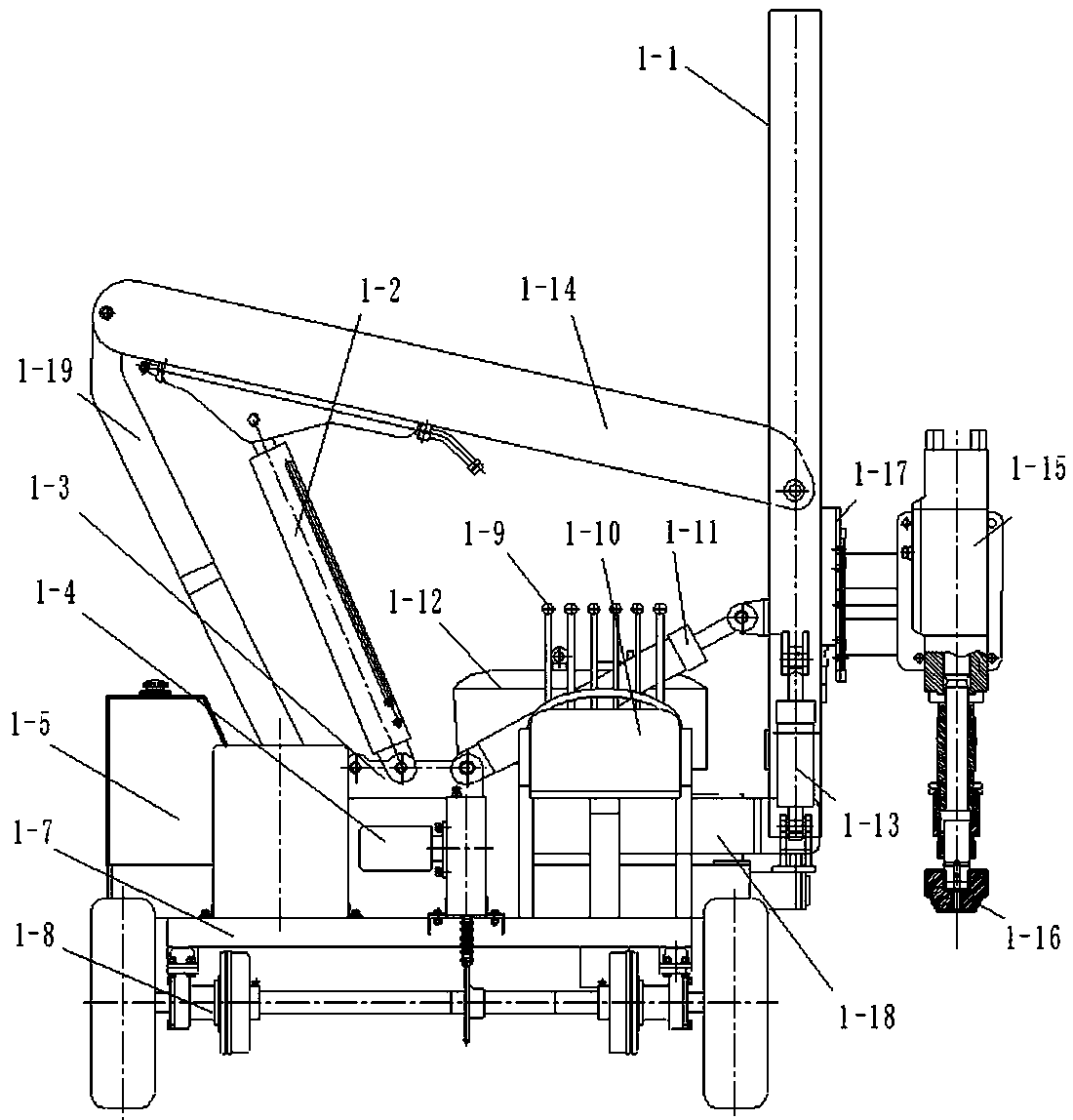

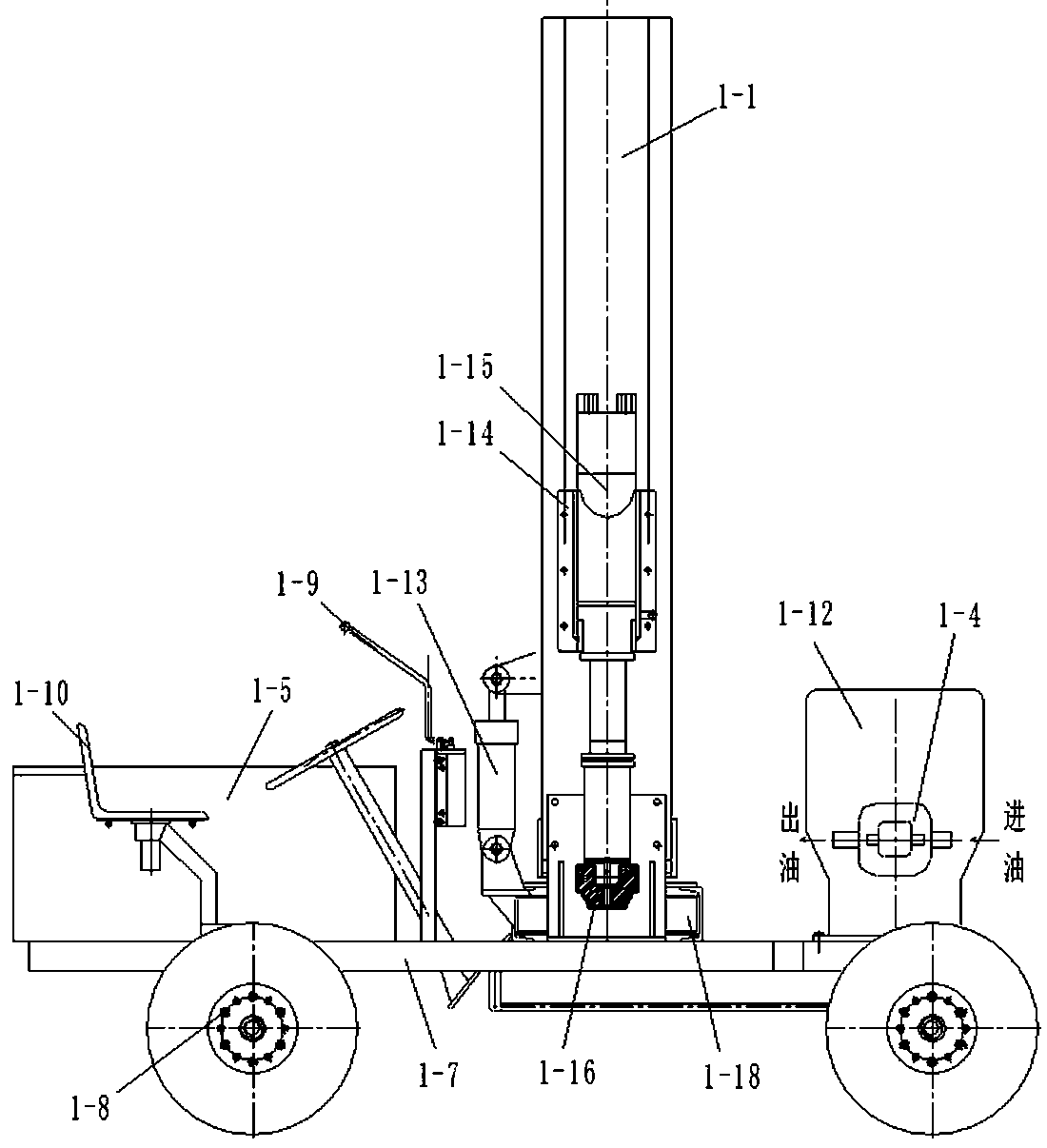

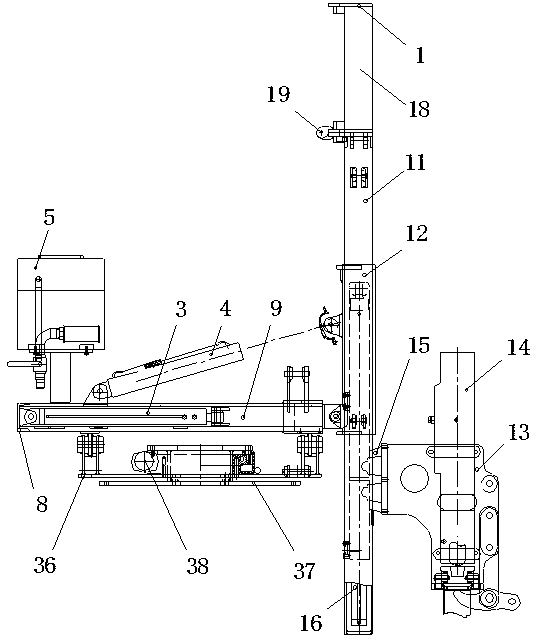

[0062] Example 1: In image 3 , Figure 5 with Figure 15 Among them, the working mechanism includes: a column, a hydraulic oil tank 5, a limit frame 41, a pile holder 6, a lifting device, a horizontal device, a left and right device, a pitching device, a working device and a turning device; The hydraulic oil tank 5 is sequentially connected with the limit frame 41 and the pile holder 6 at the bottom of the column; the working device is connected with the lifting device on the column, and the lifting device slides up and down along the column, and drives the working device to move up and down; the column passes through the pitching device Hinged to one end of the transverse device, the upright column can move laterally with the transverse device, and can use the transverse device as a fulcrum for pitching movement; the bottom of the transverse device is hinged on the slewing device, and the left and right devices are hinged between the transverse device and the slewing device...

Embodiment 2

[0085] Example 2: In image 3 with Figure 4 , the working device is in the pile pulling state.

Embodiment 3

[0086] Example 3: In Figure 5 with Image 6 , the working device is in piling state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com