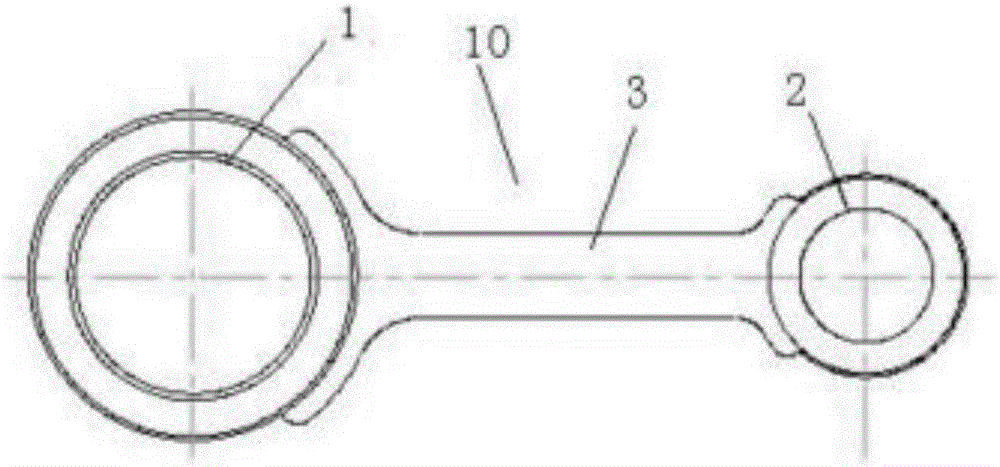

Compressor connecting rod and manufacture method thereof

A manufacturing method and compressor technology, which is applied in the field of compressors, can solve problems such as wear, and achieve the effects of improving wear resistance, improving overall wear resistance, and reducing scratches and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

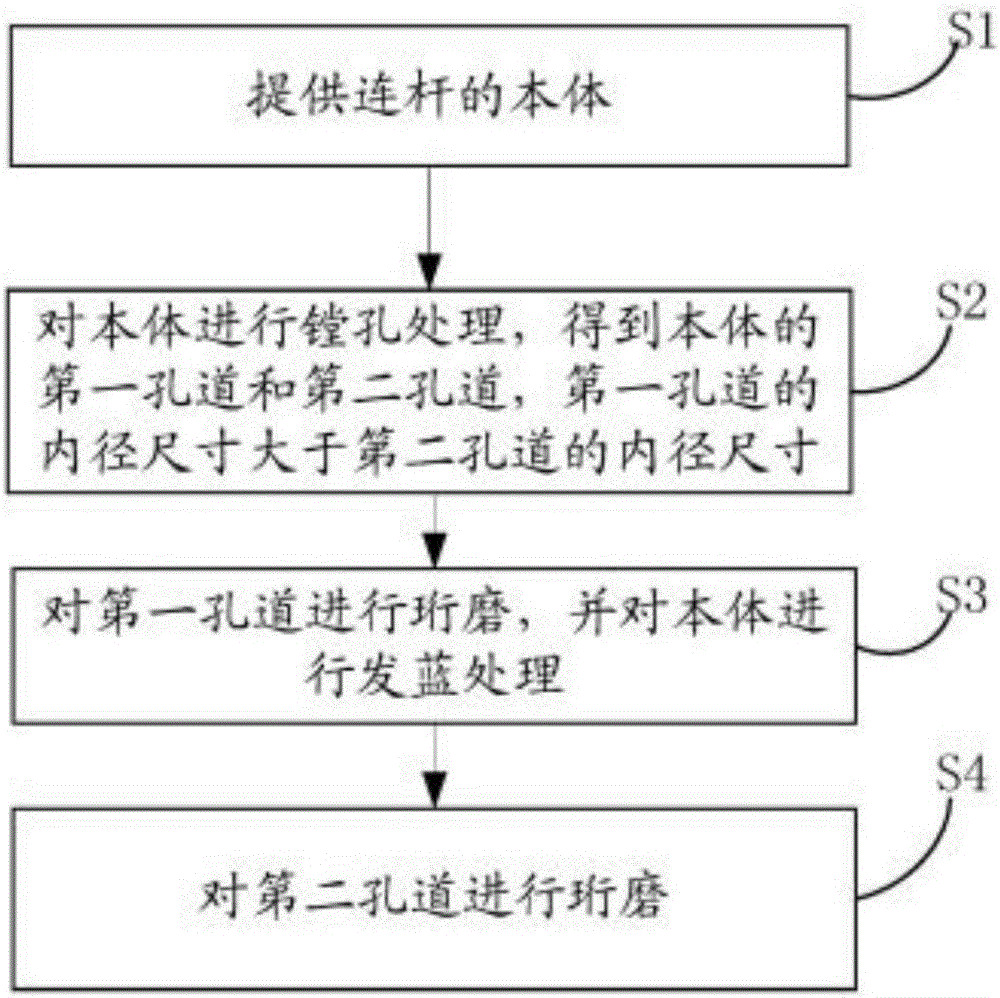

Method used

Image

Examples

Embodiment 1

[0054] The iron powder raw material is pressed and sintered to obtain a powder metallurgy connecting rod blank, and the hardness of the connecting rod blank is 44HRB. The two ends of the connecting rod are rough-bored and fine-bored to obtain large and small holes, the size of the large hole is 13.970mm, and the size of the small hole is 6.970mm. The large holes are honed, then cleaned and then steam treated. The water vapor treatment step is as follows: first, blow nitrogen at 600° C. and keep it for 2 hours, and then pass water vapor for 2 hours of bluing treatment. The size of the large hole after treatment is 14.016mm. Then the small hole is honed to remove the bluish layer on the inner wall of the small hole. The size of the small hole after honing is 7.003mm. Wash the body after handling. Then the body is phosphating to form a phosphating layer on the inner wall of the small hole. Finally, the connecting rod is brushed to obtain a large-pore reinforced powder metall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com