Engine crankshaft storage device

A storage device and engine technology, applied in the direction of tool storage devices, manufacturing tools, etc., can solve the problems of increasing crankshaft production cost and increasing product scrap rate, and achieve the effects of low production cost, control product scrap rate, and reliable safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

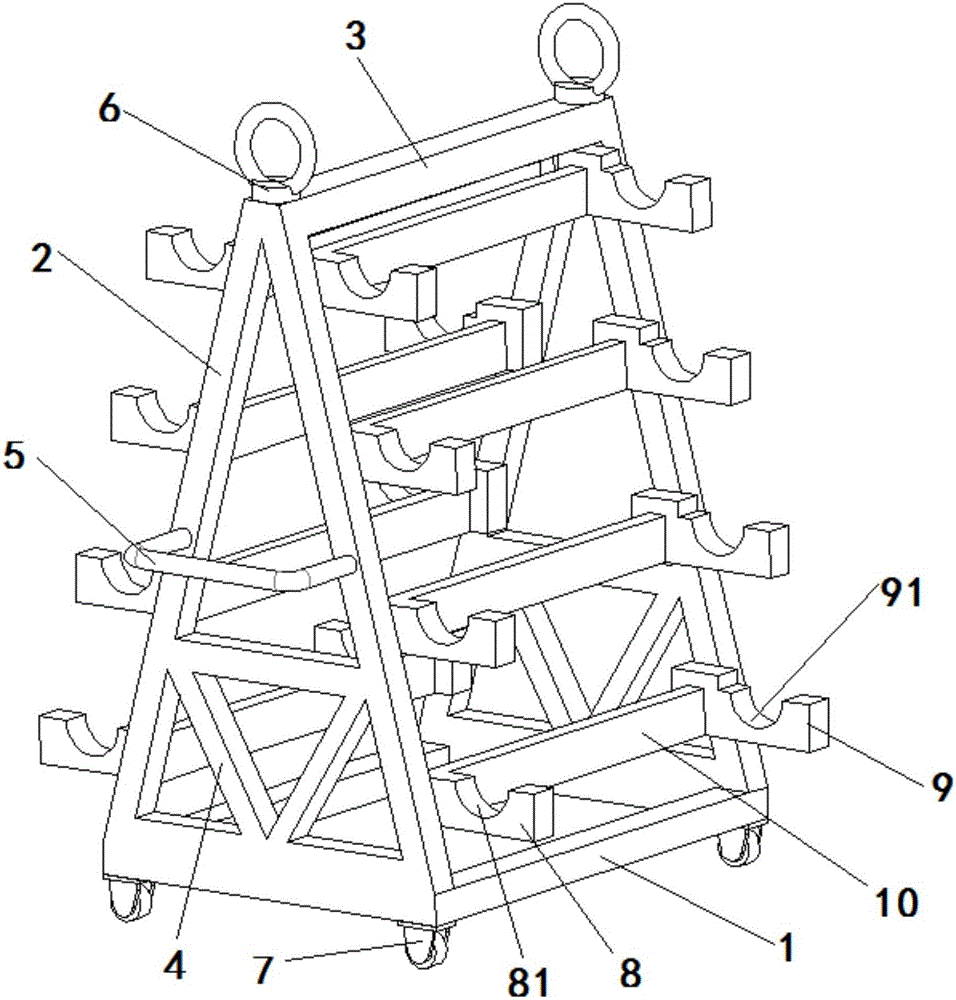

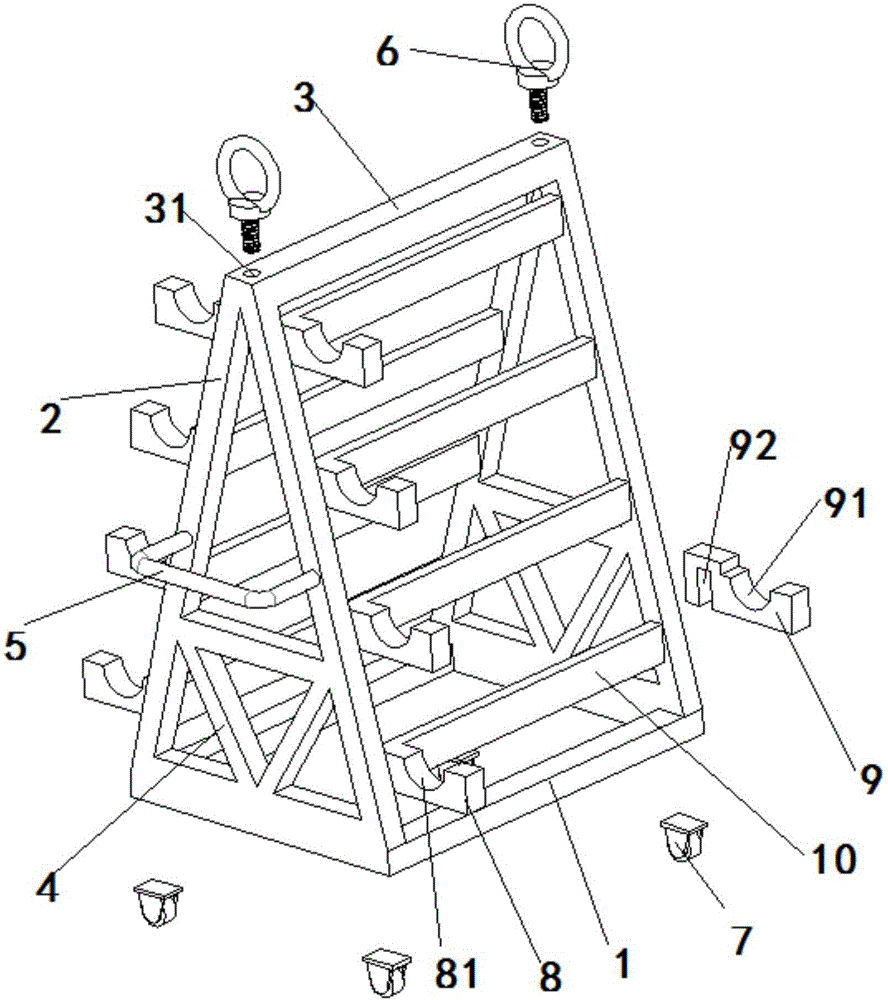

[0016] Such as Figure 1 to Figure 2 The engine crankshaft storage device shown includes a base 1, a support base 2, a connecting plate 3, a reinforcing rib 4, a handle 5, a suspension ring 6, casters 7, a backing plate 8, a sliding plate 9, and the left and right sides of a square base 1 A herringbone support seat 2 is arranged vertically, casters 7 are arranged around the bottom end, a triangular reinforcing rib 4 connected to the base 1 is arranged near the bottom end of the support seat 2, a U-shaped handle 5 is arranged horizontally in the middle, and a connecting foot is arranged at the top. There are connecting plates 3 on both sides, the left and right sides above the connecting plate 3 are provided with threaded holes 31, the threaded holes 31 are screwed with suspension rings 6, and several fixed plates 10 are vertically ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com