Device for increasing resistance and regulating pressure in filling slurry pipeline transportation

A technology for filling slurry and pipeline transportation, which is used in filling materials, safety devices, connections with fluid cut-off devices, etc. The effect of stable flow, easy installation and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

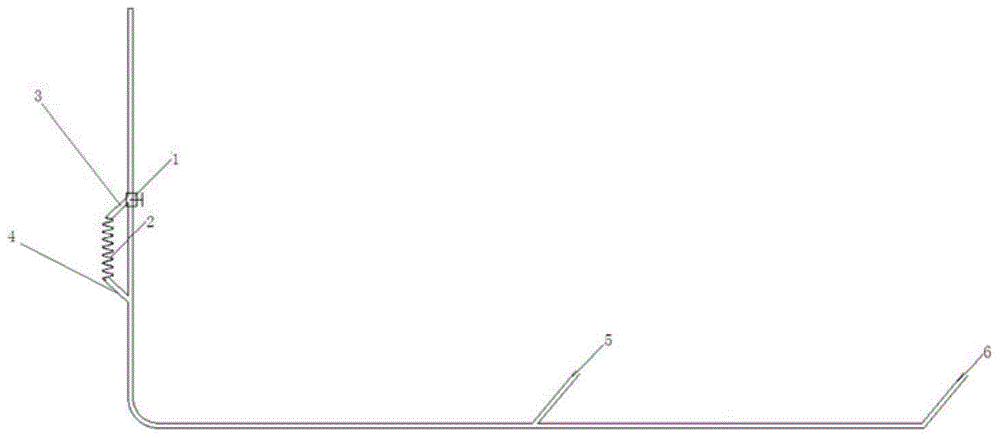

[0023] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments of the description. The present invention provides a device for increasing resistance and pressure regulation in the pipeline transportation of filling slurry. The resistance-increasing and pressure-regulating device is installed on the pipeline in the actual application of the mine.

[0024] The resistance-increasing and pressure-regulating device includes upper and lower shunt gate valve devices and spiral pipes, the upper and lower shunt gate valve devices are installed on the filling pipeline, and the two ends of the spiral pipe are respectively connected to the upper and lower shunt gate valves device.

[0025] The installation method of the resistance-increasing and pressure-regulating device in the filling slurry pipeline transportation provided by the present invention specifically includes the following steps:

[0026] ①Analyze and calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com