Friction material, carbon ceramic brake pad formed through preparing of friction material and preparing method of carbon ceramic brake pad

A technology of friction materials and brake pads, which is applied in the field of carbon ceramic brake pads and its preparation, can solve the problems of short life of brake pads and large wear of friction materials, and achieve stable friction coefficient, high service temperature and small fluctuation of friction coefficient value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

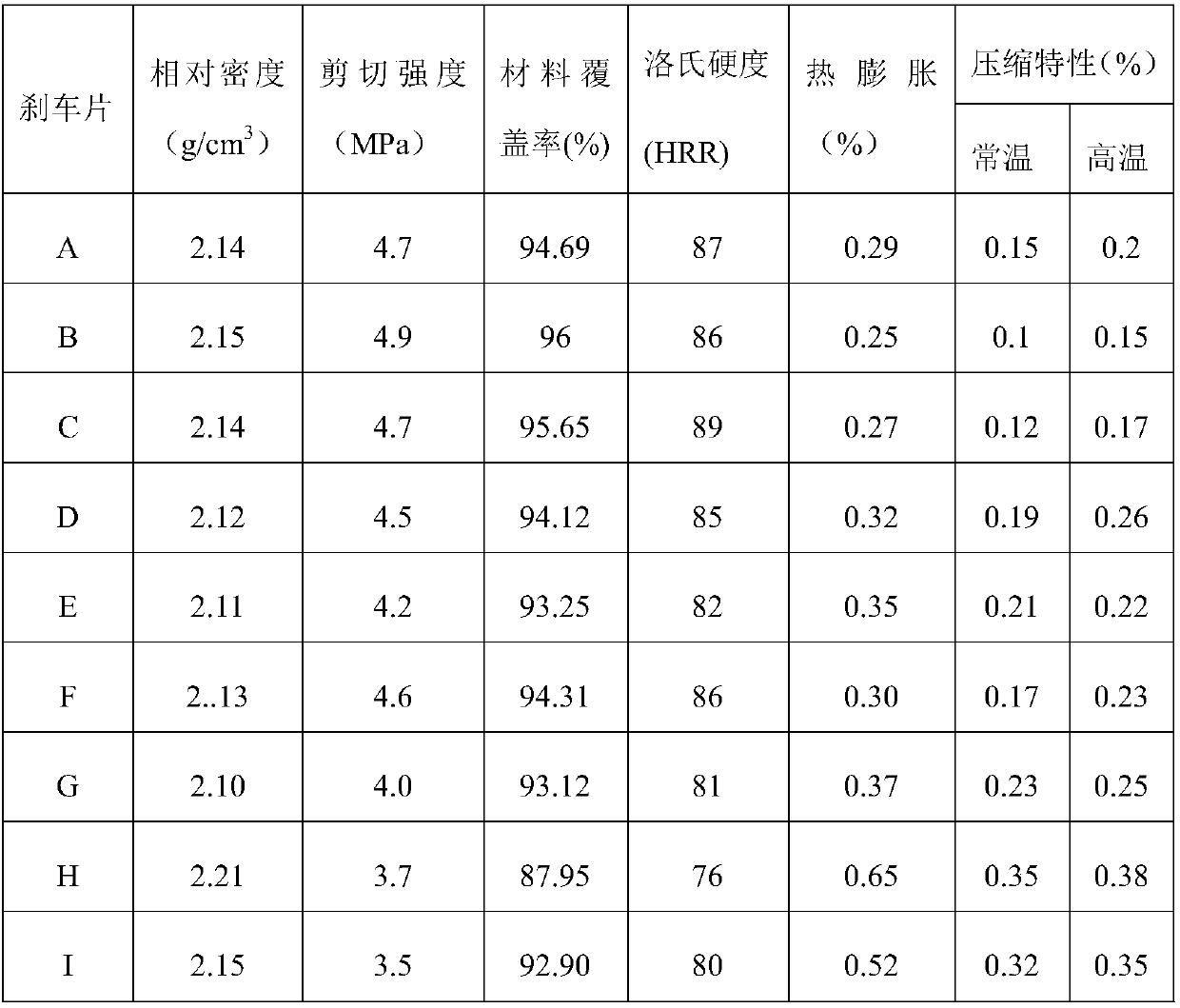

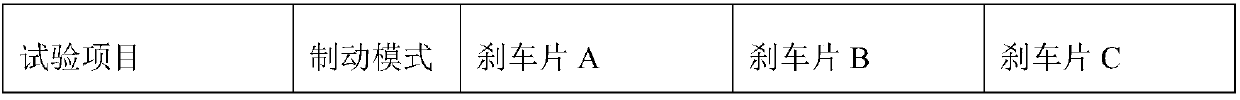

[0024] This embodiment provides a friction material, which includes the following raw materials in parts by weight (1 part by weight is 200g): 13 parts of carbon ceramic fiber, 2 parts of steel fiber, 5 parts of mineral fiber, nitrile rubber modified phenolic resin 15 parts, powdered nitrile rubber 9 parts, petroleum coke 10 parts, barium sulfate 10 parts, polyacrylonitrile fiber 5 parts, heavy magnesium oxide 14 parts, kaolin 12 parts, silicon dioxide 6 parts.

[0025] According to the above ratio, mix the components for 30 minutes to obtain a uniform mixture, place the steel back and the mixture in the mold in turn, set the pressing pressure to 10MPa, and the pressing time to 150s, and then solidify the pressed blank at 180°C 8h, the semi-finished product of the brake pad was prepared, and the semi-finished product of the brake pad was machined into shape, and then the machined and formed semi-finished product of the brake pad was installed with a sound-absorbing plate, a cir...

Embodiment 2

[0027] This embodiment provides a friction material, which includes the following raw materials in parts by weight (1 part by weight is 200g): 12 parts of carbon ceramic fiber, 3 parts of steel fiber, 7 parts of mineral fiber, nitrile rubber modified phenolic resin 13 parts, 6 parts of powdered nitrile rubber, 8 parts of petroleum coke, 14 parts of barium sulfate, 2 parts of polyacrylonitrile fiber, 13 parts of heavy magnesium oxide, 7 parts of kaolin, 4 parts of silicon dioxide.

[0028] Mix the components according to the above ratio for 35 minutes to obtain a uniform mixture, place the steel back and the mixture in the mold in turn, set the pressing pressure to 12MPa, and the pressing time to 200s, and then solidify the pressed blank at 210°C 7h Prepare the semi-finished brake pad, machine the semi-finished brake pad, install the silencer, retainer and alarm on the semi-finished brake pad, and finally make the brake pad B.

Embodiment 3

[0030] This embodiment provides a friction material, which includes the following raw materials in parts by weight (1 part by weight is 200g): 10 parts of carbon ceramic fiber, 5 parts of steel fiber, 6 parts of mineral fiber, nitrile rubber modified phenolic resin 12 parts, 5 parts of powdered nitrile rubber, 8 parts of petroleum coke, 15 parts of barium sulfate, 2 parts of polyacrylonitrile fiber, 10 parts of heavy magnesium oxide, 6 parts of kaolin, 4 parts of silicon dioxide.

[0031] Mix the components for 30 minutes according to the above ratio to obtain a uniform mixture, place the steel back and the mixture in the mold in turn, set the pressing pressure to 15MPa, and the pressing time to 180s, and then solidify the pressed blank at 180°C 10 hours to prepare the semi-finished brake pad, machine the semi-finished brake pad, then install the silencer, retainer and alarm on the semi-finished brake pad, and finally make the brake pad C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com