High-strength and wear-resistant roller bit

A high-strength, high-strength drill bit technology, applied to drill bits, drilling equipment, earthwork drilling and production, etc., can solve problems such as brittle fracture life, achieve the effects of improving service life, reducing drilling costs, and not being easily broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

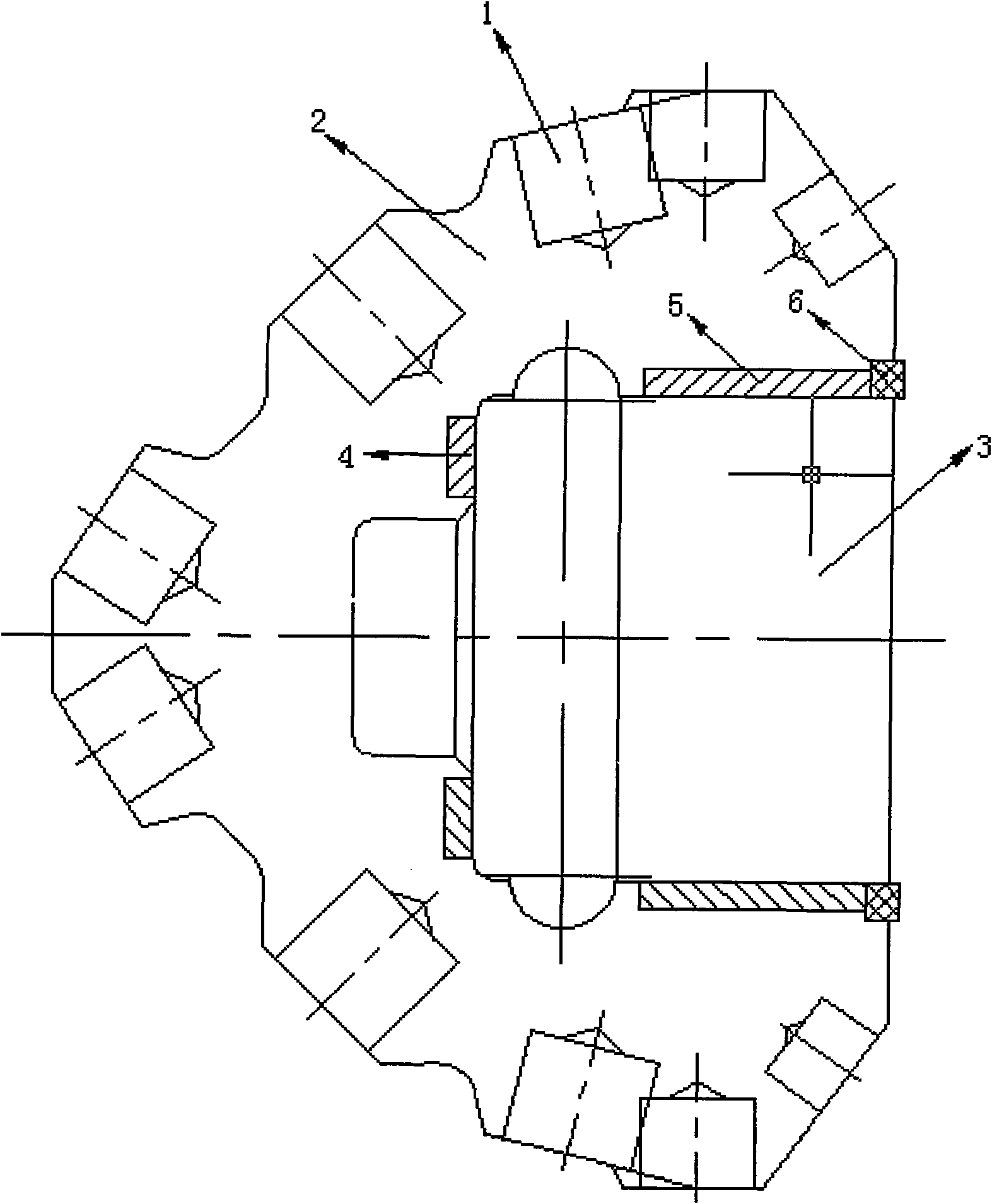

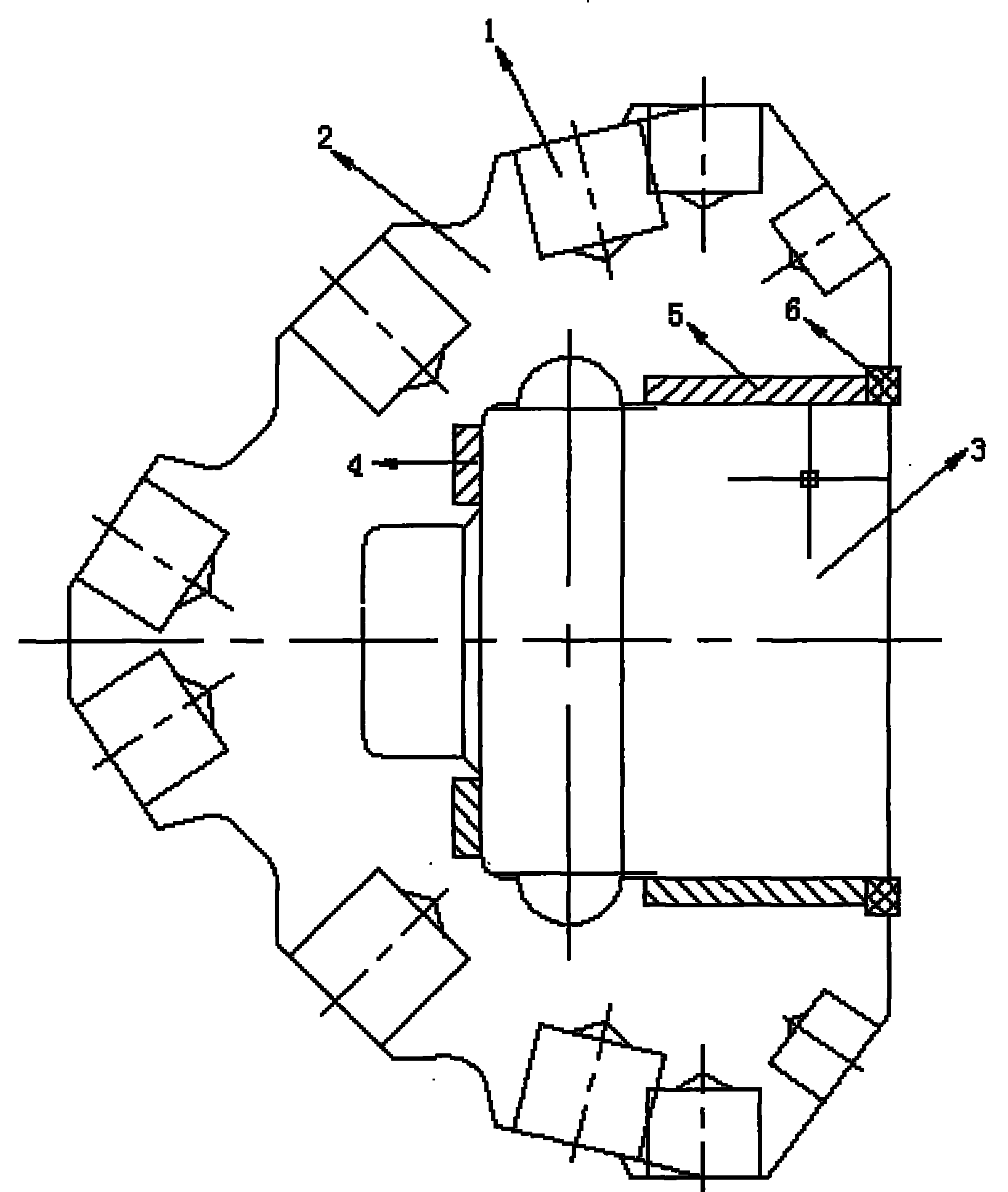

[0012] Example 1, see figure 1 , processed into the cone 2, install the tooth 1 on the cone 2, according to the design requirements, the bottom of the inner ring of the cone 2 and the inner wall are respectively turned to a thickness of 2-6mm; the high-strength and wear-resistant silicon carbide material is used to make ceramics The inlaid ring 4 has a thickness of 2-6 mm, a roughness of 0.8 μm, and a cylindrical shape; a ceramic bush 5 made of high-strength and wear-resistant silicon nitride material, a thickness of 2-6 mm, and a roughness of 0.8 μm , the shape is cylindrical; the cermet sealing ring 6 is made of wear-resistant and corrosion-resistant titanium carbide cermet material, the thickness is 2-6mm, the roughness is 0.8μm, and the shape is cylindrical; the processed ceramic is inlaid The ring 4 is connected to the inner bottom end of the cone 2 by means of thermal mosaic compounding, and the inner wall of the cone 2 is connected to the ceramic bushing 5 by means of t...

Embodiment 2

[0013] Embodiment 2 is the same as Embodiment 1, except that the ceramic insert ring 4 is made of high-strength wear-resistant alumina material, the ceramic bushing 5 is made of high-strength wear-resistant silicon carbide material, and the wear-resistant and corrosion-resistant oxidation The cermet sealing ring 6 is made of zirconium ceramic material.

Embodiment 3

[0014] Embodiment 3 is the same as Embodiment 1, except that the ceramic insert ring 4 is made of high-strength wear-resistant zirconia material, the ceramic bushing 5 is made of high-strength wear-resistant alumina material, and the wear-resistant and corrosion-resistant carbonized The cermet sealing ring 6 is made of silicon cermet material.

[0015] The high-strength wear-resistant roller cone bit of the present invention, when working, the drill bit is connected with the drill string, and the drill string drives the drill bit through mechanical rotation, and transmits the mechanical energy and drilling pressure required for crushing rocks to perform high-speed drilling. At present, the service life of cemented carbide teeth is more than 200 hours, and due to the wear and tear of its cone and tooth palm, most of the service life of the drill bit is less than 60 hours. The high-strength wear-resistant cone drill bit of the present invention can make the use of the drill bit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com