Compound gasket for engine

An engine and gasket technology, applied in the direction of engine components, engine sealing, mechanical equipment, etc., can solve the problems of gaskets, fasteners and contact surfaces wear, poor sealing, etc., to achieve enhanced strength and corrosion resistance, The effect of prolonging the service life and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

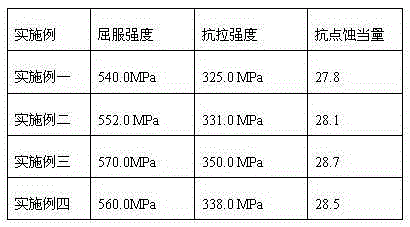

Embodiment 1

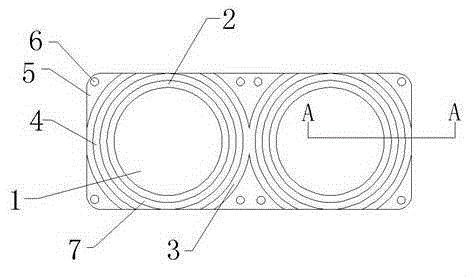

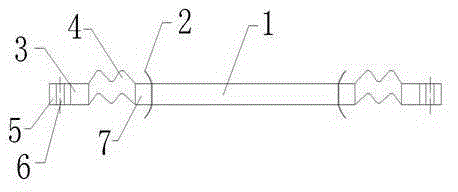

[0026] Such as figure 1 with figure 2 As shown, a combined gasket for an engine includes a metal gasket body 5, the metal gasket body 5 is provided with a plurality of cylinder holes 1 and mounting holes 6, the cylinder hole 1 is inlaid with a sealing ring, so The sealing ring includes a rubber sleeve 2, a first elastic layer 3, a second elastic layer 7 and a stretchable layer 4. The sealing ring and the inner wall of the cylinder hole 1 are connected by a first elastic layer 3, and the other side of the first elastic layer 3 The elastic layer 4 is bonded, the other side of the elastic layer 4 is bonded to the second elastic layer 7, and the other side of the second elastic layer 7 is bonded to the rubber sleeve 2, and the rubber sleeve 2 is exposed The upper and lower ends of the metal gasket body 5 are turned outwards to form a skirt. The outer surface of the rubber sleeve 2 is coated with a polytetrafluoroethylene layer. The telescopic layer 4 is provided with a number of fl...

Embodiment 2

[0037] This embodiment is the same as the first embodiment. The difference is that the components of the elastic stainless steel are calculated by weight percentage (the following% are all expressed by weight percentage): 0.17% for carbon, 7% for nickel, and 9% for chromium. , Manganese is 11%, niobium is 0.58%%, vanadium is 0.32%, molybdenum is 1.8%, titanium is 4%, rare earth is 0.53%, the total amount of phosphorus and sulfur does not exceed 0.035%, and the balance is iron and its indispensable To avoid impurities, the preparation process of the elastic stainless steel includes the following steps:

[0038] Step 1. Use an intermediate frequency induction electric furnace for smelting. The order of adding the metal charge is pig iron, scrap steel, ferromolybdenum, ferronickel, ferromanganese, and ferrochrome. When the smelting temperature reaches 1610°C, deoxidize, and then add deoxidizer for secondary deoxidation. After that, ferromolybdenum, ferro-vanadium, ferro-titanium and...

Embodiment 3

[0044] This embodiment is the same as the first and second embodiments. The difference is that the components of the elastic stainless steel are calculated as percentages by weight (the following percentages are all expressed as percentages by weight): 0.14% carbon, 5% nickel, Chromium is 10%, manganese is 9.5%, niobium is 0.65%, vanadium is 0.27%, molybdenum is 1.5%, titanium is 3.7%, rare earth is 0.46%, the total amount of phosphorus and sulfur does not exceed 0.035%, and the balance is iron And the inevitable impurities, the preparation process of the elastic stainless steel includes the following steps:

[0045] Step 1. Use an intermediate frequency induction electric furnace for smelting. The order of adding the metal charge is pig iron, scrap steel, ferromolybdenum, ferronickel, ferromanganese, and ferrochrome. When the smelting temperature reaches 1610°C, deoxidize, and then add deoxidizer for secondary deoxidation. After that, ferromolybdenum, ferro-vanadium, ferro-titan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com